Written By: Lawrence “LT” Tolman

Back in the days of the 8-track tape, bell-bottoms, and lava-lamps, over half of all cars on the road were equipped with a manual transmission. It was said a man could impress his date by how smoothly he could shift through the gears, and the best drivers like “Grumpy” Bill Jenkins could row a four-speed gearbox much quicker than any automatic transmission could ever execute a shift. As time has moved on, the manual transmission has been slowly phased out, only being found in the cheapest econo-boxes, a select few performance cars. Instead, most vehicles come with an automatic transmission, which handles the gear changes for you. Often the shift is so smooth it’s hard for the average driver to even notice when it happens, and the best part is an automatic requires no foot-hand coordination.

The Fluid Coupler

In an automatic transmission, a torque converter provides the main power coupling between the engine and transmission. Hydraulic pressure is used to clamp and release various clutch packs which are attached to different gears, and depending on which set of clutches is activated, you get different gear ratios. Most automatics have between four and six forward speeds, but in recent years it’s been more common to see eight or even ten-speed automatics. Due the higher torque output, the transmissions found behind diesel engines are much larger and stronger than their counterparts attached to gas engines, but once you start raising the power of the engine, even the best factory transmissions can be found lacking. Due to the rise in popularity of diesel performance, there are a ton of solutions to fix various issues, but it can be tricky to know exactly what you need, what each part does, and at what power level parts begin to fail.

Torque Converter Options

The torque converter is the first thing power from the engine goes to, and in most applications a stock version won’t handle much power. A replacement converter can cost anywhere from $300 to $2,000, and there are lots of ways to configure it, and the right combination can make or break your build. Choose correctly, and you will have a quick truck with great street manners, but if you choose wrong, your drivability will suffer, trans temps will be too hot, and the truck will be much slower off the line.

Due to the nature of fluid coupling, there is an inherent amount of slip in a torque converter. To combat this, all modern diesels use a clutch style lockup converter which engages at certain times to provide a direct link between the engine and trans, eliminating any slip (one exception to this rule is the 68RFE, as its torque converter clutch is a constant slip design). This direct link can help acceleration once the truck is moving and the turbos are already spooled up, but the torque capacity of a stock converter lockup clutch wont handle much more than a hot tune. A converter with additional clutches over stock like the ATS TripleLock for the Dodge 48RE is a great solution for a slipping clutch. A triple disc converter isn’t just for a race truck either; if you spend any time hauling a heavy trailer the increase in holding power is almost necessary.

One option you’ll see when ordering a converter is the choice to add a billet stator, which is an internal part that alters the path of the fluid and provides a torque multiplication effect. The stock cast stators are OK for stock-like conditions, and how you use your truck dictates which option you need; if you ever do boosted launches, burnouts, or other activities which require you to spool up the turbos before moving for more than a couple seconds, a billet stator is a must, since a stock cast piece will fail, and damage the rest of the converter and some of the transmission on its way out.

Stall Speed

The final choice to make when picking out a converter, is stall speed. This is the maximum RPM the engine can turn under power with the truck in gear and not moving. In the gas world, its common to throw in a “high stall converter” as a performance upgrade, and when the correct speed is chosen for the vehicle, there will be a dramatic improvement in 0-60 times. But it’s important to pick the correct stall speed, not just the highest you can find. It’s all based on your exact combination of parts, with the main variable (in the diesel world) being the turbo size. Ideally, you’ll want to pick a stall speed slightly lower than the RPM of peak torque and around the RPM where the turbo starts to spool.

There is no magic rule for picking the stall speed of a converter, but here are a couple scenarios to help understand some general trends. Let’s say for example, we have a Duramax which has been built with a large set of compounds (S472 over an S500) making 1,400hp and it starts to spool around 2,500 RPM. It will be very lazy off the line with a stock converter (stalls +/- 1,600 RPM). If you tried to hold the brakes and spool up the turbo, the engine would be held about 1,000 RPM below where the turbos come alive, so the chargers would never fully light and build any boost. Once you let your foot off the brake and start to move, the RPM will slowly go up, and after a bit the turbos get the invitation and party starts. Having a too-low stall speed will result in a very slow 60’ time and a laggy truck with high EGTs when driving around town, because you won’t be in boost. However, by only changing the stall speed of the torque converter to a more suitable level, (around 3,000 RPM), the turbos will spool much quicker even under light throttle, the torque multiplication factor will go up further helping acceleration, and if you want to hold the brakes and do a boosted launch the chargers will quickly come alive, and you’ll be slammed into the back of your seat just like the millennium falcon jumping to light speed.

By comparison, let’s say you have a bone stock truck and install the same 3,000 RPM converter. As it turns out, you’ll also be disappointed with the results of a mis-matched combination. When you take off from a light, the engine will rev up much too quickly and be near redline before the truck starts moving. Driving around town would be a nightmare, and the engine will constantly be at a high RPM just to make the truck move. These are both extreme examples but still illustrate the need for a correct stall speed. If you’re like more truck owners and have a lightly modified truck with a drop-in turbo upgrade and tow every now and again, you could benefit from a triple disc converter with a stall speed slightly higher than stock, around 1,900-2,100. Even though they are offered for most applications, there are very few instances when a lower-than-stock stall speed converter is appropriate, and usually this is on an engine which turns very low RPM like a 12-valve Cummins with a stock turbo, which can spool almost off idle.

Extra Power Capacity

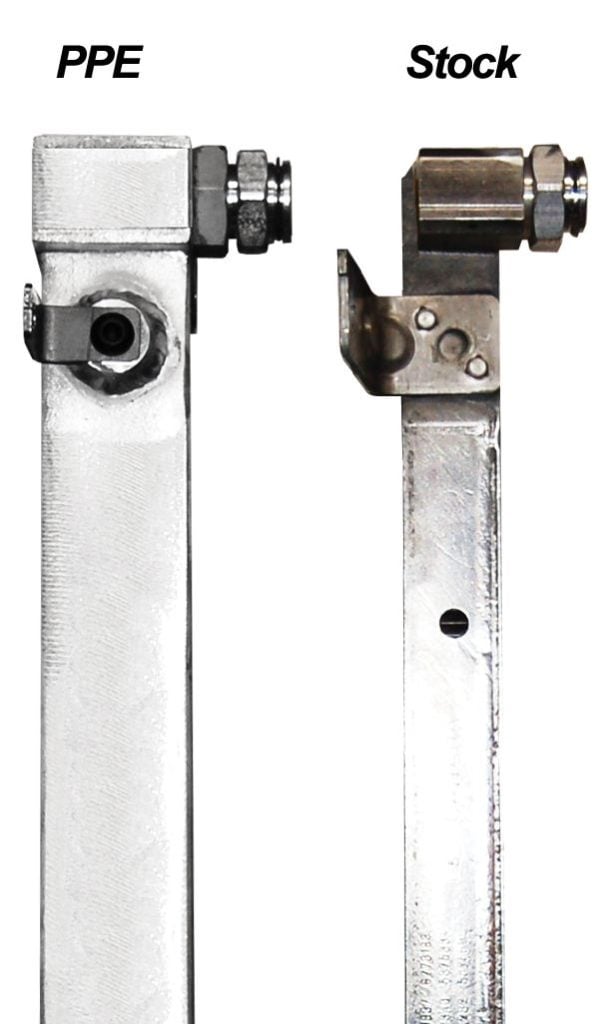

Once you’ve decided which torque converter is ideal for your transmission, there are still many more options you can choose from while building or upgrading your trans. With any automatic, there are three ways to increase the holding power of a clutch pack: more clamp load from higher fluid pressure, more friction surface area from additional clutch packs, and a clutch with a higher coefficient of friction. From the factory, transmissions are designed to be comfortable for the average driver. Smooth shifts are to be expected, but a smooth shift means the clutch packs are slipping while the gear change occurs, which combined with increased power leads to burnt clutches. By modifying the hydraulic control system with a shift kit, line pressure goes up and the duration of the shift event can be decreased, which will increase both clutch holding power and life expectancy as well as acceleration times simply by swapping out a few springs and check balls inside the transmission and modifying how quickly the shift happens.

Along with a shift kit and better converter, during a transmission rebuild, you can also change the type of friction material, in the same way there are different types of brake pads. A PPE stage four kit for the ’03 to ‘10 Ford 5r110 can help your clutches to stand up to almost double the power of stock. For most folks who have a bolt-on and tuned truck, a transmission built with a stronger converter, shift kit, and good clutch material will last a life time, but there is one more level you can take most transmissions to. Usually, any time a truck makes somewhere over the 800-horsepower mark, there is a risk of snapping or twisting the shafts inside the transmission. At this point, the factory shafts simply aren’t strong enough to cope with the massive torque of a diesel, so a billet shaft made from a stronger material is added to the build to keep you out of the shop and in the winners circle.

The last and perhaps simplest way to increase the reliability of an automatic transmission is to make it run cooler. The two most popular ways to accomplish this are to install a deeper transmission pan which holds more fluid and has more fins to help dissipate heat, and finally, install a larger transmission cooler which will pull more heat out of the fluid. Remember: a cool transmission is a happy transmission.

When to Shift

Outside of making hard-part changes to your transmission, one more way to make it better suit your overall build is making sure the shifts occur at the proper RPM for your engine. Shift too soon, and the turbos will fall out of their efficiency zone, and likely you’ll experience compressor surge and a loss of power. Shift too late, and you’ll still be going slower since the engine is revving higher than its peak power. Paired with a custom engine tune, a good TCM tune can optimize the shift points for your setup, making for a well rounded truck that downshifts when you want it, upshifts when it needs to, keeps the engine always under boost, and locks the converter at just the right time for maximum acceleration. In some extreme cases, a computer just won’t cut it anymore, so if you have a race truck, a full manual valve body can be added so it will shift exactly when you reach down and smack the shifter.

Do Your Research

If you look at the production numbers from the last 20 years, you’ll find the vast majority of diesel pickups left the assembly line with an automatic. In fact, when Ram discontinued the G56 manual for 2019, EVERY new diesel truck now comes with an automatic. They’re easy to drive, work great while towing, are simple to manufacture, and are generally very reliable. If you are into racing and high performance, an automatic can be made to shift quickly, plus, you can build one to hold insane amounts of horsepower and torque. I do admit, if you add up the costs, it does take a significant investment to bulletproof any automatic trans, regardless of what type of truck it belongs to. But hey, if you want to run a water park, then you’ll need to pay for some water. Just remember to research the ideal combination of parts and ask the experts in the field, because the right parts combo is what makes the difference between a daily driver and a driveway ornament.