Transmissions: they are often the most neglected part of your drivetrain. I don’t mean this in terms of maintenance, but rather in terms of the attention they receive when modifying your truck. If you have a fixed amount of money to spend, you’ll likely start with the fun parts that make your truck go faster and perform better. Things like a bigger turbocharger, larger injectors, wheels and tires, and even cosmetics all seem to take priority in the parts budget, until one day the transmission just decides its tired of the abuse and moves out leaving you with an expensive choice. The transmission is the one area which almost EVERY diesel truck needs improvement in, and it also happens to be one of the more expensive parts to replace, and as such, is usually last on the list to get upgraded. Recently, we’ve covered the many ways to add power to a diesel engine, but now we need to discuss ways to get the power to the ground. So, the question is: how much power can I add before I need to work on the transmission?

Because the majority of diesel trucks come equipped with a slushbox, it makes sense to focus the majority of our conversation on the automatics, and today we’re starting with Dodge. Chrysler used a few different transmissions behind the Cummins, and for a long time they were all variants of the same three speed automatic design which had been used since the 70’s. The earliest 1st gens got the 3-speed 727, and then came the later A618 and 47RH which were mechanically controlled. In 1996 the 47RE was introduced which was electronically controlled and it’s production ran until about 2003. At the time, those were the strongest automatic transmissions used in Chrysler applications, but the sad reality was they weren’t quite strong enough. In spite of their best efforts, the 47RE had a hard time keeping up with the stock torque output of the 5.9 Cummins, especially if the truck was used for towing heavy loads, so the answer to the original question “how much power can I safely add” is pretty much none if you’ve got a 47RH or RE.

When Cummins introduced common-rail fuel injection in 2003, the torque output of the 5.9 was getting pretty high, and Chrysler knew they needed a stronger transmission to cope, so they made several updates to the now decades old design, and this time called it the 48RE. In Dodge transmission nomenclature the “4” means it’s a four-speed, the “8” is a relative torque rating on a scale of one to nine, the “R” stands for rear-drive design, and the “E” stands for electronic, so it’s easy to discern what the transmission is designed for based on its name. Anyhow, when the 48RE came around in 03, we were pleasantly surprised to find it was a lot stronger than any previous Dodge transmission. When found behind a stock Cummins, the 48 holds up very well, but once you add a programmer and a heavy right foot, the limits of the new trans can be found easily. Really the question we need to be asking is what do I need to do to my Dodge transmission to make it hold more power? There are a couple different options as usual, and the process starts with the transmission coming out of the truck, throwing out a lot of stock parts, and performing a full rebuild. While that sounds complicated and expensive (which it is) it’s the one way you can ensure your dodge automatic can hold up to a lot more power.

What’s Going on In There Anyway

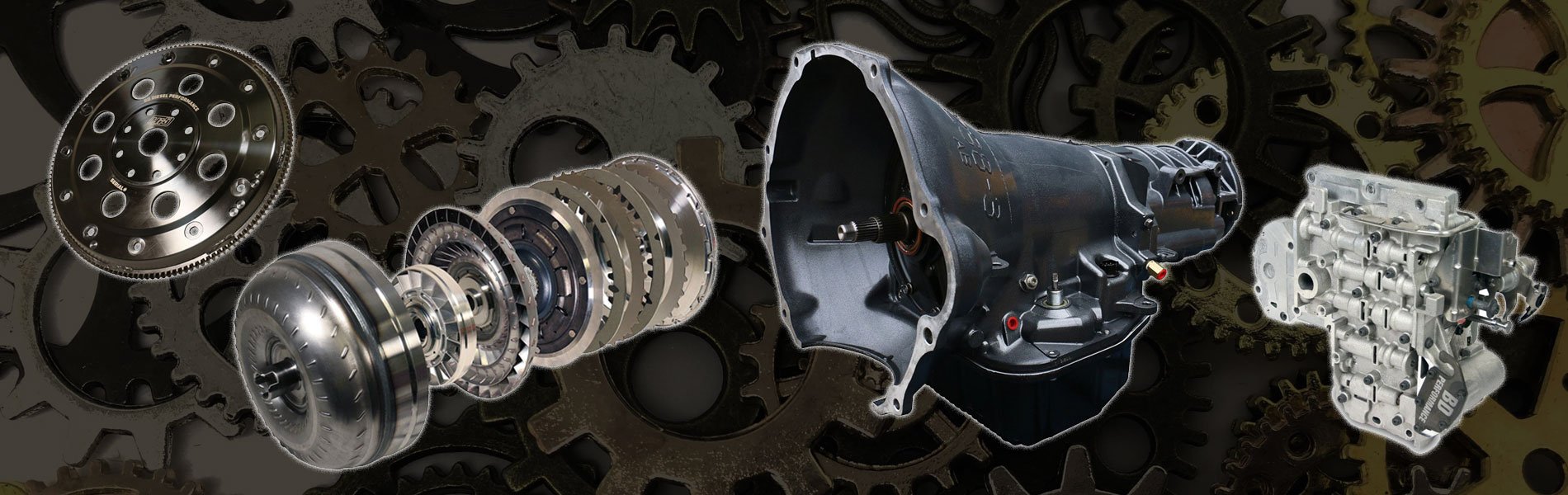

Every automatic transmission is comprised of several small rotating drums and gearsets with multi-disc clutches inside and is controlled by a valvebody which uses hydraulic pressure to engage and disengage various combinations of clutches to give different gear ratios. In order for a transmission to put all the power being fed into it to the ground, one of the first things you’ll need is a clutch pack which won’t slip under torque load, and there are three ways you can increase the holding capacity of a clutch pack, and the first method involves increasing the surface area by adding extra discs inside each drum. Since there is only so much room inside each drum, this is usually accomplished with thinner frictions and steels, removing some material from the piston and backing plate which applies the clutch, or a combination of both. Second you can increase the coefficient of friction of the clutch material with more aggressive compounds. Stock transmissions usually use a cellulose (paper) based clutch material which provides a nice smooth engagement and has a high tolerance to heat and slipping, but not the strongest grip. High performance materials for clutch discs can include Kevlar, graphite, carbon, and even ceramics, and while some may be grippier than others, the trade off is usually how much heat they tolerate, and how rough the engagement is. In a performance transmission, the trade-off is always between how smooth it shifts, and how much power it can hold. The final way to make a clutch pack hold more power is to increase the hydraulic pressure which clamps the clutches through modifications to the valvebody and pump with a shift kit. Again, the trade-off here is longevity and harshness, and if you get too carried away with fluid pressure, you can warp and bend the clutch discs or apply pistons.

Choosing Parts

While there is a lot of engineering and experience required to select parts for a transmission, a way to make the process a lot easier is to pick a rebuild kit which has all the parts selection taken care of, so all you have to do is find a power rating which matches your needs. Let’s say you have a 48RE and you need it to hold up to 850 horsepower and 1,500 pounds of torque yet still be usable on the street and for towing. For this application, a PPE Stage 4 Rebuild Kit fits the bill and comes with all the clutch related parts needed to beef up the transmission, including friction discs, stronger Kolene steels, pre-machined pressure plates, and of course all the gaskets and seals needed to finish up the job.

While an upgraded set of clutches is key to making an automatic trans hold more power than stock, if you want to get to that 850 number or use your truck to tow a lot, your build isn’t finished there. You’ll need a couple more things, and first on the list is where the fluid coupling happens. The stock torque converter has shortcomings in a few key areas which need to be addressed in a performance application: the stock stamped steel cover, the factory single disc lockup clutch, and the cast aluminum stator. Once the truck is moving, the lockup clutch can be engaged to provide a direct connection between the engine and trans, but the stock single disc clutch is a weak link and will slip under elevated torque levels. The stamped cover can warp and distort from heat and higher fluid pressure, and the cast stator inside the converter can fail under conditions like brake-stalling when trying to build boost for a launch.

A properly designed aftermarket torque converter can solve all these problems, and BD Diesel has a converter which will fit 1994 to 2007 four speed Chrysler transmissions, and will withstand up to 1,400 pounds of torque. First, the lockup clutch has three times the surface area as the stock version so there will be no issues with slippage. Second the cover is made from forged steel which is much stronger than stock, and finally the stator is made from billet aluminum which can withstand the harsh conditions of a boosted launch. While all those upgraded parts are required to make a torque converter hold more power, the stall speed is what can make or break the driving experience of the truck. Ideally, you’ll match the stall speed to your particular truck, taking into consideration the turbo size, gear ratio, truck weight, and intended usage like towing, racing, or just daily driving. Usually if you’re racing a lot and have a larger turbocharger, a higher RPM stall speed can make the turbo easier to spool and make the truck much quicker off the line. However, if you have a stock turbo which spools at idle and rarely hit the track, you’ll want a stock or even lower stall speed to transfer power quicker and get things moving right away. The best thing about the BD Diesel torque converter is you have your choice of stall speed to tailor your converter to work perfectly with your truck.

The clutch engagement of an aftermarket multi-disc converter can be a bit more abrupt than stock, and the shock load can easily twist and break the stock input shaft, and if (or when) it does, it will likely damage the torque converter and other components at the same time. Ideally, you’ll want to step up to a stronger version at the same time you install a triple disc converter. A Billet Input Shaft from ATS will transfer the torque from the engine into the transmission without breaking and rounds out the “major” upgrades needed on a 47/48. There are a few other goodies which can help strengthen up the transmission and shift quality, like the band lever and strut, accumulator pistons, and servo. A TCS Billet Combo is a nice add-on to any transmission build, and ensures positive and precise engagement of the band, and gives the servo more leverage for more holding power on the band. Finally, if you’re going through the effort of strengthening your transmission, you can’t forget about the external parts which help the trans survive, like a larger fluid cooler to keep the temps in check, a stronger flex plate which won’t crack, and deep transmission pan to hold extra fluid and help radiate heat to keep the transmission running cooler.

The honest truth is 99% of truck owners don’t feel comfortable selecting the parts required to build a high-power automatic transmission, much less be willing to assemble it on their own, so luckily there are tons of builders out there who offer “crate” transmissions which are assembled, tested, and will show up to your shop ready to bolt it. ATS Diesel Performance from Colorado is one of the better-known transmission shops in the game. They offer six different stages of transmissions which will work with any power combo you can serve up from mild to wild, and they all come with a five-year 500,000-mile warranty, which means this is the last transmission you’ll have to buy.

Six Speeds:

Most of the parts we’ve discussed apply to the earlier 47 and 48RE, but the same exact concepts can be applied to the later model 6-speed transmissions like 68RFE and AS69. Since there are so many moving parts inside, the 68 is certainly not a first time DIY trans build, and its best to leave it to the experts. Pre-assembled transmissions are available like the BD Diesel 68RFE Performance Transmission which works great for performance and towing applications, and it has all the right ingredients: more hydraulic clamping power, better clutch material, a triple disc converter, modified valve body, and a deep sump aluminum pan, all of which will transfer all your power to the wheels and not just slip your clutches.

Face the Facts

While Dodge and Ram owners are blessed with one of the most robust diesel engines in the game, sadly the automatic transmissions which backed them up were arguably the worst of the big three in stock condition. If you plan on adding power to your Cummins, you are going to have to build the transmission: there is no way around that fact. However, as long as you take the “build it once and build it right” approach, you’ll be set for life and your only worry will be how to keep the tread on your tires and how to keep the truck between the ditches.

I Owen a 2003 Dodge 3500 5.9 Cummings what is the ball figure to swap trans and have one of your trans installed . John from Ohio

Hi there, John. Are you looking for an installed price? We are located in Washington State, but we could recommend an installation facility in your area most likely. When you have time, please give us a call and we can discuss what transmission exactly will work best for how you use your truck and to account for any power adders you may have. Further, we need to determine how early of a model year your 2003 is, as the very early models have a 47RE before they fully transitioned over to the 48RE versions. So again, please give us a call at 888-993-4373.

I have an 03 Ram (later model, common rail) 3500, 5.9 Cummins HO, 6 spd manual (NV5600), SRW, 4wd. I have a Smarty Jr programmer installed at 60 HP increase. My wife and I have been full time RV’ers for over 11 yrs serving with a Christian volunteer construction ministry (CWCF). I tow a 12k, 40′ TT putting about 10-15k miles on a year, mostly hiway (ttl gross about 22,000 lbs). This is the trk/engine combo I prefer but my wife can’t push the clutch now since I had the trans rebuilt and put in a dual disc clutch (6 mo. ago) and she had a left knee replacement (16 mo. ago). So my question is, can the manual trans be pulled and an automatic installed? I have read your article regarding the improvements to the 48RE and it sounds like it is not enough as a stock trans for my needs. Can an upgraded 48RE or, preferably a 68RFE or AS69 be bolted up to this engine or is the rework for linkage, shifter, etc. just too much to be realistic?

I recently bought the MOPAR Steering Gear Upgrade Kit and Borgeson Steering Shaft from from you. I also have the upgraded (08 yr model) T-style steering linkage installed and have done some other work on the trk recently so I’d like to keep this trk if it is doable. Thanks for your time answering my questions about this.

Dave