Written By: Lawrence “LT” Tolman

You might’ve heard that age-old adage about beginning with the end in mind, but what does that really mean? Let’s say you want to get to a certain destination, maybe the south coast of Florida. You could start your journey with the basic knowledge that your goal is south and east of your current position and just aimlessly drive in that general direction until you hit the water. You don’t have to be a rocket scientist to understand the likelihood of reaching your destination without some planning, a map, or GPS is pretty slim, and likely you’ll end up in New Hampshire or something. A better idea would be to enter an address into your favorite GPS app, and it will tell you the most direct way to reach your destination with very little wasted effort. Our passion is building trucks, not taking blind road trips, so what does this analogy have to do with building a diesel? It’s all about making a plan, having a realistic goal, and following very specific steps to reach your goal without wasting time, money, hurting your engine, or doing things twice. Here’s what I mean:

Before you start a new build, you should have a solid idea where you want to ultimately end up, whether your goal is to have a tow rig, a hot daily driver, or a race only truck. Depending on what parts you purchase, you can either make forward progress along the path you set out on, or if you get a little trigger happy and ignore the plan, you can buy the wrong parts and make several steps backward. Often, many of the parts you will add to your build will come in many different sizes, and it can be natural to think that the largest will be the best and will make the most power. While the biggest injector or turbocharger certainly has the capacity to make more horsepower than a smaller version, what impact will that have on the rest of the build? For a hypothetical build, lets consider a 5.9 Common Rail Cummins, with an end goal of 800 horsepower at the wheels, to be used as a hot street and weekend play toy.

Fuel the Fire

If you want more power from your diesel engine, the first thing you’ll need is more fuel. On a stock truck this is accomplished with a tune. By telling the ECM to leave the injectors open for a longer amount of time, more fuel is allowed to enter the combustion chamber. This is OK for a little more power over stock, but once you push an injector to the limit, its pulsewidth (or on-time, measured in microseconds or μs) becomes so long, the combustion event is no longer happening in the bowl of the piston when it’s near top-dead center. Without diving too deep into a technical discussion, a longer pulsewidth means the flame front is “chasing” the piston down the bore, which puts more heat onto the weaker outside edges of the piston and is a much less efficient way to make power. In simplest terms, keeping a small injector open too long is bad for your pistons, so to make more power safely, you need to install larger nozzles or injectors which can deliver more fuel in less time. So you should just go out and buy some 250% overs for your stock turbo 5.9 CR and hit the track, right? That’s a negative ghost rider.

Just as there are issues running an injector that’s too small, running an injector that is too big can also lead to issues, and possibly catastrophic failure. First of all, to make a larger injector idle and run correctly at part throttle, the pulsewidth (μs) will have to be cut down a ton, which can give poor fuel atomization, a hazy idle, and poor partial throttle response. Furthermore, at wide-open throttle your EGTs will go through the roof if you don’t have enough air coming from the turbocharger especially in towing conditions, not to mention your fuel mileage will go out the window. A 250% over stock injector on a 5.9 Cummins has an ideal power range somewhere between 900 to 1,600 horsepower, so if your end goal is only 800, then realistically you only need an 80% larger than stock injector. To get the correct amount of fuel into the engine, you could run some BD-Power Stage 4 180hp injectors which flow 93% more than stock. These would allow you to meet your power goal without being too big to cause drivability issues.

While the injectors are primarily responsible for CREATING horsepower, both the lift and high-pressure injection pumps also need to be scaled up to SUPPORT the increased fuel demand of the larger injectors. For our 800hp 5.9 example, the stock CP3 won’t be adequate, so you have a couple choices. Either you can add an additional CP3 with a dual pump kit which will support about a thousand horsepower with two stock pumps, or you can upgrade to a single “stroker” pump which has more capacity than stock. A Fleece Powerflow 750 is a 10mm pump which is rated at 750-wheel horsepower, or the next step up would be 12mm pump which can support nearly 1,000 by itself. You can go a little larger on the injection pump side of things without as many negative side effects, but keep it reasonable. While a pair of 14mm pumps could support around 2,500hp, you’re only going to be using a fraction of the available capacity, you will be raising the temperature of the fuel excessively and wasting a tremendous amount of money. With the high-pressure fuel taken care of, the next issue is the lift pump, and to support 800hp you’ll need a pump that move 165 gallons per hour (up to 900hp capacity) of fuel up to the inlet of the CP3’s, and a FASS Titanium Signature Series is just the ticket. Plus, the added filtration and water separation is a great insurance policy which will keep your new (expensive) injectors and CP3 nice and clean.

REST STOP #1: It’s worth noting there is an ideal sequence and order install your modifications. Still working with the 800hp goal on a 5.9 CR Cummins, the total cost of that caliber of build will no doubt be close to the cost of purchasing another truck, so it can take some time to plan and save for the big purchases. While a 180hp injector might be what you need, it might take a couple years to save up enough money for the built engine, big turbos, built trans, injection pump, and other drivetrain upgrades, so you may be tempted to throw in the injectors while you wait for the rest of the parts to arrive. For the same reasons discussed earlier, it doesn’t make a lot of sense to install a set of big injectors with a stock turbo for an extended period of time, since it can’t provide enough air to burn all the fuel being fed into the engine. It makes more sense to purchase the parts one at a time and stick ‘em on the shelf and install everything all at once. I do understand it’s easy to get impatient running around with a mildly tuned truck, but in the long run it’s a smart move to make for your truck’s longevity. If you do want to make some upgrades, a smarter move would be to upgrade some smaller items first, like the lift pump, head studs, valve springs, and the air handling system first.

With a Bigger Hair Dryer

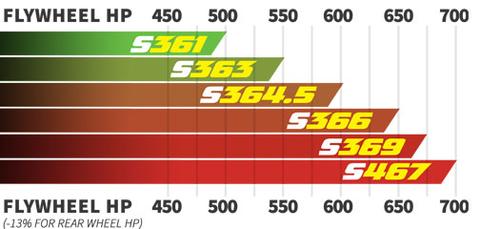

Just like with the fuel system, the air system is an important upgrade to a diesel truck when you’re chasing a big power number, but also just like with the fuel system, there is such a thing as too big of a turbo. If you ask 10 different people what the ideal size turbo is, you’ll get 10 different answers, since everyone’s opinion of what’s drivable and what spools quick is different, so we’ll speak in general terms. Keeping with the same 800hp example, it’s a fact the stock turbo won’t come close to that number by itself, regardless of how much fuel you push through it. The turbine and exhaust housing are simply too small, and the harder you push it with fuel, the more exhaust back pressure you’ll have, along with higher EGTs (DANGER WILL ROBINSON!). You could do a second-gen swap and install an S475 with the thought that its extra airflow will come in handy “just in case” you want to go further than 800, since a 475 can support almost 1,000hp by itself. In the real world, the 475 as a single will be very laggy on the street, especially with stock fuel. Again, everyone’s opinion of spool up and drivability is different, but why give up low RPM boost and torque if you don’t have to? At 800hp, a single S467 or S468 will be right in its sweet spot and will have much better street manners than a single 475. A compound turbo kit can also be sized too large, but the benefits of compound boost give you a much broader window to operate in. Adding an 80mm charger on top of the stock HE351 with an ATS Aurora Plus 7500 kit will make a 5.9 spool just like stock, but the added airflow up top will support tons of power, which is why I am a firm believer in compounds for any truck that spends time the street.

REST STOP #2: We’ve been discussing the air and fuel systems as stand-alone components, but the truth is both sides need to be addressed to balance everything together. You can think of it just like in high-school algebra class: if you add something to the fuel side of the equation, you’ll also need to make adjustments to the air side of the equation to keep things in balance. A larger turbocharger needs more fuel to spool, and larger injectors need more air to keep the combustion temps under control. It’s a symbiotic relationship, and that also extends to the rest of the powertrain as well.

The Rest of the Build

Once you have the air and fuel system sorted out, a lot of the hard work and planning is done, but you’ve just barely crossed the Florida state line. There are several other parts of the drivetrain that still need to be strengthened up, and careful parts selection is critical here as well. The torque converter you select will need a stall speed that matches what RPM the turbos spool at; too tight and your turbo will take ages to light, or if you go too loose (high stall speed) your engine will be out of its power band before your truck starts accelerating. The final drive will need a gear ratio that meets your tire size, and mile-per-hour goals, your exhaust needs to be the proper diameter, and there are about a dozen other smaller items to choose, like head studs, vibration dampener, flex plate, transmission shafts clutch material and more. When you consider and budget for every item that needs to be changed to meet a horsepower goal, the final dollar amount might surprise you. But, it’s better to know ahead of time what the final cost will be and adjust your final goals accordingly. And if you get stuck and need help making choices on what parts to select, or even want to discuss what a reasonable horsepower goal is, feel free to call in the backup, and give the guys at Diesel Power Products a call. They have a tremendous amount of experience with diesel trucks and will be happy to help you figure out what direction to take your build and recommend a parts combination to best suit your goals.

Patience is a Virtue

I will admit, the hardest part of building a truck is having realistic goals, and the second hardest is waiting for the parts to arrive. Sure, everyone wants to hit that magic 1,000 horsepower number, but is it worth it? Can you afford it? And do you need it? Or are you just chasing a number that sounds cool so you can tell your friends you have a thousand horsepower rig. And while we used an 800 horsepower 5.9 Cummins as an example for this discussion, the principal of balancing components can be applied to any type of build, whether you’re after 500 or plenty more . Just remember to stick to your plan and select parts that aren’t too big or too small, and you’ll be in Key West in no time. The last thing you want is for your build to go sideways and wind up with a connecting rod hanging outside of your block somewhere on the side of the road in New Hampshire.

I’ll leave you with this parting thought: if this is your first time building a high-power truck that will spend a lot of time on the street, it might be worth considering the limits of your stock pistons and rods and use that as a target HP goal. While a six to seven hundred horsepower engine doesn’t sound as cool or impressive as a thousand, it is much more affordable, and cost is the final (and arguably the most important) variable in the equation that needs to be balanced. Besides, you can always go nuts the second time around…

So I have a 2011 duramax and I did a cp3 conversation,fast lift pump,and 80%injectors. Are 80% injectors to big for stock turbo or is it tunable?

Hi there, thanks for the inquiry. The short answer is that yes, you need to go with a larger turbo. While piezo injectors are very tunable in terms of controlling their duration and injection event timing, the fact of the matter is that even if you narrow the injection event to limit fueling, and get the correct amount of advancement to avoid excessive fuel in the chamber before adequate compression occurs, you’re still dumping a lot of fuel during each cycle compared to how much air is being fed into the cylinders. And honestly, once you still limit the fueling as much as you can, the truck just won’t run properly due to the short injection event and lack of air. Presuming you have the injectors installed already, I’m sure you’re experiencing excessive smoke and EGT’s. With 80% over injectors, you’ve got massive potential for power, so really depends on how much you’re looking to make to properly size the turbo with it. There’s been plenty of trucks making 600 RWHP on stock injectors due to the design characteristics of piezo injectors compared to their preceding common rail injectors. You’d probably best be suited for an S467 which would also require a complete turbo installation kit, such as the below, to best match up to your fueling. Hope this gives you some direction, if you’ve got any other questions, feel free to respond back or give us a call: 888-99-DIESEL.

https://www.dieselpowerproducts.com/p-15670-fleece-s300-s400-turbo-installation-kit-11-16-66l-gm-duramax-lml.aspx

https://www.dieselpowerproducts.com/p-15852-fleece-performance-44-stainless-steel-t4-duramax-pedestal-01-16-66l-gm-duramax.aspx

https://www.dieselpowerproducts.com/p-12307-fleece-performance-s46783-turbocharger-03-cummins-01-duramax.aspx

I have a 2005 5.9 Cummins with a s366 and 30% over tips and a 33% over Industrial injection pump what can I expect for hp?

What tuning are you running, if any? We could get into serious particulars like transmission type, how its built, lift pump, gear ratio, tire size, etc., but if we at least know tuning, can give you a pretty good gut-check on where you should be sitting at. Also, in case you haven’t addressed it yet or aware, 2005 models (and only 2005), those trucks came from the factory with an intercooler featuring plastic end tanks. That with your S366 means bad news, so at the very least, swap it out with a factory intercooler from a 2003-2004.5 or 2006-2007, or while you’re at it, upgrade with an aftermarket that will flow and cool substantially better than stock.

Everyone only cares about street and race. I have a 2012 dodge Cummins dually. I tow really heavy. At 84,000 miles head gasket blew. At 94,000 miles I scattered the transmission all over the freeway. I did a ton of mods to try and make a 1 million mile motor. Allison transmission conversion mishimoto high flow intercooler, cold air intake, banks intake ram horn all the deletes even grid heater inside the intake. BD diesel rumble 3rd gen exhaust manifold and S364.4 turbo. GDP programming. Stock injectors. I just want it to tow good. My EGT’s go through the roof when lugging up an incline. I could melt the truck into a molten ball if I wanted too. Can you help me?

Hi there and thanks for the questions. The first question I’d have is how much weight are you regularly pulling? Secondly, you mention that when you’re lugging it up an incline, the EGT’s go through the roof. What kind of RPM’s are you running in these situations? I mean no disrespect when I say this, but all too often I hear people that are doing just that, trying to merely use the low end torque of the engine to climb grades, and doing so around 1400-1600RPM, and this is not a good idea. Your engine is essentially a pump, so if you want cold air to come in and hot air to get out, you need to turn the RPM’s up on the engine to evacuate those gasses at a faster rate. Next up to address the actual issues that may be going on with the truck or any upgrades. By chance have you checked for any boost leaks that could be occurring, such as around the intercooler boots? In order to do so properly, you’d need to pressurize the system. The simplest method I’ve seen to do this is by basically building a coffee can looking device that you can install over the face of the turbo using your existing hose coupler, then a valve which will allow you to pressurize with an air compressor and regulator. Next, you pressurize to about 20psi and either look for leaks, use a smoke machine, or just spray soapy water on all of your couplers. This will simulate a truck ender load, but without it even running. Next, have you questioned GDP on the tuning, potentially sending them any data logs so they can see if maybe you’re running too high or too low of rail pressure in these instances? Next, have you tested your injectors? Potentially, if they have an excessive return rate, they’re not properly atomizing the fuel in the combustion chamber, creating more heat than power. Also, what gears are you running? With it being a dually and you towing heavy, you’d want at least 4.10 gears paired with your Allison. And finally, depending on what kind of boost you’re seeing when pulling grades, it may be advantageous to actually drop to a slightly smaller turbo with a tighter exhaust housing, such as BD’s S363/76 that will aid in lower spool up. Boost=airflow, so we want to capitalize on that. And if none of these work, there are other more non-traditional methods of reducing EGT’s such as a cam (we like the Hamilton 188/220 as a drop-in) or even water-methanol injection. Good luck and let us know how we can help.

I have a 17 ram 2500. Running a s467 turbo, 100hp nozzles, bag of parts on the cp3, airdog 150, head studs, Randy’s stage 2 transmission, 3.42 gears with 35×12.50r20, running CCT tuning what would a rough estimate on HP and also should I be looking at getting a 10mm cp3.

Hey there, Kyle, thanks for the question. Let me start off with saying that I ALWAYS quote horsepower estimates relatively low because its no good thinking you’ve got a 700HP truck, then you slap your truck on a dyno, only to throw down 600 after you’ve told everybody for a year you have a 700HP truck. That said, I’m presuming you have a 68RFE trans that would have originally been rated at 350 to the flywheel. Also, I’m not as familiar with CCT’s tuning, so going to go off of some averages. Based upon what you currently have, I would say you’re conservatively between 550-600HP at the tires, but more than likely on the upper end of that. A few things off the top of my head that are limiting you would be the CP3 as you mentioned. The Fleece 10mm would be a great option:

https://www.dieselpowerproducts.com/fleece-cp3-injection-pump-67l-cummins

Another thing to think about are gears. You’re running relatively tall gears with 35’s and a good sized charger. By lowering the gear ratio, you’ll have more RPM, hence more airflow, in turn getting that turbo to light a little better, helping with streetability and just general driving manners, lower EGT’s, etc.

One last thing to consider would be sending in your injectors to be balanced. I’m not sure how many miles were on the injectors when you installed the nozzles, but having them balanced will help them run more smoothly, typically can also lower EGT’s, and get you a little bump in power.

Finally, with the addition of a 10mm pump, you’ll most likely be in that 650 range if you can properly load the dyno with the gearing and turbo you have. Again, thanks for the question and if you have any others, feel free to reach out.

Hi, thank you for your post. I`m still learning so please bare with me. Not a cummins related question but at least a Diesel Engine. I have a Ford Ranger 3.2 (PX1) which is a 5 cylinder 3.2L turbo diesel engine. I have done a few number of mods and have presently purchased a bigger turbo with 20% more flow over stock.

Mods:

Decat & Downpipe

Aluminum boost pipes

76mm Performance Exhaust

EGR Blank Plate / Delete

Catch Can

Water Methanol injection kit

ECU Remap (light tune)

Stock – 197hp (147kw) 490nm torque (flywheel)

Tune – 251 (187 kw) 688nm torque (flywheel)

I have kitted the vehicle with champing gear, steel replacement bumpers, etc. so it is very heavy! Hence I am looking at getting better performance while still being reliable and not blow up my engine in the process.

The turbo I have purchased is a Garret upgraded OEM turbo with 20% more flow and it would be capable of higher boost.

I will also be purchasing an aftermarket inter-cooler and air filter soon. I wont be going all out on the inter-cooler as i already have water meth injection.

Now the reason for my comment is about injectors, will my stock injector be sufficient?

I know there is a few options if I want more diesel going through the injector without staying open for too long as you have mentioned.

1 – Buying bigger injectors, or option number two which I think is better in my application.

2 – buying larger nozzles only.

The Vehicle has done 150 000 km before I started to do any mods so the injectors probably isn’t the best anymore, maybe i should do an injector service when replacing the nozzles if that is the option…

What do you recommend is the way forward making a decent amount of power safe and reliably?

Thanks,

Kenneth Norton Webber

Thanks for reading and the thorough question, and I must admit that you have the most highly modified 3.2L that I’ve come across or heard of so far! The factory injectors are a piezoelectric design which honestly have high potential, in general, for producing more power compared to their standard common rail counterparts. That said, I’m not personally aware of anyone, at least that we deal with, that manufacturers higher volume injectors or nozzles for your application. Because of this and the unfamiliarity, I can’t give you an honest answer of whether you’d need to modify. That said, based upon my knowledge of piezo injectors in general and your description of the turbo, its probable that your tuner could adjust fueling electronically to deliver an equal balance of fueling to match up to your additional airflow. As far as merely replacing the nozzles, while its possible to do so, with the amount of miles/kilometers on your truck, I wouldn’t recommend it. I’ve seen too many times when injectors are upgraded that have sufficient wear, and it only causes the bodies to wear out that much faster and then you have to replace them entirely again. Long story short, I’d recommend working with your tuner after the turbo is installed (which in of itself will require custom tuning) and see how your calibrations can be adjusted. If you reach a point where the additional fueling isn’t possible through tuning alone, then yes, I’d recommend upgrading the injectors, but the entire injector. You could also work with a company such as Dynomite Diesel that could build you a custom set of injectors matched to your particular application. Hope this information helps at least a little.

Hey josh so I added the 10mm cp3 and did Hamilton valve springs and extreme duty push rods. I don’t really want to Regear it so would dropping down to a 305/55R20 help instead of the 35’s.

If you’re wanting to increase the responsiveness of the truck, such as if you’d installed a larger turbo, then yes, going with smaller tires will do essentially the same thing as regearing. The question, though, is whether the 305/55R/20’s would be enough when going down from a 35″ as the 305’s are about 33.2″ but with that also comes a lighter weight. So, hard to answer your question precisely, but at the end of the day, any time you reduce tire size, the engine will definitely come alive faster. If you don’t mind dropping tire size, do it, but you can have the best of both worlds by keeping the 35’s and going with a lower gear ratio, such as a 4.10. One last thing to think about…..if you go down to the 33’s, those are still larger than a factory 265/70R/17 by about two inches, so if you’re running a big turbo, lets say a 66, you’ll still be experiencing a lot of lag compared to if you regear.

Well the factory size is a 275/70r18 which would come out to be the same height just wider. And I’m running a s467.7 with a 10mm cp3,100hp nozzles,air-dog 150,pusher intake horn,head studs, 103lb springs and extreme push rods and a Randy’s stage 2 68rfe. So that’s why I was asking if dropping from 35’s to a 305 with 3.42 gears if it would help it out or just stick with the 35’s. Just wondering if it would help some on egts fuel economy and lighting the turbo faster. Thank you.

Thanks for responding, Kyle, that gives more context as I was guessing at the factory tire size based upon a popular size. Anyways, you’re absolutely correct that the 305 will measure out the same diameter as your stock 275’s. That said, the S467.7 is definitely a big charger, but you’ve also got a benefit in having the six speed compared to older four speed 47 and 48RE’s. So yeah, the smaller tires will help and maybe that will be enough for you. Doing so will help reduce EGT’s because you’ll be running a higher RPM at any given speed, thus more airflow through the head as well as the faster response. By not having as large of a tire to spin, your fuel economy will also slightly increase. Personally, and I know there’s a lot of work involved, but not as bad as some would call out (or have a reputable shop do it), you’ll have better gains by going with lower gears and/or an upgraded cam, such as the Hamilton 188/220. For gears, to have a good middle ground, I’d go with a 4.10 or 4.30 as those stock 3.42’s are just a really tall gear for the size of your turbo. Then, back to the cam, the 188/220 is considered a “drop-in” and can make a HUGE difference in spool up and will pair up nicely with your 103 springs and push rods. At the end of the day, you either need more RPM to come on sooner to get airflow multiplying faster, or do it through a cam that can accomplish the same but in a different manner. If you’re able to, borrow a set of wheels and tires (or maybe you have your stockers still), and throw them on the truck and see how it performs. If that does the job, then you’re good to go. Otherwise, consider gears and/or a cam upgrade for a complete package, and keep the 35’s.

HI i am working on building up a truck that I drive daily but has a much power as that is safe to run. I don’t know, 700/800/900 hp? I have waisted some money when I first started but that was cause I originally just wanted to add stuff and didn’t know what I was doing or even wanting. I love a very quick spool up, I would say quickness is the most important aspect of having more power that i am interested in. then there is the part where it can keep pulling further and harder i have stealth 64 turbo, a cp4 10mm stroker, I’m only running a fass 150 lift pump, and i recently installed 5″ exhaust and have sdp high flow kit I’m getting ready to install.

can you guys recommend a path forward to a quick high, power daily driver. i want to be able to beat most of the cars driving on the street that people think they’re fast in. I’m not saying street race, I’m just talking about your friendly competition off a redlight when you are next to an equally competitive person and you can tell they want to see whos quicker just like you.

Terry, thanks for reaching out and sounds like the goals you have for your truck are similar to how we build many of our trucks, basically fast enough to beat about anything you’ll ever line up to on the street, but dependable and can still be used as a “truck.” Now, one thing you didn’t mention…..what truck do you have? You did say you’ve upgraded to a 10mm Stroker CP4, so by you saying its a “CP4” then it would be a 6.7L Powerstroke or 2011+ Duramax, or potentially a 2019-2020 Cummins. Then, off the top of my head, DuramaxTuner/Calibrated Power only builds a 64mm Stealth for a 2011+ Duramax out of those applications. And finally, SDP’s High Flow Kit is usually for an LML (2011-2016 Duramax). But anyways, all of that is guessing based on some of that info, so if you could let us know the vehicle that would help with some recommendations so we’re not guessing.

So I have a early 04 5.9 with 130% over injectors, 10mm cp3, airdog 165, built tranny and on3 compound gt45 over 63/67 he351 and MM3 tuning what HP #s do you think I’d be looking at

You’ve got plenty of fueling from the injectors, but your limiting factors currently are the injection pump and 165 lift pump. To the ground, I’d guess you’re around 750-800 RWHP, which is obviously still a ton of power and you’re at the level that all of the small details, like getting the tuning dialed in, can make all of the difference in the world.