Written By: L.T. Tolman

Talk with any diesel guy about the Duramax, and nine times out of ten, the name Allison will also come up. While the exact numbers are unclear, its estimated only about 3% of Duramax trucks came equipped with a manual transmission, the ZF 6-speed. This means the other 97% of the (more than) two million Duramax’s produced came attached to the Allison A1000 automatic transmission, a version of which is still used today. Since Allison primarily manufactures transmissions for heavy duty trucks and buses, it was a huge deal when GM started sending trucks off the assembly line equipped with the A1000. They have a lot of high-tech features, and if you keep your truck stock, the Allison will last for hundreds of thousands of miles. But if you like your coffee black, your steak rare, and your tires smoking, then you’re going to have to put some dollars into the transmission to make it survive behind the mighty Duramax. Today we’ll go over some of the common issues you’ll run into when sending more power through an Allison transmission.

5-speed Allison: ’01 to ‘05

The Allison found behind the LB7 and LLY (2001 to 2005) is a 5-speed unit. Forward ratios include 3.094:1 in first gear, 1:1 in 4th, and 0.711:1 in 5th giving a great blend between acceleration and cruising RPM. It’s generally accepted the 5-speed A1000 will handle somewhere in the ballpark of an extra 90 horsepower over stock, which in the grand scheme of things isn’t that much. Luckily, when you overpower an Allison, there won’t be an explosion of parts, instead you’ll just experience a slipping clutch pack. Sometimes it’s so slight the driver doesn’t notice, but since the TCM controlling it is constantly monitoring input and output speed, it can immediately tell if a clutch pack is slipping. When that happens, the truck will enter limp mode. Essentially the transmission is saying something is wrong, and it’s trying to protect itself, so it will lock into one forward gear, allowing you to limp the truck home and make repairs. You can clear the code with a scan tool, or just shut the truck off, re-start it, the TCM will reset, and you can continue your journey. Just remember, the more often you slip or limp your trans, the quicker it’s going to wear out the clutches and need an overhaul.

6-speed Allison: ’06 to ‘10

With the introduction of the LBZ Duramax in 2006, the Allison behind it got an upgrade as well, gaining an additional forward gear. 1st through 5th share the same ratios with the earlier 5-speed, but 6th gear (or double overdrive) comes in at 0.61:1 which makes for low RPM while cruising down the interstate and improved fuel mileage. Several other internal modifications have increased the strength, and generally a healthy 6-speed Allison can hold about 130 horsepower over stock. This sounds like good news, but keep in mind the LBZ and LMM found in front of the first 6-speeds are more powerful, so you can still experience limp mode with a basic tuned truck.

The torque converter is another weakness of both the 5 and 6-speed Allison. The TCC lockup clutch uses a single-sided friction element, and a tuned Duramax can easily overcome its holding power. The most common time you’ll slip a converter clutch is at highway speed in 5th or 6th gear, when rolling into the throttle near peak torque. If you hear a groaning noise or feel a slight vibration accompanied by a quick jump in engine RPM, back your right foot off the go pedal, or just downshift to get the engine away from peak torque.

6-speed Allison: ’11 to ‘16

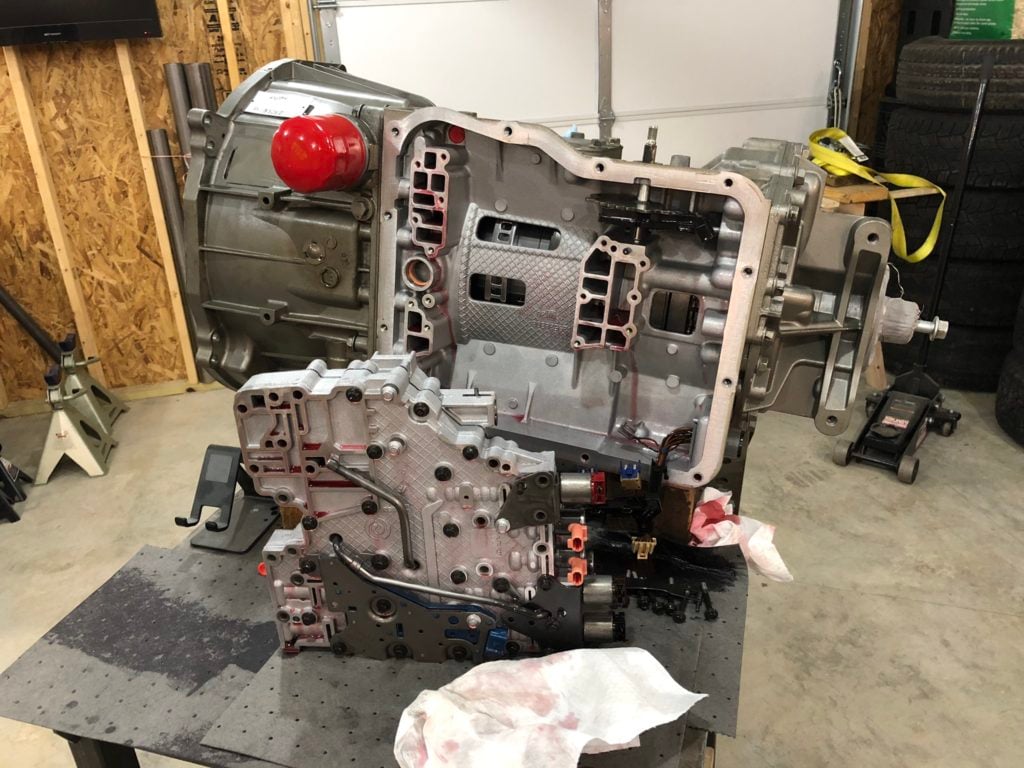

When the LML came along, it was making much more torque than its predecessors, so of course the Allison needed some upgrades as well. Once again, minor modifications were made inside to increase its capacity, and the torque converter now featured a dual-sided single friction element. The valve body got some hydraulic tweaks, and now the TCM had full control over line pressure, and this version of the transmission is capable of roughly 550 rwhp, making the LML Allison one of the toughest to date. But regardless of which version you start with, the A1000 will need attention at some point.

Build on a Budget

Every time you limp your Allison, it’s a subtle reminder you need to turn down the power or beef up the transmission, and since the GM platform is so popular, there are options for every power level and budget. The most affordable option involves removing the valve body and installing a shift kit. This modifies the trim valves, making for crisper and quicker shifts, and helps improve the holding capacity of the C2 and C3 clutches. While this can help get you by in a pinch on a low power tune, a shift kit only addresses one of several areas that need attention.

If you need to take it a step further, an ATS Co-Pilot can do the trick. It will raise the failure threshold of a stock trans by an additional 280lb.ft. over stock. This is accomplished by taking control of the valve body, raising line pressure to about 230 psi, and locking the converter clutch much sooner than stock. This will give the average bolt-on guy a durable and long-lasting Allison that will hold up to towing, daily driving, and the occasional race. Once you’re ready to move on to the next level, you’ll have to make some changes to the hard parts inside the transmission. These budget friendly mods will work great on a low mile or healthy trans, but if you’re starting with a higher mileage or worn out Allison that’s been slipped a lot, it doesn’t make much sense to do these simple changes, since the clutches are already compromised. At this point, it’s time to bite the bullet, yank that trans out, and start with a clean sheet of paper.

Serious Upgrades

There are three ways you can increase the holding power of any automatic transmission; raise the hydraulic pressure (like with the budget mods), increase the surface area of a clutch pack (add more discs), and increase the friction coefficient of the clutch material. If simple hydraulic mods are no longer enough, it’s time to address the other two options, clutch surface area and friction material. If you’re a serious DIY’er and up for a challenge, then a PPE Stage 5 transmission kit can add significant capacity to your transmission for a reasonable investment. By increasing the number of clutches in the C1 through C4 packs, the Stage 5 kit can handle up to 1,200hp and 1,800 pounds of torque. However, if you want to achieve that number, you’ll need a few other parts to make the rest of the transmission live. Usually anything more than 750hp will require a billet input and output shaft, and much over 1,000 will require a billet intermediate shaft, planetary upgrades, and more.

Converter Therapy

Once you have the inside of the transmission built to suit your power level, your job is still not done. Now, the torque converter needs to be addressed, and there are several options you need to understand before you order a replacement. While there are several single-disc converters out there, those only should be used on a stock power level truck (ask me how I know). A triple-disc lockup unit will be required for anything over 500hp, and by having 3x the clutch surface as a stock converter, you can be sure it won’t slip when locked, so it will put all the torque of the Duramax down to the ground where it belongs. You can also select several different stall speeds, both lower and higher than stock. Bigger turbos require a higher stall-speed converter, which will compliment the turbo and result in quicker spool-up. While you can get a slightly less expensive triple disc converter with a cast stator, if you ever do a boosted launch, brake stall, or a lot of burnouts, then you will need to upgrade to a billet stator, as the cast one will fail, and damage more parts on its way out. The PPE heavy duty converter is the best of both worlds, and features a billet front cover, a billet stator, and triple clutch discs for unbeatable performance in any condition.

Supporting Mods

If you’re building an Allison to handle extreme power, there are a few more odds and ends needed to complete the package deal. You should install a billet flex plate to avoid cracking the stock stamped steel plate, and since the pump will be producing more pressure, it’s wise to upgrade the transmission cooler lines to a hydraulic style hose, eliminating the notoriously leaky stock lines . Since a built trans and looser converter will generate more heat, a larger transmission cooler will keep the fluid temperatures in check, and finally a deeper pan will hold more fluid and help keep high temperatures at bay.

If chasing parts and assembling a trans isn’t your idea of weekend fun, there are plenty of crate transmissions available for you to swap in place of your failing unit and get you back on the road in a hurry. Merchant Automotive is well known as an Allison expert, and their Pro Series transmissions are great for trucks that have larger injectors and compound turbos and need some serious holding power. All the hard work is done for you, and you get a transmission shipped complete with everything needed to complete the installation, even down to 24 quarts of fluid, and best of all, you get a two-year warranty.

You wouldn’t install a larger turbo or injectors and not adjust your engine tune, and the same principal holds true for the transmission. Since you select your torque converter based on your turbo size and what RPM it spools, it can be beneficial to also have the TCM calibration updated to optimize the shift points and torque converter lockup schedule, keeping your engine in its ideal RPM range. You can even adjust the amount of torque management applied during each gear change for optimum performance and transmission life. A good tuner like Calibrated Power can get your TCM and ECM tuned and optimized to work together as a comprehensive package with your specific mods, which can make the difference between an unbearable truck, and a high-powered rig that’s a pleasure to drive every day.

Any way you want it

I’ve always been an advocate of learning as much as you can about building your truck, and this especially applies to making parts selections for a transmission build. Luckily for us bowtie guys, there are more options to build an Allison A1000 than any other diesel automatic. When the proper parts combination is selected, one transmission can work in a race truck, tow rig, and of course the daily driver. It was best summed up by Socrates when he said, “how fast do you wanna go, how much weight do you wanna tow, and how much money do you want to blow?”