Written By: Lawrence “LT” Tolman

2011 was a big year for GM as there were a lot of major changes made to its HD truck line-up, but the crazy thing was, from the outside you really couldn’t tell. Most of the major body parts on the Silverado and Sierra were un-changed and only minor details would set a 2010 apart from a 2011. The visual changes included a slightly restyled front bumper and grille and slight tweaks to update the interior, but for the most part the visual appearance of the GMT900 platform was the same as it had been since they were released halfway through 2007. However, once you looked a bit deeper, it became readily apparent the two trucks were nothing alike. Just about every mechanical system of the truck had been updated to make the new HD’s stronger, burn cleaner, more powerful and able to tow heavier payloads. The re-design included an all-new fully boxed chassis to replace the earlier C-channel frame which had been around since 2001 and major revisions were made to the steering and suspension. The trucks sported a new larger wheel bolt-pattern of 8x180mm, the Allison transmission got several updates to make it hold more power and shift crisper and of course you can’t forget about the all new powerplant, the LML Duramax.

Details of the LML

By 2011, the Duramax lineup had already seen four major revisions, starting out with the LB7 in ‘01, moving to the LLY in ’04½, the LBZ in ‘06 and the LMM in ‘07½. In 2011, federal emissions regulations had tightened, so additional measures had to be taken to keep the Duramax compliant, so the LML was the first to be equipped with Selective Catalyst Reduction (or SCR), a system which used a urea-based exhaust fluid to break down harmful nitrogen oxides. Also included in the emissions arsenal was a 9th injector, or dosing valve, which sprayed fuel directly into the exhaust stream during a re-gen to clean out the exhaust filter. This eliminated the problem LMM’s had where diesel fuel would wind up in the engine oil, which could lead to major problems. So, by relying on an external fuel source for a DPF re-gen, the LML kept its oil free of any fuel dilution. Speaking of fuel, the LML was the first Duramax to be able to run on a B20 blend of biodiesel.

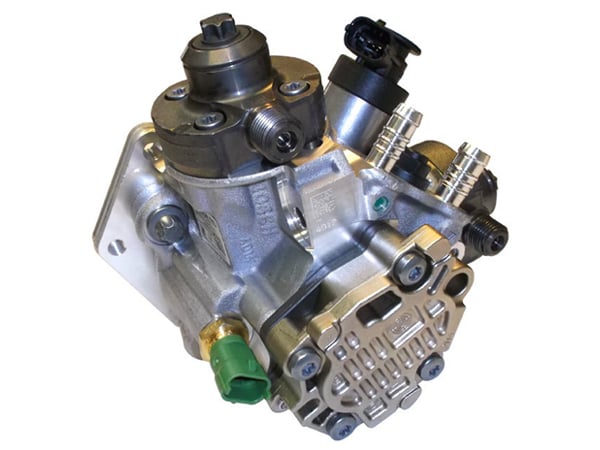

With its advertised output of 397hp and 765 pounds of torque, the LML was the most powerful Duramax to date. While there were several other mechanical upgrades to the internals of the engine like stronger pistons and rods, the biggest difference between the LML and all earlier engines was in the fuel system, which now centered around a Bosch CP4.2 injection pump and new piezoelectric injectors which operated at a much higher pressure than earlier models, topping out near 29,000psi. This higher injection pressure meant the fuel was atomized into much finer droplets, which resulted in more efficient combustion, formation of less harmful pollutants and everyone’s favorite, more power. That all sounds great on paper, but in the real world, things weren’t so simple. In fact, this new injection pump was the cause of quite a big headache.

CP4 Problems

The newest Bosch pump was very different from the earlier CP3; it features two piston pumping elements instead of one and each has its own camshaft lobe; it’s basically a V-twin injection pump. In order to produce such high pressure inside the fuel rail, the internal parts of the CP4 are machined to a very precise and tight tolerance and diesel fuel is the only lubricant the moving parts have, which is the root of the problem. Because of the physical properties of diesel fuel, it loves to collect water and other contaminants, neither of which are very good at lubricating metal.

If your fuel system hasn’t been maintained with regular filter changes or you get a bad batch of fuel, there can be a small amount of trash or debris that winds up in the CP4 pump, which can be just as dangerous as Luke Skywalker is to the Death Star. If they make it past the filter and into the pump, those tiny dirt or water droplets can actually act as an abrasive and cause small amounts of metal to wear away. As soon as one aluminum chip or shaving is dislodged, an irreversible chain reaction starts, which causes more and more wear to take place, which generates more and more debris, which in turn causes more wear and the cycle keeps getting worse until the injection pump won’t develop fuel pressure and the truck simply won’t run anymore. That sounds like an inconvenience, but those metal shavings aren’t just recirculating in the injection pump. When a CP4 lets go, it sends metal shavings directly into the main artery of the fuel system and first stop is the fuel rail, followed by the injectors, the return lines and ultimately, they’ll make their way back to the tank. In other words, your entire fuel system will be filled with metal shavings, your injectors will be toast and you aren’t going anywhere. The worst part about a CP4 failure is how little (if any) warning you get. In most cases, you will be driving around when suddenly you might notice a slight loss in performance. Sometimes you’ll get a “change fuel filter” message triggered by low rail pressure and other times you will get a check engine light with a DTC code relating to the fuel system (P0087, P0088, P0191, or P128E). The problem is, once the shrapnel gets into the fuel system and the chain reaction starts, you might only make it a couple more miles until the whole thing implodes and the truck is inoperable.

If you find yourself in this situation without a warranty, you may want to sit down for this next bit of news. GM recommends the following procedure in the event of a failed CP4: replace the injection pump, fuel rails, all eight injectors, all high-pressure lines, low pressure injector return lines and the fuel filter. On top of that, you’ll also need to clean out the main feed and return lines running the length of the chassis, all engine mounted rubber fuel lines, the fuel tank itself and even the sending unit. If paying out of pocket at a dealer, the total cost of parts and labor can exceed $10,000. The only consolation a Duramax guy might have as he reads his invoice, is in addition to the LML, the 6.7-liter Powerstroke is also powered by the Bosch CP4 injection pump and it too has a reputation of grenading itself.

Ain’t Nobody Got Time for That

It’s time for some real talk: the purpose of this article is not to scare you into selling your CP4 powered truck or to stop you from buying one in the first place. While the failure is a well-known issue, it seems the occurrences are hit or miss, sometimes even sporadic. With a little digging, it’s clear there have been some CP4 failures with as little as 30,000 miles on the clock, but at the other end of the spectrum, some have logged over 700,000 miles on their LML with the original injection pump still running strong. For most owners who have experienced the issue, it seems the average failure happens just under 100k and luckily GM’s warranty department picks up the tab for the repair. It’s also worth noting in 2018 a class-action lawsuit was filed against GM, Ford and Bosch for the early failures of the CP4 pump, however, it appears the case was dismissed for a bunch of legal reasons containing the phrase “denied as moot”. In my opinion, the CP4 issue is a bit blown out of proportion. I’ve spent a lot of time trying to find information on how many failures have occurred and it’s hard to get a solid number. The results of a few online polls and some simple extrapolation indicate less than 10% of all LML’s have had a failure and other reports suggest the figure is around 5%. Either way, the odds aren’t that bad. It seems the biggest issue isn’t how many pumps fail, but rather the cost to make the repairs after the failure happens. Even if you go to an independent repair shop and find the best possible online price for replacement parts, the cost of getting back on the road is a tough pill to swallow, when the repair can represent a huge percentage of the trucks actual value.

CP4 Fixes

Now that we’ve got the dirty laundry all aired out, it’s time to talk about how to prevent and repair the problem. It’s been proven the number one cause of a failing CP4 is the fuel that’s going through it so clearly it’s important to keep said fuel clean. I’ve mentioned this before, so it feels like I’m beating a dead horse, but regular maintenance is absolutely necessary on any diesel engine. As such, it continues to surprise me how many people forget to replace the fuel filter. I know it’s convenient GM builds in a fuel filter reminder which pops up on the dash when the computer calculates your filter is dirty, but rather than waiting for a computer to tell you, why not just go ahead and change it every 10,000 miles like a normal person? You’re never going to damage your engine by changing the fuel filter too often, but not changing it enough definitely has its risks. A good choice for a stock fuel filter replacement on the Duramax is the AFE Pro-Guard, which removes 99% of water and traps dirt particles 4 microns and larger.

While removing dirt and contaminants from your fuel is a good start, it doesn’t do anything to improve the lubrication properties of fuel in the first place. An old wife’s tale says you can just dump some ATF into the fuel tank, but don’t do that. Instead, use a proper fuel additive like F-Bomb. For the LML, the most important effect will be increased lubricity of the fuel (to help the CP4), but you’ll also get a bump in cetane, an improvement in fuel economy and for guys who park their truck more than they use them, it will prevent bacteria and algae from growing in your fuel (yes, algae like in a fish tank. It’s a real thing…)

One more way you can help extend the life of your CP4 is take away some of its stress. The CP4 is responsible for drawing fuel from the tank as well as pressurizing it, so by adding a lift pump and sharing some of the workload, its stress is greatly reduced, and the injection pump can work more efficiently. Taking a lift pump one step further and adding some additional filtration and air separation into the mix is the icing on the cake. The FASS Titanium Signature Series lift pump will remove dirt, water, air and debris from your fuel and sends 8-10 psi of fuel up to the engine. The 165 gallon per hour unit is the most popular and is ideal for engines making between six to nine hundred horsepower, but because of the way the FASS pumps are regulated, it will work perfect at much lower power levels and daily driving as well. If you need more fuel capacity than that, FASS also offers pumps that flow 250 and 290 gallons per hour, which will support up to 1,500 horsepower from a single pump. The best part is the high-efficiency filters only require changing every 30,00 miles.

One last trick to keep the CP4 from wiping out the rest of the fuel system is to swap out the inlet metering valve on the pump with a System Saver Inlet Valve. While it won’t stop a CP4 from failing and generating debris, what it will do is prevent the debris from wiping out the injectors and contaminating the rest of the system. They are very affordable compared to a set of injectors, and easy to install as well, so a worthwhile insurance policy by any standard. If despite all your best efforts you still have a CP4 wipeout, you’ll have to do some shopping. When it comes to injectors, your best bet is to go with a genuine Bosch OE replacement. They are made with all new construction, so there’s no need to send your cores back. Since you need to replace all eight after a pump failure, it might be worth your while to consider a larger than stock injector if you plan on boosting the power level. A 50hp set of injectors from Dynomite Diesel can add a little spunk to your LML since they flow 20% more fuel than stock and they’ll support around 650hp at the wheels while still being perfectly drivable and can also give a slight bump in fuel mileage.

As far as the injection pump is concerned, you’ll obviously need another, and you have some options as well. Of course, the easiest and most affordable option is to go with a stock replacement. Dynomite Diesel has you covered there as well and for just over 800 bucks you can have a direct replacement of the stock pump. One thing you might not know, is the CP4 has a built-in power disadvantage to the CP3 with its lower fuel volume, so one popular move is to swap it out with a CP3. A conversion kit from Industrial Injection makes the job simple, with all the lines and brackets you’ll need to install the earlier style pump. The benefits of a CP3 conversion are twofold: you’ll get a much more reliable pump right off the bat and more power potential as well. The basic kit can support 600 HP and if you want more than that, a larger displacement CP3 will swap right in, as well.

Chasing that High (Power Number)

Once the fuel system is taken care of, you’re pretty much out of the woods. Honestly, even with all the emissions components intact, the LML will be reliable for many years and miles to come. There are a few ways you can get into trouble however, but that’s usually a case of self-inflicted harm from being a bit too eager with the power upgrades. When compared to all the other stock Duramax engines, the LML has the strongest and lightest rotating assembly. The pistons are made from cast aluminum with a steel ring land and the design has been updated to make them stronger and less prone to cracking than the LBZ/LMM design. The LML connecting rods are made from forged steel, have roughly the same strength as earlier rods and are a few grams lighter. Even with all those improvements, the magic number for the power limit of a stock engine is somewhere around the 700-horsepower mark. Since that’s pretty easy to achieve with modern turbos and tuning, you’ll want to leave yourself some margin of error if you want your engine to last. But if you have the need for speed, just be sure to set aside a couple extra bucks, since you’ll inevitably be tearing out the engine for an upgrade sooner or later.

In order to keep maximum drivability, turbine braking and throttle response, the stock turbocharger on the LML is the smallest of any VGT Duramax. The vanes in the exhaust housing measure in at just over 11mm thick (down from 15), it has a 60.6mm inducer on the compressor wheel and a 62/70mm turbine wheel and the turbocharger will support 520-550 rear wheel horsepower. However, if you push your turbo to the edge, the exhaust drive pressure (and temperature) goes up tremendously since the turbine housing is such a major flow restriction. This is not a good thing if you want your internal engine parts to last and is especially problematic if you are thinking about compound charging your LML. Instead, you’ll first want to consider a turbo with a much less restrictive exhaust housing and taller vanes, like the Duramax Tuner Stealth 64. This would be a great upgrade from stock in terms of horsepower and reliability and the 64mm charger will still drive like a stock turbo. All this means towing heavy loads is still on the table, you’ll have great EGT control and the Stealth 64 will support 620 horsepower when used in a single application. If that’s still not enough, you can step up to the Stealth 67G2 which has all the same benefits as its smaller brother, but the big boy can lay down 800 horses.

What the Hell, Buy an LML?

So, the question becomes, is it worth owning an LML? In short, I believe the answer is yes. Over the five year span the engines were produced, there were two body styles of trucks that were equipped with the engine, the ride quality of which was greatly improved over earlier models (along with the towing capacity) and the interiors have plenty of creature comforts. Sure, you might have this constant fear lurking over you about the dreaded CP4 failure, but don’t let it get you down. The actual odds of a failure are much less than the internet would have you believe and with proper maintenance and a few simple preventative measures you’ll likely never experience a failure. If you still are worried, the best bet is simply to swap out the CP4 before it fails in favor of a CP3 and you’ll eliminate the problem altogether. The best part of doing that, is since your injectors won’t need replacing, you’ll have money left over in the budget for a set of compounds and a built trans.

Very informative for those like me, who have heard of the CP4 failure but have no experience dealing with or preventing it! Thanks

86000 miles and I’m almost positive this has just happened to me. The truck is a 15’ but bought in 14’. Tomorrow I’ll find out if a dealership will cover it. Hopefully they do

I just had the CP4 failure occur in my 2011 GMC Sierra duramax 2500HD at 170,000.

My mechanic gave me an estimate of $8 – $10K.

Checking to see if there is some recourse or buy back through GMC.

Unfortunately, we’re unaware of any recourse once you’re beyond warranty coverage. Very sorry to hear of the failure on your truck.

I searching for GM or Ford Diesel truck in the 2006 – 2011 range. I’ve been reading about these fuel pump issues and my conclusion, at this time, is to simply replace the CP4.2 with the CP3. Does this sound reasonable, given the high expense of a failure?

The good news is that if you’re searching in that model year range of 2006-2011, the only time you’ll run into a vehicle with a CP4.2 would specifically be a 2011 Chevrolet/GMC Duramax or 2011 Powerstroke, as that was the first year of the LML and 6.7 Powerstroke engines. Previous model years of Duramax would still have the tried and true CP3 where Fords had various models of an HPFP, not a traditional CP3. That said, yes, if you do end up with an LML, to be absolutely safe you would convert the system to a CP3 to prevent against any unforeseen failures. Regarding Ford, there are what as known as “Disaster Kits” that do not provide any preventative measures against the CP4 from failing, however, they do provide insurance that in the event the pump does fail, it does not send debris through the rest of your fuel system, essentially saving the injectors, filters, and so forth.

Great read and learned quite a bit, I for one am dealing with the LML failure right now, but it wasn’t the CP4.2. After diagnosing with snap-on scanner, multiple techs and a set of good eyes, we noticed harmonic balancer wobble. Bolts weren’t backed out, pins weren’t sheared off… no worries just a broken crankshaft and pretty heartbreaking with only 163,000 miles. No doubt in my mind after driving cummins, powerstroke and duramax I’ll still own a duramax.

Ouch, really sorry to hear about this! Obviously a big investment to fix this, if you need any help, don’t hesitate to give us a call.

I am looking at a 2015 duramax with 170,000 miles on it. the guy that is selling it says it was deleted before he got it (he bought it with 120,000 miles. The guy wants $25k, should I stay away?

The LML’s are a good engine, so I wouldn’t necessarily tell you to stay away the fact it has 170k on the odometer. That said, ANY truck with that amount of mileage will have certain things start to pop up that will need to be addressed. Because the previous owner deleted the emissions means they have some type of tuning, so see if they’ll tell you what kind of power levels they were running it on to gauge if the truck has been abused. Further, if you do plan on using any of the higher power levels, it will be in your best interest to install a lift pump, such as a FASS Titanium Signature Series and a cold air intake if one hasn’t been installed. Overall, that’s a good truck, just try to get some history on the maintenance and any repairs, be ready to possibly do a little front end work if it hasn’t been done, and enjoy it.

Texas Law Office has a active lawsuit against GM over this Deceptive and just shady acts GM has done to there customers by knowingly selling this bomb P.O.S. to us and never even warning us there was a problem !!!! I have bought 5 chevy duramax trucks in the last few years and I will never by a chevy truck again because of this. I got a 2015 4 wheel drive with 126k miles that i bought new and still owe 11k and these crooks want 10k to fix it !!! SHAME ON YOU GM !! JUST MAKE THIS RIGHT!!!! Tommy Temple

The issues with the LML fuel system are now rearing their ugly heads and showing just how much it costs to repair. Unfortunately, its essentially purchasing all new fuel components that are built exactly the same as what failed originally. Otherwise, there are things that can help, such as a CP3 conversion to eliminate the CP4 and upgrading the lift pump, but in terms of something from the dealer and them recognizing the issues, you’re exactly right.

Just bought a 2014 duramax with 84k miles. 3 hours down the road right from when and where j bought it and check engine light came on. Needs $8-10k. All new injectors plus all new suspension. Feel like I was scammed by a small town dealer

Wow, really sorry to hear about this. Hopefully the dealer you got it from will help you out in some way.

It wouldn’t let me respond to your response – giving me a 403 forbidden error. Anyways, I reached out and they said tough luck. However, i left a 1 star review and they said ownership will contact me. I doubt it, but who knows. Regardless…not knowing how this works…if mechanic was to replace all injectors, head, and return lines, am I basically getting a reset on the life of this truck? or is it entirely possible I come across another absolutely devastating repair due to tough luck/or this truck not having been maintained well? I’m wondering if I need to just bite the bullet and fix or trade in to a dealer even if it means losing $7-10k off what I spent on the truck.

Being that the injectors failed that early, its typically associated with bad fuel quality or lack of maintenance (i.e. fuel filter). We typically hear of injector and/or pump failures occurring more in the 120k+ range. That said, essentially you’d be looking at “resetting the clock” to give you another 100k-ish out of the injectors. That said, the stock CP4’s are known to fail, which ultimately leads to injector failure, as well due to the way that system is designed, sending shrapnel from the pump into the injectors. You could always chance it and just replace the injectors, but at the very least, we’d recommend having the pump tested and go through the rest of the fuel system to be safe. Industrial Injection, as well as a few others, have complete “Disaster Kits” that give you all of the components that typically need to be replaced, and even upgraded, when something like this occurs. But then you still have the issue of the suspension, not sure what’s going on there, but there’s numerous items that can be upgraded in that arena, as well, including something as simple as the addition of a steering stabilizer, something that GM completely overlooked on this truck. Below are a few links you can check out to give you some ideas on costs:

https://www.dieselpowerproducts.com/c-2195-2011-16-66l-lml-gm-duramax-fuel-related.aspx#/filter:cfm_manufacturer:Industrial$2520Injection

https://www.dieselpowerproducts.com/c-2206-2011-16-66l-lml-gm-duramax-suspension.aspx

My 2016 dmax have 72 200 kilometres and 3 times cp4.2 faillures .. but on warranty .. but why they keep installing that shitty cp4.2 and tell me that cp3 or lift pump will void my warranty … so stupid…….

And that’s the glory of a warranty! Some will take the path of waiting until their warranty runs out, then making the proper repairs to avoid issues in the future, where others will see the amount of downtime they have while the parts are being covered under warranty along with any headaches caused by it, and then make the motion to upgrade even while under warranty to avoid those issues. In regards to their statement about voiding your warranty: Legally, they cannot just void your warranty for installing a CP3 conversion, however, they would not be responsible for any warranty repairs on the conversion kit itself, and if the conversion kit caused any other issues to the factory parts and they can prove that, those would not be covered under warranty.

I’ve got a 2014 lml with 265k on it. This truck rides so much better than my lbz. I bought it 4 years ago with 175k on it. It has been a beast. Only issues I have had are tcm, axle seal and thermostats.I deleted it immediately after getting it, ppei program and Kennedy lift pump. But let me be the first to say I am religious about maintenance and don’t dog it unless I’m pi$$ing off a teenager. Change the oil every 5k and fuel filter every other oil change. At $100 bucks for the filter change it’ll take a lot of filters to equal the cost of a fuel system.

I am looking at getting my first Diesel, found a 2011 Chevy 2500HD with about 153k miles, according to carfax it looks like it was serviced every 6-10,000 miles, fuel filter replaced every 40k, glow plugs and axels seals at 80k, at 104k it was sold and the details get less detailed….

It is is great shape and the new dealer has put some work into it to get it ready to sell….I know no one can tell if something will break, but it seems to have well loved early at least.

Any thoughts?

Congratulations! The LML’s are a great truck truthfully and sounds like this one has been meticulously maintained. That said, it does have 153k miles on it so there is going to be some typical wear items that will need to be addressed, of course (brakes, wheel bearings, potentially even a transmission refresh). The only really troublesome area is with the CP4 injection pump as mentioned in the blog, plus potentially the turbo may be getting ready to be rebuilt or replaced. Unfortunately, there’s not a great way to test the CP4 beyond verifying its output pressure, but not necessarily whether its on the verge of going south unless you take it off and disassemble. In my opinion, based upon the information you’ve provided, I’d say BUY IT!

Great read. I’m just about to turn 300,000 miles on my (deleted) ’11 Duramax. Best truck I ever owned, and no issues ever. Glow plugs at about 200,000 and just now had to change water pump and hydro boost. That’s it. Would highly recommend the lml!!!

But now you got me thinking about the cp4… lol

And thanks for taking the time to read it? A well maintained and taken care of truck will undoubtedly last as you’re proving. Use the right fluids all around, fix things when they break (or before), and you’ll get the mileage out of them. In regards to your fuel system, it could be a combination of staying up to date on your fuel filters, running quality fuel that’s not sitting in storage for months on end, and maybe a good fuel additive and conditioner that’s giving reason to your system lasting. Either way, keep it up! And when you’re ready, we’ve got kits that can fix your system if the need ever arises. Thanks again!

Great read! I’m looking at buying a 2011 duramax. It has 210k on it and the injection pump was replaced in 2011 when the pickup had 9k on it. It still has all emissions on it and no other major work other than replacing 5 glow plugs at 210k wondering of its potentially a good buy

Thanks for taking the time to read. As long as the entire truck has been regularly serviced and not abused, it definitely has life left in it for sure. That said, at the current mileage, you’ll be looking to replace some items that do typically wear in that 200k range, such as the turbo, potentially the injection pump again, some front end parts, and potentially even the transmission. It wouldn’t hurt to have the truck gone through to check for injector return rate, look for excessive play in the turbo, and line pressure in the transmission.

I have a 2016 Duramax 3500 with 80,000 miles. So far no problems what so ever. I bought it 2 years ago and shortly after i started hearing about the fuel pump failure. Every thing i can find out about this problem is the cheapest way to be safe is use a good additive that lubricates the fuel, such as Standadine (not sure on spelling) or something that says lubes all moving parts. Am i doing the right thing or should i be doing something else. Its a great truck and it pulls loads really well but in the back of my mind this makes me wonder. What do you suggest .

Ed, thanks for taking the time to read our blog post and sending us a question. Fuel quality is extremely important in keeping your fuel system together, yes. Unfortunately, years ago when fuel was required to switch to ULSD that only had 15ppm of sulfur from the previous ~500ppm, lubrication was lost. There’s a few things you can do to help, though. First, yes, running a good fuel additive like Stanadyne is a great first step. We run Fuel Bomb Diesel Additive in our own vehicles and have always had very good luck with it:

https://www.dieselpowerproducts.com/p-7522-f-bomb-diesel-fuel-additive-fuel-bomb.aspx

Secondly, get your fuel from a reputable source that cycles its fuel frequently to avoid condensation building up in the storage tank. Typically, larger stations or truck stops are a good source. Next, make sure you’re following the schedule to replace your fuel filter.

Finally, if you want to be absolutely certain that the CP4 doesn’t fail and send shrapnel through your injectors, some will go as far as replacing the CP4 with a tried and true CP3 with one of the example conversion kits below:

https://www.dieselpowerproducts.com/fleece-cp3conversion-11-16-lml-duramax

https://www.dieselpowerproducts.com/p-industrial-injection-436401-cp4-to-cp3-conversion-kit-11-16-66l-gm-duramax-lml

Hope this information helps and that your LML Duramax keeps running strong for you! If you have any other questions, please let us know.

Good evening, Looking for some insight/advice on a potential purchase of the following vehicle as my first diesel.

201 3 Silverado 2500HD LT 6.6 Duramax

Single owner and maintained at dealership, primarily used as a boat/trailer hauler and low mile commuter to and from school around 35 miles round trip.

Truck has 69000 original miles and single owner

Asking $45k which includes, wheels, tires, lift, air bags, toolbox fuel cell and a few other extras.

Any advice is appreciated

Hi there, Scott, and thanks for the question. With only 69k miles on a 2013 model year, that’s a heck of a find! The good news is that it sounds like maintenance has been kept up pretty well if the previous owner was relying on the dealer, so simple stuff like oil changes, fuel filter, etc. were being done on a regular basis. Now, as far as things to look out for: the first would be in relation to the truck being lifted, is the overall front end, especially the tie rods, upper control arm bushings, ball joints, and idler arm. Possibly the truck is only leveled, maybe its lifted, but depending on the brand of lift and how well that’s been maintained, what components were upgraded/replaced with the lift, can determine the integrity of the front end. The previously mentioned are common wear items on even a stock height Chevy HD, but even more so once its been lifted. If you haven’t done so already, drive the truck, rocking the wheel back and forth as you’re driving, hit some bumps, and try to get a general consensus on how tight the front end feels. Otherwise, you could also request to have the front end gone over by an alignment shop. The below category houses a ton of upgrades for your front end, whether its done as preventative maintenance or once failure does occur.

https://www.dieselpowerproducts.com/c-2206-2011-16-66l-lml-gm-duramax-suspension.aspx

One other thing to be on the lookout for is the CP4 injection pump. In model year 2011, Chevy opted to change to a CP4 from the tried and true, proven CP3, and honestly, the CP4’s just aren’t as “robust” as the CP3. The only preventative maintenance that can be done to help this is number one, make sure the fuel filter is changed regularly and run a good fuel additive to add lubricity. We personally use F-Bomb Diesel Additive:

https://www.dieselpowerproducts.com/p-7522-f-bomb-diesel-fuel-additive-fuel-bomb.aspx

Beyond that, some will go as far as replacing the CP4 with a CP3 using a conversion kit, such as the below:

https://www.dieselpowerproducts.com/fleece-cp3conversion-11-16-lml-duramax

But overall, see if the seller has records of all of the maintenance and have the front end gone over. Other than that, sounds like a great truck with low miles that should last you a long time.

Response to Diesel Josh (0922 on Aug 25,2021)

Thanks for all of the info and links for specified parts and items.

The truck was lifted with a Pro Comp adjustable 5-7″ lift, it also has Firestone airbags in the rear.

I willl be taking the truck for another test drive and pay particular attention to the front end feel when I do, as I recall I remember the front end feeling stout and properly responsive.

Again, thanks for all the information.

Scott

You’re welcome, and if you have any other questions, feel free to contact us. For your own reference, I believe the below is the lift on the truck, so you can have an idea of whats involved. The system appears to be pretty thorough including the main components like diff drop, torsion drop, steering knuckles, and so forth.

https://www.procompusa.com/product-skus/pro-comp-6-inch-lift-kit-with-es9000-shocks-k1085b/

Bought a new 2012 Duramax 3500 in 2013. It has 300 k plus. Deleted emissions at 100k and added lift pump. Not having any issues. Using it to hual oilfield tools. Going into the shop next month,replacing water pump, belt and all pulleys, all hoses alternator ac compressor clutch and converting C4 to C3 injector pump. Should I replace injectors or anything else?

Always used truck stop fuel never any additives.

John, thanks for the question, always like to see a high mileage truck still on the road and serving its purpose. Also, good move on the CP3 conversion, that’s a great investment. In regards to the injectors, sure, in a perfect world, you’d replace them with everything else as they’re definitely at the mileage you should at least be seeing an excessive return rate, which will turn into failed injector(s) sooner than later. What I would recommend is while the truck is in the shop getting all of this work done, have the mechanic do an injector return rate test to verify the health of the injectors. While they’re in there doing the CP3 conversion would honestly be the time to replace the injectors, but its obviously another large expenditure. The good thing about the piezo injectors compared to their common rail predecessors is they have shown to have a longer life, definitely evident in your circumstance as common rails would definitely need to have been replaced by now.

Informative article. I have a 2013 DuraMax. When hauling a heavy load up a grade check engine light comes on and truck jumps into limp mode. Pulling off the road I turn the truck off and start it right back up and off to the races we go. Intermittent problem, but always pulling a grade with a load. Ideas?

Dale, thanks for the question. Obviously, the truck is sensing an issue when under load and basically trying to “protect” itself and I would hedge towards the fuel system being the culprit. First things first, I’d recommend changing the fuel filter. If the truck is still giving issues after that, verify if there are any check engine lights being thrown, or possibly stored fault codes that aren’t displaying on the dash to lead you in a better direction. If there are no codes and the truck is still acting up, I would recommend having the return rate on the injectors tested. Hopefully a stored fault code is present and I’m wondering if the CP4 injection pump isn’t delivering the commanded pressure due to a weakening pump. GM switched to the CP4 in 2011 away from the tried and true CP3 that had been used since 2001 and there have been a TON of reported failures to the point where there are numerous conversion kits on the market to revert the the LML’s back to a CP3.Further, the lack of a low pressure lift pump on those trucks, especially if you’ve added additional horsepower via a programmer could be causing the issue. The simplest fix for that would be the addition of an Fleece, AirDog or FASS fuel system.

Here’s an article that discusses adding a lift pump:

https://www.dieselpowerproducts.com/blog/when-is-it-time-for-a-lift-pump-on-your-duramax/

An example of a CP3 conversion:

https://www.dieselpowerproducts.com/p-industrial-injection-436401-cp4-to-cp3-conversion-kit-11-16-66l-gm-duramax-lml

AirDog Lift Pump:

https://www.dieselpowerproducts.com/p-15498-pureflow-airdog-ii-4g-a6spbc260-100-gph-air-fuel-separation-system-11-14-66l-gm-duramax-lml.aspx

FASS Lift Pump:

https://www.dieselpowerproducts.com/fass-ts-c11-165g-fuel-liftpump-duramax

Fleece Lift Pump:

https://www.dieselpowerproducts.com/fleece-in-tank-lift-pump-lml-duramax

We own a 2011 Sierra 3500HD purchased new, and since then we’ve been living full-time in a slide-in camper in the bed. Twice a year, it’s driven cross country fully loaded, with a utility trailer, over mountain ranges, and hills. We’ve maintained it religiously, and other than DEF issues in yrs 1 & 2, it’s given us no problems. Two years ago (after discovering the CP4 issue) I added a FASS system. At 120,000 mi, it blew a head gasket (just bad enough to inject some exhaust gasses into the coolant system under load, but still drivable). After 12 trouble-free years, we’re just now having to put some serious money into it, since it’ll be torn down to the heads anyway. (CP3, turbo, motor mounts, injectors, alternator, cooling system, oil pump, and a partridge in a pear tree). Expensive, but we love the truck that much… And it sure beats $90,000 for a new one. Here’s to many more trouble-free years(?)

That’s great to hear, Dave. The LML Duramax has for sure proven itself, like its predecessors to be quite reliable and with plenty of power. You mentioned some of the weaknesses of that truck but compared to some of the other vehicle options (won’t name any names around that era), I’d have to agree the Duramax is an excellent choice. Pretty cool to hear you’re full timing it in a slide-in camper, most of the time when I hear similar, its out of a 38′ (or larger) 5’er. If we can help with any of the parts selection are you’re doing the tear down, please let us know.

As good as this article is, I feel the need to add another LML issue to watch for: Cracked pistons. It seems as part of the emissions reduction design, the pistons had lips added to them to increase heat/compression. This was supposed to aid in burning off pollutants, but also results in pistons cracking sooner than they normally would. As I mentioned in my earlier post, we had our engine torn down for a head gasket job. When it came time to clean the block/cylinders, we were called in to check out the damage: 5 of 8 pistons had cracks forming. This is on a well-maintained, deleted, normally used truck. We had the bearings changed, and put in Mahle delipped pistons as well. Knowing what we know now, having gone through this 2-month process… My advice to LML owners is to save up some money, eventually, you’re gonna need it. The only upside, is that even after all the upgrades, and labor… We’re still WAY ahead vs. buying a new truck. There’s a mechanical engineer on YouTube, who’s got an LBZ he used to haul RV’s around the country for a living. His truck has over 1,040,000 mi on it, and the only work he’s done is injectors and a pump. What a difference emission controls make.

I have found a 1 owner 2011 2500 LTZ with 124k miles on a used lot.It appears to be in excellent condition 31k. I am a long time Chevy truck owner but this would be my first diesel. How can I tell if the injector pump has been changed to a CP3 ? I just bought a small 5er looking for some power the mountains.Would this truck be worth changing pumps and taking a chance on. Thx

Jeff, sounds like a great, low mileage truck! Honestly, the LML’s are a great platform and will make towing your 5th wheel through the mountains a breeze. You’re right, though, the CP4 pumps are concerning and we were glad to at least see when Ram switched back to CP3’s after only two years of CP4’s, but that obviously doesn’t help you. Now, in terms of seeing if the pump has already been switched out, the easiest would be to look at the below link that shows a side by side comparison. On the left is the CP4 and on the right is a CP3:

https://www.dieselworldmag.com/wp-content/webp-express/webp-images/uploads/2021/08/03-2.jpg.webp

Fortunately, if the truck hasn’t been converted yet, its a relatively straightforward process and below is a link to Fleece’s version of the conversion kit:

https://www.dieselpowerproducts.com/fleece-cp3conversion-11-16-lml-duramax

I hope this helps, and if you have any other questions, don’t hesitate to reach out.

You may have read my previous contribution on my 2011 3500HD rebuild. It’s been 8 mos since the rebuild, and an irritating, hard to diagnose, failure occurred I wanted to share (Common on the LML). For no apparent reason, the truck would randomly pop/smoke/knock. It would run fine in the mornings, but in warmer temps, it would run like it was missing… Serious “chitty chitty bang bang” type of symptoms. It wouldn’t throw a code, and multiple shops couldn’t figure it out, and often couldn’t replicate the symptoms. Well, long story short… It was the injector connector for cylinder 7. Apparently the LML is known to have this issue on 2 cylinders, #7 being one of them. I wish someone had found it before we limped at 25mph in 3rd gear, knocking/smoking, on a busy rural 2-lane in WY. Also… Avoid the Garrett Powermax turbo, drivability goes down the crapper. Hope this helps someone down the road.

David, I really appreciate you sharing this information and so glad you were finally able to get to the bottom of your issues.