Every system on a diesel truck is designed to be as strong and as durable as possible to withstand the rigors of towing and hauling, but when the engineers are deciding how strong to make certain parts, they only think within the parameters of a stock truck. It never crosses their mind that someone might add extra horsepower to the engine, throw on larger tires, or lift the suspension, so if you modify your truck outside of what it was designed to do, you should expect some parts will wear out before they normally would on an unmodified version. Today we’re going to be focusing on the front steering and suspension systems, and how you know when it’s time to replace or upgrade components that are failing and look at the best upgrades that solve common problems.

What Causes Front End Parts to Wear Out?

There are several reasons why your steering or suspension components will wear out, and the first and probably most obvious is normal wear and tear. In order to make the front wheels move up and down as you go over bumps and turn left and right to steer, a lot of moving parts are required. To keep those parts moving and reduce friction, rubber bushings and metal ball joints are used, but during their lifetime they will see hundreds of thousands of cycles back and forth, and as you can imagine, eventually they will wear out. In the old days, just about every moving part on your chassis would have a zerk so you could periodically add more grease into the joints to maintain lubrication and extend their life, but now a lot of manufacturers have left out the zerk and installed “lifetime” grease. The problem is that “lifetime” is a relative term, and often the grease the factory installed will dry out or the rubber boot will crack, and the grease slowly oozes out and you have no way to relubricate the parts. Even if you do have a way to add more grease, the moving parts of your front end can still wear out with normal use. Depending on how harsh the roads are and the percentage of highway versus in-town driving, the number of miles may vary, but an unmodified truck should get at least 100,000 miles out of the front suspension parts.

As you alter your suspension height or install larger tires with a deeper offset wheel, you also increase the amount of stress the steering and suspension parts are operating under, which can significantly reduce their lifespan, especially if they are factory parts with no provisions to add extra grease. Probably the worst offenders for breaking parts are the 12 or 14-inch-wide wheels with -44 or greater offset, since the deep spaced wheel requires so much leverage to move back and forth. If you must install a larger diameter tire but don’t want to wear parts out quite as quick, consider using a stock wheel, or an aftermarket one that has a little less offset than the SEMA wheels.

How Can I Tell If My Steering or Suspension Parts Are Worn Out?

Now that we know what causes your front-end parts to wear out, the next important question is how do you know when they need to be replaced? On one hand, you could just drive around until a wheel falls off the truck as a ball joint separates, but that’s not the smartest move, and there will be many warning signs that can let you know a part needs to be replaced well before your truck crashes into the ground. The first sign that something needs attention will be in how the truck tracks down the road. You should be able to drive down a straight section of road with very little input from the steering wheel, but if your truck wanders left and right and needs constant correction from the steering wheel to maintain a straight path, chances are a tie rod, pitman arm, drag link, or other part of your steering system is worn out. Next, take a look at the tires and check for irregular wear or cupping on the outside row of tread. If you see this, it’s a strong indicator you need to address something in the front end.

To further narrow down the culprit, you need to get your hands dirty. Start by raising the truck off the ground, support it with a jack stand, and wiggle the front tires back and forth. If you put your hands at the 3 o’clock and 9 o’clock position and feel free play or hear a clunking sound, this means it’s part of the steering system. Instead, if you place your hands at 12 o’clock and 6 o’clock and you get movement, that means it’s probably the ball joints, or if you get play in every direction, likely it’s the wheel bearings. One more way to narrow your problem down to a wheel bearing is by driving the truck and carefully listening. If you notice a growling or humming noise coming from the front that’s not normally present, this could point to a failing wheel bearing. Usually, the noise will get louder with speed, and not be affected by engine RPM or transmission gear, and if you turn the vehicle left and right and the noise changes, that’s a dead giveaway the wheel bearing is at fault.

After you’ve narrowed it down to steering or suspension, you can pinpoint the individual part at fault with some assistance. I like to have a helper quickly move the steering wheel back and forth by a couple inches, and crawl underneath the truck with a flashlight and look at the individual joints as they move, and usually if one is worn out, it will have a small amount of free play back and forth. Sometimes a little more leverage can help, so a 2×4 or a pry bay can be used to apply force to each individual joint to identify movement.

Are Stock Parts the Best Option?

Once you know which part needs to be replaced, you have a choice to make. Should you go with an OEM part or step up with an aftermarket upgrade? There are a few instances where stock replacement parts are truly the best option. Sometimes you can even use later model stock parts to upgrade an older truck, like using 4th gen Ram steering components on a 3rd gen, but there are also many instances where the aftermarket offers a much better and stronger option. Most of the upgrades we will discuss are oriented toward a truck that’s been modified in some way, and they have been designed to fight back against the added stress of larger tires, extreme use, or a lot more horsepower than stock, but you can also use these stronger aftermarket parts on a stock truck for the ultimate in longevity and durability.

The Last Set of Ball Joints You Need

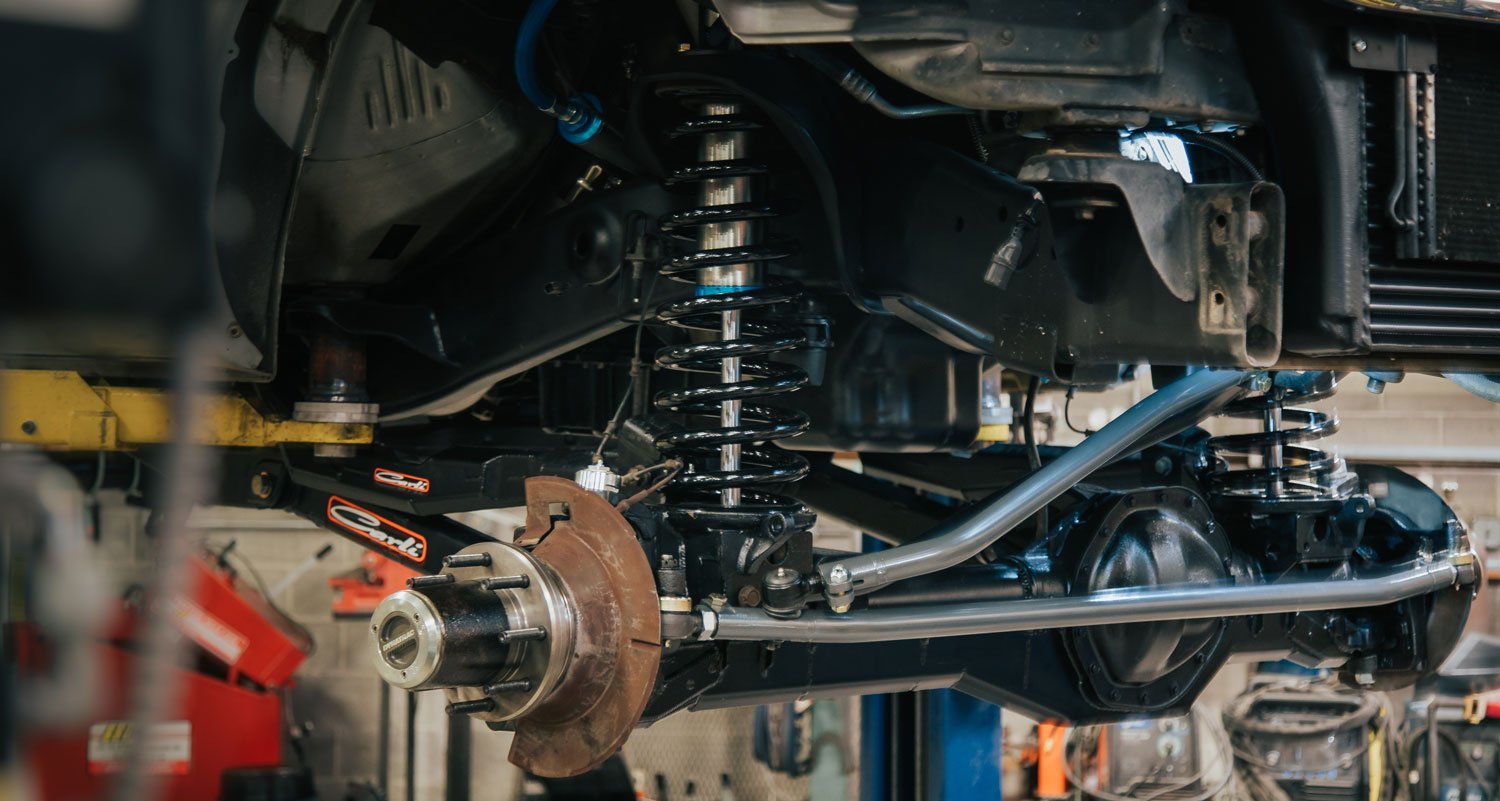

Every truck uses a pair of ball joints on each side to allow the steering knuckle to pivot left and right, and together they hold up the entire weight of the truck. Because of the stress they are operating under and how much work it takes to replace each one, I highly encourage an upgrade in the ball joint department. If you own a Ram or Ford with a solid front axle, the absolute best ball joints you can get are either Dynatrac Prosteer HD or Carli Extreme Duty. They have been designed to survive the harshest conditions, both on road or off, and will work with large tires, lots of horsepower, hydraulic assisted steering, or just about anything else you can throw at ‘em. Instead of using a plastic inner bearing like the factory joints, they have been engineered to use hardened metal and spherical bearings which last much longer.

Tie Rods and Center Link/Drag Link

Depending on which make of truck you own, your steering system may look a little different, but the major components are very similar. Tie rods attach to each steering knuckle, and some form of linkage will connect the tie rods to the steering gear box. One thing Duramax powered trucks are known for is bending or snapping stock tie rods. They are a wimpy design, and even at a stock power level with a stock tire size, a little too much throttle while 4wd is engaged can bend ‘em like a pretzel, and if you have wider tires installed, they’re about as effective as a wet noodle. Tie rod sleeves are an inexpensive solution that can increase strength and get you by in the short term, but the real fix for a GM truck is a pair of Kryptonite Death Grip Tie Rods. Sure, they cost a little more than the overseas replacements you can find at your favorite parts store, but they feature an inch and a quarter thick hexagonal steel body which can withstand up to 21,000lbs of force before failing instead of a measly 9,000lbs like the stock tie rods.

On a 2003 to 2008 Ram, a “Y” style of steering linkage was used. Overall, it was a fairly strong setup (especially when compared to Duramax tie rods) and it could handle a little larger than stock tire, but it did have an inherent issue which could contribute to some wobbly steering. Because the tie rod is not one solid piece connecting the two steering knuckles, a toe change will naturally occur as the suspension cycles up and down since the drag link connects to the passenger side knuckle, and the driver’s side tie rod connects to the drag link. In 2009 Ram changed their design to a “T” style where one solid tie rod is connected to each knuckle, and the drag link connects to the tie rod near the passenger side knuckle. This means there is no toe change as the suspension goes up and down which can tighten up the handling and road feel, and the tie rods are a little beefier than the early 3rd gen parts as well. Luckily, it’s easy to retrofit the later model “T” steering setup, and there are a few different kits to get the job done. If you are running stock or slightly upgraded tires, the factory Mopar steering upgrade kit will work for 2003 to 2012 Ram trucks, or if you need a lot more strength, Synergy Manufacturing is the way to go. Their Heavy-Duty Steering Kit operates with the same “T” style linkage as the 2008+ Ram, but their tie rods are 200% stronger than stock and they offer the strongest drag link on the market. To prevent the tie rod from twisting as the steering force is applied, Synergy designed their tie rods with a low misalignment spacer (aka a “wobble stopper”) which will prevent the dreaded shaking steering wheel which early Ram trucks are known for.

Wheel Bearings

If you’ve determined the wheel bearings are faulty on your truck, it’s a fairly easy job to swap in the replacement, since most modern trucks use a unit bearing style hub that simply bolts to the steering knuckle, so all you’ve got to do is remove the brakes, remove the axle shaft nut, and swap the bearing for another, but if you’ve got wider tires, you may be replacing stock unit bearings more than you’d like. To cope with the added stress on a Duramax powered truck, the best option for a lifetime unit bearing is from Kryptonite. They have designed the strongest possible unit bearing, and it uses a ball and taper style bearing surface for improved strength and reduced deflection. Kryptonite designed their unit bearings to operate on lifted truck with larger wheels and tires, but of course they will also work perfectly on a stock height truck as well. They come with all new wheel studs and an ABS sensor and will bolt right in place of your weaker factory unit bearings.

If you have a Ram or Ford, your truck will be equipped with a solid front axle, and while it uses a unit bearing from the factory, a smart investment in your front end is to convert to a tapered roller bearing with a Dynatrac Free Spin Kit. This conversion has two benefits which will improve the operation of your truck. First, by using a traditional tapered roller bearing and spindle design, you dramatically improve strength and reduce the cost of service in the future, since a pair of roller bearings and a seal will cost much less than an entire unit bearing assembly. The second benefit of a free spin kit is an increase in fuel efficiency and reliability, since you also get a manual locking hub that can be disengaged. This stops the front wheels from turning the differential and driveshaft when driving in 2wd. Less rotational drag means more fuel efficiency, and on top of that when you do need 4wd, the manual locking hubs offer much greater strength as well.

Steering Gear Box

Probably one of the strongest factory front end parts on your truck is the steering gear box, but there’s still room for improvement, especially if you have those pesky larger tires. Over time, the stock box can wear out internally which will cause slight free play in the steering wheel before the tires turn. The problem with many parts store replacements is they are remanufactured with fairly low tolerances, and often a generic reman unit will perform worse than a worn-out OEM steering box.

A Red-Head Extreme Duty steering box has been engineered to exacting dimensions, and each box undergoes a thorough measurement and inspection process to ensure only the best cores are used, and the internal components are specifically sized for each box to ensure the tightest possible steering feel with zero play. They are available with optional pressure ports for hydraulic assisted steering if you’ve got massive tires and spend a lot of time off road, but a Redhead box will work amazingly on a stock truck as well.

The End of Wimpy Parts

As owners modify their rigs and break stock parts, the need for stronger steering and suspension components has been made clear, and thankfully, the aftermarket has stepped up and filled that need with parts that will survive with big suspension lifts, wider tires, and extreme off-road use. Even if your truck is still stock, installing these upgraded parts will ensure you get the most from your money with parts that should outlast the rest of your truck, which sounds like a solid investment to me.

I have a 2005 Dodge Ram 2500 4×4,with steering wander.

I have changed steering box to a borgeson,and a steering box brace.replaces steering colum.end links,verious front end parts.

Any ideas?

Thx bruce

How do you know if your steering box is worn out or faulty?

The first thing to pay attention to is how much play is in your steering wheel, basically do you have to really turn the steering wheel before the truck actually turns. If so, then it could be the gearbox, but it could also be other loose front end components. With the truck running, have someone help you by watching the steering shaft and pitman arm while you turn the steering wheel. Try and tell if everything is moving together, or if when you’re turning the steering wheel, and the steering shaft is moving at the same rate, whether the pitman arm is delayed or even moving erratically. The latter would be very indicative of a worn gear box. If you’re over 100k miles especially and if you’re constantly fighting the steering wheel back and forth as you drive, its probably time for a new gear box.