The two most important systems required to keep any vehicle operating safely on the road are the steering and the brakes. One keeps you pointed in the direction you wish to travel, and the other allows you to bring your vehicle safely to a stop. Recently, we took a look at some of the shortcomings which can be found in the factory braking systems while using a truck near its maximum towing capacity, and not surprisingly there is certainly some room for improvement. One unique thing about your steering system is that it’s constantly being used whenever the truck is in motion. You won’t always be able to use your peak horsepower output when driving around town, or max out your braking capacity on a simple grocery run, but you are always using the steering system, regardless if you’re going five miles an hour or a hundred and five. Because of this, any small issue in the steering system will be readily apparent and very annoying for the driver.

When you pick up your truck from the dealer’s lot, all the systems of the powertrain will be balanced according to the parameters the truck was designed around. The horsepower, torque, and RPM range of the engine needs to match the gear ratios and strength of the transmission, and the diameter of the tires needs to match the gear ratio in the differential to compliment the engine and transmission. Similarly, the brakes need to be able to slow the weight of the truck and any potential cargo, and the suspension needs to have adequate load carrying capacity. Much like a Zen Buddha or a cat running along the top of a fence, everything has to be in balance.

Under normal circumstances, every part of the powertrain will work well together for many years to come. However, modifying a truck is as second nature as breathing for some drivers, and the thought of a stock truck is just heinous. If executed properly, a modified truck can have just as much (if not more) utility than its bone stock cousin if you remember to keep your trucks inner Buddha happy.

Balance Is Key

Let’s say for example you want to lift your truck and add some larger wheels and tires. That’s a very simple goal to achieve, but depending on how much bigger you want to go, you may need to make some additional adjustments to restore balance to your rig, like re-gearing, upgrading your brake pads and rotors, and what we’re focusing on today, a few key parts in the steering system.

On a GM IFS truck for example, the first parts in the steering you’ll need to address are the tie rods, since they are known to bend and break even with stock sized wheels and tires at the stock power levels. All it takes is a vigorous right foot with 4×4 engaged, and you can turn your stock tie rods into a pretzel, so stepping up to PPE Stage 3 tie rods will make a huge difference, and will work well in a stock or modified truck. Then, when you want to step things up a bit more and try out a boosted launch on the pavement, you should swap out the rest of the steering with a heavy-duty pitman and idler arm, and finally a straight center link to round out the most indestructible IFS front end imaginable.

By comparison, the steering parts on a 3rd gen Dodge Ram are physically much stronger, but there is some wonky geometry created by the stock “Y” style steering. There is a drag link which connects the pitman arm on the steering box to the right-side knuckle, and then a tie rod connects the left knuckle to the drag link. Because there is no solid link between the front wheels, the design allows for changes in toe-in to occur as the suspension cycles, and this can lead to the phenomenon known as “death wobble” which is as scary as it sounds. As you can expect, there are several ways to cure the problem, and one of the best is the Synergy Manufacturing Heavy Duty Steering Kit. This eliminates the poor geometry by converting to “T” style steering where a single tie rod connects each knuckle, and the drag link attaches to the tie rod. This small change to the drag link might seem inconsequential, but it eliminates the toe-change during suspension travel, and when combined with other tweaks like the built in “wobble-stoppers” which prevent axial rotation of the tie rod, you’ll be able to keep the tires pointed exactly where you want.

Final Piece of the Puzzle….

Whether you drive a brand-new lifted truck, or it’s got higher mileage and still rides on stock tires, you’ll want it to drive straight down the road. There’s no worse feeling than sawing back and forth on the steering wheel just to keep driving between the painted lines, and wandering steering is one of the main reasons why people start to upgrade and replace steering parts in their truck. Usually the first items to get replaced are the tie rods, pitman and idler arm, track bar, and even the steering shaft which connects the column to the gearbox. There will always be a bit of apprehension as you hop into your truck for the first time after rebuilding the steering, as you hope you sorted out all the wandering and play. More often than not, owners are frustrated to find there is still a small amount of play in the steering despite their best efforts, and they’re not completely satisfied with how the truck drives, and that’s because there is one last steering upgrade which often gets overlooked. The steering gear box is an important piece of the puzzle and it is a wearable item just like a tie rod or pitman arm: a worn-out steering box is the cause for sloppy steering on a lot of trucks. The simple solution is to swap it out for another, but that’s where your problems can start.

Any Old Part Will Do?

If you are unfamiliar with the term “remanufactured” here’s what it means: because certain parts are difficult or expensive for the aftermarket to make brand new, instead they’ll source old worn out parts (cores), and rebuild them to like-new condition to meet the demands of the market. In theory it’s no different than rebuilding a worn-out engine rather than buying a brand new one, but in practice, it can be hard to find a quality remanufactured steering box from a brick and mortar parts house. The tolerances for a precise part like a steering gearbox are often not checked or adjusted properly when reassembled, and furthermore, once the internal parts of a steering gear become worn or bent, the backlash might not be able to be set within an acceptable range. Yet somehow, they make it past any QC measures, and straight onto the shelves of your local parts store.

I personally have installed several reman steering gear boxes in different types of trucks, just to have the same or worse play as before the swap was made, and more than once I’ve found a reman gearbox to start leaking within a hundred miles of the install. Granted, most parts stores will warranty their product and swap out a defective steering box for another, but at that point you’re really just playing the odds and hoping the second or third reman box you install will eliminate your problems, even with a free replacement you still have to R&R the steering gear (AGAIN) which isn’t exactly a walk in the park.

You might be reading this and think “Why not just get a brand-new box from the dealership and be done with it?” While generally dealer parts are made to a stricter quality standard than a reman version, you do have a much higher price to pay, and for some applications you can’t even get a brand new steering gear box from the dealership in the first place.

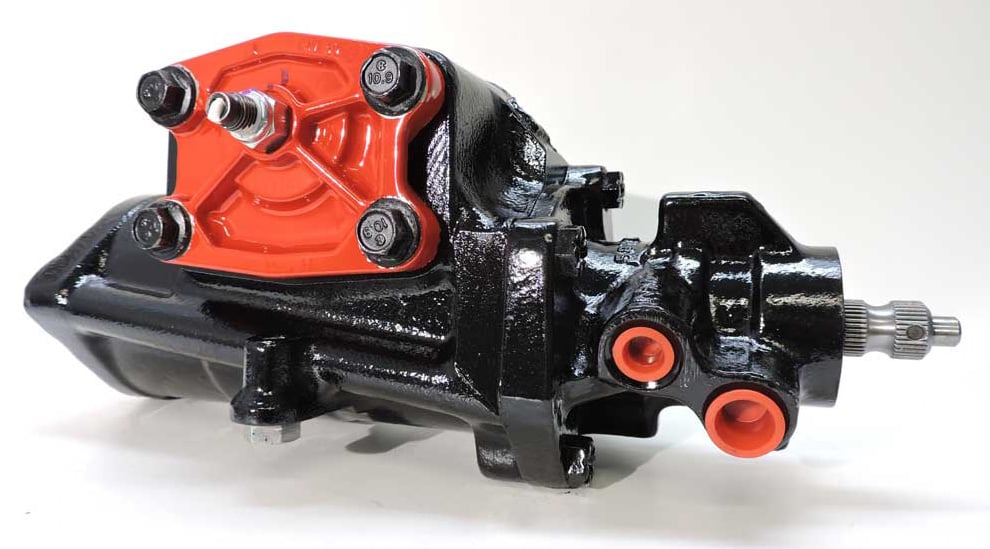

Red-Head Builds It Right

This is where specialty rebuilders come into play, to fill the void in the market between overpriced OE parts and sub-par reman versions with high-quality re-engineered steering boxes. RedHead Steering Gears is one such outfit, and they have been rebuilding steering gear boxes in the Seattle area since 1981, and over the last thirty years, they have built over 60,000 units. Along the way they have developed a process for rebuilding a gear box to a better than new condition, and the results speak for themselves. With a RedHead box, you’ll have a truck that drives straight and true down the road whether its stock or lifted, and you won’t find yourself fighting with the wheel. To truly understand what makes RedHead different however, you need to pull back the curtain and see what goes into their manufacturing process.

Like with any quality rebuild, the process starts with a core which gets disassembled and cleaned. All the critical parts inside like the piston, input shaft, sector shaft, ball-screw, and housing bore are measured and inspected. If the parts are within spec, they move on to the next step in the process, but if the gear teeth or housing bore are worn beyond repair, they hit the scrap pile. On every rebuild they do, RedHead puts the sector shaft on a lathe to precisely measure and verify its straight, because even a few thousandths of misalignment can cause binding and accelerated wear inside the box. If any critical bearing or sealing surfaces on a shaft are worn or undersized, they are treated with a process called flame spraying (look it up on YouTube, it’s very cool) which is a process similar to welding where material is added, and then the shaft is then machined back to spec. The housings are then bored out to accept oversized needle bearings which will give a much tighter feel when compared to the standard bronze bushing, and then it’s time to install some new seals so the fluid pressure stays where it belongs, and if needed, any updates are made to the valve assembly. One other unique feature offered by RedHead, is if you need the box tapped for an off-road hydraulic assist steering system, they are happy to perform the modification while the box is apart.

Next comes the part which makes a RedHead drive so much better than a generic remanufactured or even a stock box, and that’s fitting the bearings inside the ball-screw assembly. Most other rebuilders simply re-use the factory size balls, because they’re readily available. More often than not, the clearance between the helical raceway and the bearings is too large, and this will translate into excessive play in the steering, even if the rest of the box is within spec. On the other hand, if the clearances are somehow too tight, there will be binding and accelerated wear, which will lead to extra play in no time. Instead of using an off the shelf bearing size, RedHead takes the time to measure and custom order a specific size of ball bearing for every steering box they build, which ensures exact tolerances and minimal play as you drive the truck down the road. It’s said over 70% of the play in a steering comes from an improperly sized ball-screw assembly, so needless to say, this is an important step.

The very last thing to take care of on a steering box is to set the backlash between the sector shaft and the piston, and this adjustment is just as critical as the backlash in a differential, and represents the last 30% of play in a steering box. The gear lash on each box is adjusted and tested until it meets all requirements, and finally its shipped to you to install in your truck in its new permanent home.

Persistence Pays Off

The best feeling in the world is hopping into your truck after you’ve installed a new part and finding out it drives exactly like it should: straight as an arrow with no corrections needed on the steering wheel. It doesn’t matter if you have a stock daily driver, drag truck, or even a lifted off-road machine, a quality steering system makes all the difference, and allows you to enjoy and look forward to your driving experience instead of dread it.

07 Ford F-350 super duty 4×4 OEM steering box leaking oil. Looking for a good replacement part…

Thank you for the inquiry. We’ve had excellent luck and feedback from Red-Head’s replacement, part number 2768, shown here:

https://www.dieselpowerproducts.com/p-15255-red-head-steering-gear-box-05-07-ford-f-250-f-350.aspx

Please let us know if you have any other questions we can help with.

need a 99 f350 7.3 ford gear box 714 224-2951 thanks mike

My mechanic dislikes Red Heads. He has mentioned Steering Memory. In that a Red Head won’t return to stable center. But after 3 stock gearing boxes I am pressing him to upgrade me to a Red Head.

Is there or has there been any ongoing issues with Red Head boxes having “Memory Steering”?

We’ve been selling Red-Head gear boxes for about eight years at this point, and honestly sell quite a few of them due to their excellent reputation. To date, we’ve had zero issues with steering memory that we can recall, and it obviously would have been a noted issue if its something as problematic as your mechanic is describing. I’ve personally ran them on a few of my own trucks and its been one of the best upgrades I’ve done and truly makes a huge impact on the steering. Overall, its possible your mechanic had an issue with one, its not a perfect world, but in our experience, if there was an issue, Red-Head stands behind their product.

Shipping to Germany ??? Dodge RAM 2500 V10 8.0 1995 , 4×4

That will depend on your location in Germany, as well as a few other variables. The simplest method to get an exact cost would be to add the gear box to your shopping cart and enter in your complete shipping address. Follow the below link and you’ll be set:

https://www.dieselpowerproducts.com/-red-head-gear-box-94-02-ram.aspx

I bought a Red Head for my 01 Dmax 3500 4×4. I actually had to learn to drive it differently. Dang thing went so straight it was eerie. Needless to say I’m looking at replacing my 05 Dmax with less than 150k with the Red Head. I might add, the 01 has 350k and complete PPE Stage 3 steering components.

Thanks, Tom

i HAVE A 1995 CK2500 , 7200 GVW ,6.5 TURBO DIESEL , 4/W DRIVE THAT I ORDERED NEW 365,000 MILES AGO .. AT 170,000 ( EST.)IT WAS STARTING TO STEER LIKE A SADDELE ON A SOW SO i HAD MY CHEVROLET GARAGE REPLACE THE STEERING BOX WITH A AFTER MARKET BOX THAT I TRACTED DOWN FROM A REMANUFACTER SINCE I WAS UNABLE TO GET A NEW ONE FROM GM AND THATS WHERE IT GETS UGLY !! i HAVE JUST HAD MY CHEVROLET GARAGE REPLACE THE 5TH BOX ( NOT COUNTING THE ONE THAT CAME IN THE TRUCK NEW .. THEY HAVE BEEN LOSE AND OTHER ISSUES SO I HAVE TO BE VERY CAREFUL PULLING MY TRAILERS OR JUST DRIVING IT !! A CONVERSATION WITH MY GM MECHANIC (DOUG ) JUST A DAY AGO TOLD TO TO CHECK OUT ( RED TOP STEERING BOX’S) THAT HE HAS HEARD GOOD THINGS ABOUT THE PRODUCT … AFTER 200,000 MILES AND 5 STEERING BOX’S I AM READY !!! i AM OLD AND I BOUGHT MY TRUCK TO BE A LIFER SO I AM ASKING YOU IF YOU CAN HELP ME WITH SOMETHING AT WORKS ?? RESPECTFULLY STEWART W. ROSENDAUL – BRYAN , OHIO , 43506 TELE # 419-769-7979 ANYTIME !!

On my 2007 Chevy 2500HD Classic, I had the major front suspension components replaced, but still had play. Drove me crazy… Had a shop replace the steering box, and damned if wasn’t worse. I lost faith in that shop after they gave me the cold shoulder, so I went to Les Schwab and the old-timer tech said “I’ll put a RedHead steering box in there and I guarantee it’ll tight”…and it was. Oddly enough I drop parts off at a machine shop right next door to the RedHead shop in Auburn WA. I’m now a fan of RedHead (s)…