One of the most frustrating things in the world can be heading out to your truck in the morning expecting it to fire right up and take you to work, only to find it wont start. Dead. Zilch. Nada. In a few short moments, your normally mundane commute has suddenly turned into a guessing game, and now you need to figure out if there’s a quick fix you can do to get back on the road or if you’ll have to call an Uber.

At its core, a diesel engine is a relatively simple machine; it only needs fuel and air to fire up, but common-rail diesel engines have a sophisticated control system with many small parts which all must work in concert to deliver exactly the right amount of fuel at the right time. If just one of those parts fail, it can take down the whole system, and it sometimes can be difficult to find exactly which part is at fault, especially if you’re running late to work. Today, we’re discussing ways to properly diagnose what is causing a diesel engine to not start, and we’re focusing specifically on the LB7 Duramax.

Batteries

The very first thing you need to determine when your truck won’t start is whether it cranks over or not, because a crank no-start condition is much different than a no-crank situation, and that’s where we’re gonna start our discussion today. The starting system on an LB7 Duramax is comprised of the batteries, battery cables, the starter (which includes a solenoid, DC motor, and a gear reduction) and the ignition switch on the truck that sends the signal to actuate the starter.

If your truck won’t crank over, the first thing we need to do is see if the batteries have voltage. A sign of a completely dead battery would be that no electrical components inside the truck turn on: no radio, no ding when the key is in the ignition, no lights on the dash, nothing at all. If this is the case, first check to see if the battery cables are disconnected or if maybe the lights were left on overnight. Generally, if the batteries are less than 2-3 years old, they shouldn’t be worn out, but something like a failing alternator can cause a battery to discharge. If you find that everything is connected but you still have no power to the truck, throw a battery charger or jumper cables on and get some voltage into the batteries. If the batteries are over 5 years old, chances are they need to be replaced. It’s also worth noting that you should always replace batteries as a pair, because if one is weaker than the other, it will kill your new battery much quicker.

Starter

If you’ve ruled out the batteries, the next thing to look for when your LB7 won’t crank over is the starter.

The best way to confirm if the starter is getting what it needs, is to measure for voltage at two different places: the starter solenoid signal wire and the main battery cable. If you have a multimeter or DVOM, set it to DC voltage and connect the black lead to a chassis ground and the red lead to the solenoid trigger wire on the starter, and have a helper turn the key to the crank position. If you see 12 volts when the key is turned, you know the ignition switch and wiring are working properly. Next you need to check to see if the main battery cable that attaches to the starter also has 12 volts, but it should have voltage in all key positions. If you do have voltage at both points but the engine won’t turn over, the starter is the culprit. If you’re in a pinch with a bad starter, an old-school trick is to gently tap the bottom of the starter with a hammer while someone tries to crank the engine, and sometimes you’ll get lucky, and the engine will crank up. While this is not a permanent fix, it might at least get you to the parts store so you can buy your replacement starter.

If you hear what sounds like a bag of hammers in a blender when you hit the key, you have a unique no-crank condition where either the starter gear or the ring gear on the flexplate is damaged. The starter is turning like it should, but it’s unable to properly engage and turn over the engine because several teeth on a gear are missing. If you hear this grinding noise, you’ll have to remove the starter and inspect the starter and the entire circumference of the flexplate by manually turning the engine over, but chances are you’ll find a spot or two where the teeth are missing from the flexplate. Unfortunately, this is a time-consuming repair because the transmission must come out to gain access to the flex plate. While this is a tough job, it’s a great opportunity to upgrade to an SFI certified flexplate.

The Engine Cranks, But Won’t Start

Once you’ve verified the electrical side of the truck is working properly and the engine cranks over at full speed when you hit the key, it’s time to move on to the fuel system. Except in cases of severe mechanical damage, healthy engines will have plenty of compression to ignite the fuel, so most crank no-start conditions come from issues with the fuel system.

Air Leaks

Sometimes a faulty fuel level sending unit can erroneously report how much fuel you have, but we’ll begin this section assuming you’ve already ruled out an empty fuel tank. For me, the first thing to check on an LB7 fuel system is the filter mounted to the passenger side valve cover. On top is a hand pump and a bleeder screw that lets you prime the fuel system and remove any air after replacing a fuel filter. Slightly crack the bleeder screw with a flat blade screwdriver, and push the primer pump a few times. If it takes a ton of pumping before you get any fuel, you have air in the suction side of the fuel system which is the cause of the engine not running, but the trick is to find out where air is introduced into the system. If your LB7 Duramax is stock, this can be a little tricky because the fuel system operates under vacuum from the injection pump, so you usually won’t be able to see evidence of fuel dripping.

There are several areas that can let air into the fuel lines, but the most common is the fuel filter head. There are several O-rings around the primer pump and the bleeder screw, and over time these O-rings can crack and let in air. The best fix is to replace everything with a filter head rebuild kit, and it’s a good insurance policy to also replace the plastic bleed screw with a billet aluminum one that won’t crack. After the filter head, the next likely culprits for air in the fuel lines on an LB7 are the rubber fuel hoses in the valley of the engine that connect to the CP3 injection pump, the fuel filter housing, the fuel injection control module, and the fuel pressure relief valve. These rubber lines get very brittle with age, and when they crack, air will be allowed to enter the system which will cause your no-start condition. Many of these rubber lines are molded to a specific shape and diameter, but OEM replacements are available that fit just like the factory parts. It goes without saying, it’s a good idea to replace ‘em all when you’re in there.

The fuel lines that run between the tank and the engine are mostly made from steel and rarely leak, but there are short sections made from flexible rubber which can collapse from suction and cause restrictions or even block fuel flow. Finally, the lines inside the fuel tank that connect to the pickup on the bottom of the tank can crack and let air into the fuel system as well, but those are much harder to track down. Also, don’t forget the obvious stuff: many owners don’t change their fuel filter regularly (it needs to be swapped about every 10,000 miles) and if it gets clogged, it can restrict fuel flow. Look for other environmental factors as well, like a drastic drop in air temperature. Diesel fuel can turn to a gel in extreme cold conditions, so if you suspect that’s happened to your truck, bring it inside the shop overnight to let it warm up, change the fuel filters, and see if that solves your problem.

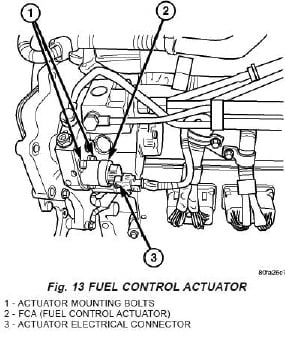

FCA/Regulator

If you can rule out air in the fuel system but the truck still won’t fire up, it’s time to get the scan tool out and monitor fuel rail pressure while cranking the engine. For an LB7 to fire up, it needs about 1,500psi of fuel pressure and about 2,500psi to idle, and if you don’t have that, there’s a few places to look. On the back of the CP3 injection pump is a small electric solenoid which controls how much fuel is allowed to enter the pump. People often refer to this as a pressure regulator, but its name is technically the Fuel Control Actuator. It receives pulse width modulated voltage from the PCM, and when the valve closes, no fuel can enter the CP3 and pressure drops, and when it is fully open, the CP3 will deliver its maximum pressure. One simple way to test if a failing FCA is causing a no-start condition is to unplug it. At zero volts the FCA defaults to wide open, which gives almost 26,000 psi of fuel pressure and the truck should fire right up. If this happens, simply replace the FCA and be on your way.

FPRV

If you’ve ruled out the FCA, there is another part of the fuel system can contribute to a lack of fuel pressure known as the FPRV or Fuel Pressure Relief Valve. This part is designed to be a blow off valve for the fuel system. Whenever you lift your foot and quickly transition from full power to idle, fuel demand suddenly drops, but it can take the CP3 a few moments to adjust to the lower demand of fuel. Normally this won’t cause any problems, but occasionally in the right conditions this can result in fuel pressure spiking, and the FPRV is there to prevent this from happening by bleeding off the excess pressure. It’s said however, that once the FPRV bypasses fuel a couple times, the valve can become stuck open, and when this occurs, you’re not going to build any rail pressure.

To narrow down your no-start condition to an FPRV, you can log commanded vs actual rail pressure and look for a low fuel pressure condition, but that symptom won’t necessarily point to the FPRV alone. A surefire way to confirm it’s the FPRV is to remove the hose coming from the valve, add a longer hose that runs into a clear container, and crank the truck over. If there is any fuel coming out of the valve while cranking, its stuck open and needs to be replaced. The only time the FPRV should be open is under extremely high fuel pressure which you won’t have while cranking. Once you’ve determined it’s the pressure relief valve, you’ve got a few options. New genuine Bosch FPRVs are available, so you could just replace it for about $150, or you could spend a few more dollars and replace the fuel junction block that contains the valve and a new rail pressure sensor. If your truck has been highly modified or sees competition use, you may consider a third option and eliminate the valve altogether.

When commanding higher than stock fuel pressure in a performance application, the FPRV may not allow you to build your desired fuel pressure even if its brand new, and in those cases, a race fuel valve is the answer. This gets rid of the relief valve altogether and ensures you will have plenty of fuel pressure to start and idle the engine, but it also eliminates the risk of dropping fuel pressure at wide open throttle when you need it most. The best part is, a race valve is also the most affordable option at only $40.

CP3 Injection Pump

If your truck still won’t start and you’ve ruled out all the small parts up until this point, then things are about to get more expensive, but before you go throwing money at a problem, it’s still best to properly diagnose the cause. A failing CP3 injection pump can absolutely cause a no-start condition, but there are a few ways to confirm it’s the pump before you spend $850 or more on a new one. One method is to disconnect the rubber hose that connects the low-pressure fuel return from the CP3 into the fuel lines and replace it with a clear section of hose that loops up so you can easily see it. While you have a helper crank over the engine, take a peek at the clear hose and look for air bubbles. If there is a stream of bubbles being generated in the fuel, chances are the CP3 is shot.

Injectors

No discussion of anything LB7 related will be complete without mentioning fuel injectors. They are known to be problematic and generally need to be replaced every 100,000 miles, and occasionally they can be bad enough to cause a no-start condition. A healthy injector will put most of the fuel into the combustion chamber where it belongs, but a worn-out injector will return most of its fuel back into the tank. The test to determine whether an injector is bad or not is done by accurately measuring the volume of fuel that gets returned.

The test does involve some more hoses and specialized fittings to attach to the injector return, along with a graduated cylinder so you can accurately measure fuel volume. Essentially, you will purge all the air from the system once the new hoses are hooked up, and then crank the engine over for exactly 15 seconds and measure how much fuel comes from the fuel injector return on each bank of the engine. If the injectors are healthy, there shouldn’t be much fuel at all, but the official measurement depends greatly on the temperature of the fuel. On average, there should be less than 20ml of fuel from each bank of 4 injectors for a 15 second cranking cycle, so if you see more than 20ml from one bank of the engine, there is at least one faulty injector on that side. You can further perform this test by measuring individual injectors, but if you have one or two out of spec, it’s just a smart move to replace them all at once. Yes, that’s expensive, but it will save you some headaches down the road since they’re all done.

Start Your Engine!

The bulk of most no-start conditions on an LB7 have to do with the fuel system, some with the starting system, and occasionally there will be trouble caused by other sensors like the camshaft position sensor, crankshaft position sensor, fuel injection control module, a faulty ECM, and more. Likely if there is an issue with any of those systems it will be accompanied by a DTC code that at least points you in the right direction which is helpful. Keeping an older LB7 on the road can be frustrating and rewarding at the same time, but the purpose of this article is to keep it from becoming too expensive. Nothing is worse than throwing brand new parts at an older truck on a hunch in might fix the problem, so by properly taking the time to think through the problem and diagnose the issue, you will only spend money on the parts you need.

just wanted to let u know thhis was the best info about a duramax engine that ive read. other write ups tell u to do somethng but this one tells u how and why. thanks so much.

This article really helped us track down a recalcitrant LB7 DuraMax vehicle.

All of the processes were explained well. A diagram of the system would have been nice.

I’m not complaining. This process of elimination saved us hours.

Thanks for your help it’s very nice to have a helping hand. When you don’t have any starting point When comes to diesels to a no start, no cranking no nothing.

You bet, if you have any questions, always feel free to send us an e-mail ([email protected]) or give a call to 888-99-DIESEL

I have a 2001 GMC Duramax and the other day it decided to just no start. It turns over great but no start. Put squirt a little gas in the turbo horn and nothing. And the only thing that comes up is a ccm with a yellow light. It’s getting fuel and no air in the lines. Any help would be appreciated

2004 Duramax asks for 41 mpa to start it gets to 33 mpa according to your specs 33 should be enough to start I figured it needs at least 4500 psi to start

My 01 6.6 Duramax won’t start. I was turning it over last week and I got the starter hot enough to burn the solenoid. I replaced the starter and now it turns over but won’t start is it possible that I burned something else up

Did a complete engine change due to a broken crank…. the replacement engine had a water in the disel issue..I swapped part after part…. finally found your thread….most excellent explanations and remediation tips with out your insights…. might have been scary wish I had found you earlier but….. better later than broker… awesome 👍 keep it coming… Ty Ty

Any info on cranks no-start with a code for crankshaft code P0335? Changed the crankshaft sensor and still no start.

My truck will start if it’s warm out but not in the cold any ideas