Written By: Lawrence “LT” Tolman

Unless you’ve been living under a rock for the last 15 years, you’ve no doubt heard a ton of talk about turbochargers, as they are becoming the most popular type of power adder for both the aftermarket and the OE’s. Their primary function is to force more oxygen into the combustion chamber of the engine and increase power output, but how they work is a bit more complicated. All diesel pickups trucks for the last 20+ years have been equipped with a turbocharger, and if you’re looking for a bump in performance, sooner or later you’ll have to modify or replace the turbo with a larger unit. Today we’ll be discussing some of the basics of turbocharging, and some of the most popular and useful upgrades for towing, daily driving, or racing.

The Details

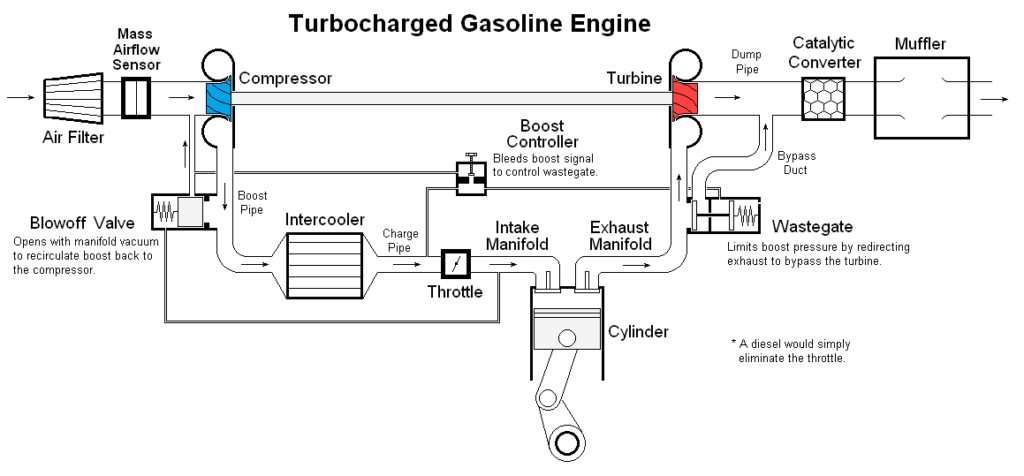

A naturally aspirated engine relies on the suction of the piston traveling down in the cylinder to draw in the air needed for combustion, and how much power the engine can generate is directly proportional to how much air it can suck in on every given stroke. One way to drastically increase power and torque is to force extra air into the cylinders, and there are several ways to do just that. A supercharger is a mechanical air pump which is driven directly from the engine, usually through the serpentine belt. This works great at adding power, but the supercharger also takes a massive amount of horsepower to turn. A turbocharger on the other hand, uses “free” energy from the exhaust to add power. Here’s the theory: the byproduct of combustion (exhaust gasses) are plumbed to the inlet of a turbine housing, spinning a turbine wheel and shaft. On the other end of the shaft is a compressor wheel, which draws in fresh air from the atmosphere, and forces it into the intake system of the engine. There are several benefits to using a turbocharger: it’s much more efficient at generating airflow than a supercharger, there is very little parasitic loss on the engine, and generally it can increase fuel efficiency as well.

The trick to turbocharging is finding the correct size compressor and turbine to do the job at hand, and as you can imagine there is no one-size-fits-all solution. From the factory, a diesel engine will be equipped with a relatively small turbo which will respond quickly to throttle inputs and generate a lot of airflow at a lower RPM. In higher-performance applications, the turbocharger will be comparatively larger and will produce much more pressure and volume at high engine speeds, but the trade-off is a much slower response to throttle input; this delay is what’s known as turbo lag. The main goal of turbocharging an engine is balancing lag with total horsepower potential, and you need to find the sweet spot for each particular application.

Geometry 101

The earliest and simplest turbochargers have what’s known as fixed geometry; other than the turbine and compressor wheel, there are no moving parts. Exhaust goes in one end, and compressed air comes out the other, and there is a narrow operating range where the turbo is most efficient. In an effort to expand the usable powerband, variable geometry turbochargers first saw widespread use in the early 2000’s. Inside the exhaust housing surrounding the turbine wheel are a series of vanes which direct the exhaust flow to different parts of the turbine wheel. By controlling the flow of the exhaust, the vanes can make a turbocharger behave like a smaller more responsive unit at lower RPM, yet still have big airflow potential at higher RPM ranges.

One useful feature of a variable geometry turbo (commonly referred to as VGT) is its ability to act as an exhaust brake. When towing, the vanes can be fully closed during deceleration which produces back pressure in the exhaust and will very effectively slow the truck down, even with a heavy trailer. Turbine braking is also a great way to reduce the workload of your service brakes, and even if your VGT truck wasn’t equipped with a turbine braking feature from the factory, most custom “tow” tunes will enable this feature, since the hardware is already in place.

Single Turbo

With the theory behind turbocharging taken care of, lets look at some real-world applications. With the exception of the 6.4-liter Powerstroke, every late model diesel truck was originally equipped with a single turbocharger. While there are many important dimensions to sizing a turbo, the one by which all are compared is the diameter of the inducer of the compressor wheel. Most trucks with an engine size between 5.9 and 6.7 liters have a stock turbo which measures in somewhere between 58mm and 62mm, which works great for producing high torque at low engine RPM, exactly what is needed for heavy towing and industrial use. From a performance standpoint, all factory turbochargers have some meat left on the bone and can produce more power than stock. Depending on the turbo, 450 to 500 horsepower at the wheels is usually a safe and realistic goal to shoot for. You can get more power without a doubt, but the law of diminishing returns certainly applies. The harder you push a turbo, the less efficient it becomes at generating airflow, and once you go beyond its efficiency zone, it will just create more and more heat, which causes more stress on internal engine parts, namely the pistons.

If more power is your goal, then a larger turbocharger is an important step on your pathway to success, but how big should you go? If you want to stay with a single turbocharger, there are plenty of options, and the simplest is a drop-in upgrade that retains the factory variable geometry system. Companies like Calibrated Power offer turbochargers which fit directly in place of the stock unit, with zero modification required. A Stealth 64 (64mm inducer) will raise your power ceiling of a Duramax to 650 wheel horsepower while retaining factory-like spool-up and turbine braking, and if you go a step further to the Stealth 67G2 (67mm inducer) you can max out at 800hp, while keeping the wide torque curve a VGT charger is known for.

One other popular single-turbo option is to convert to a fixed geometry charger. On the 6.7 Cummins in particular, the moving parts of the VGT actuation system can clog with soot and become inoperable. In addition, the physical position of the exhaust manifold on the 3rd and 4th gen Ram is very restrictive, limits how much larger of a turbo you can install. So, by using an exhaust manifold from an earlier 2nd gen Ram, the turbo is shifted toward the center of the engine and angled up, which means you can install a larger and more robust S400 style turbocharger which has no VGT parts to stick, and a much larger center shaft and bearings. While you will give up the OE turbine braking ability and a slight amount of spool-up, you do gain tremendous airflow potential, a less restrictive turbine housing (lower EGT), and the classic exhaust note of a 12-valve Cummins. For the daily driver that tows, the smaller S463 will have great response, and for the street/strip or weekend warrior type, a S467 with a 67.7mm inducer is the perfect option, which can support nearly 800whp, but even larger turbos can be installed. Just keep that all-important balance in mind; while a single 75mm S400 can support nearly 1,000 horsepower, it will require big fueling upgrades, a looser converter to help spool-up, possibly a gear swap, and certainly a whole host of other drivetrain parts to support the higher power level, and its “drivability” will be less than ideal. You can expect a laggy and smoky take-off until the turbo comes alive, but when it does, it will be like a light switch. While a tire shredding big turbo Cummins sounds appealing, you’ll have to forget about towing, as low RPM boost is non-existent, which means EGTs will be through the roof until the turbo comes alive. A single turbo will always be a compromise between overall power and response, but if you bring another friend to the party, your horizons can be expanded. Let me introduce you to the twins…

Compound Turbos

If one turbo is good, then two must be better, right? The concept of compounding boost is simple. Take a smaller and highly responsive turbo and combine it with a larger one which has a much higher volume, and you have the best of both worlds: massive power and minimal lag. If you’ve seen pictures of a compound setup, the plumbing might seem a little complicated, but it’s easy to explain if you break up the hot and cold sides. First off, the exhaust: it leaves the engine like normal and enters the turbine housing of the smaller turbocharger. The spent gasses exit the first turbine housing, but still have some energy left, so they’re sent to the turbine inlet of the larger charger. After it spins the second turbo, the exhaust exits to atmosphere. On the cold side, it starts with the larger turbo sucking in fresh air, pressurizing it, and pumping it into the compressor of the smaller turbocharger. The air is now compressed further, and sent on its way through an intercooler, and ultimately into the combustion chamber of the engine, where it will be mixed with fuel and burned. The larger turbo in a compound system provides a high volume of air at a relatively low pressure, and is somewhat slow to respond at lower engine speed, but it complements the smaller high-pressure turbo which is very responsive, giving the best of both worlds.

Much like in a single setup, turbo sizing is very important in a compound arrangement, and the best place to start is actually with your factory turbo and simply add a larger one on top, especially if you are using your truck in an application where you tow heavier loads for a sustained amount of time. We all know the importance of EGT control, and even a stock sized turbo can get a little toasty with a big trailer attached. One surefire way to cool things down and add some power at the same time is to throw some more air into the mix, and an ATS Aurora 7500 Compound system will do just that.

By utilizing your factory VGT charger on the manifold as the high pressure stage, you can keep the quick spooling characteristics and the exhaust brake the stock turbo is known for, but by adding the 80mm Aurora 7500 as the high volume turbo, the overall torque curve is extended, exhaust gas temps go down significantly, and if you can manage to keep your right foot off the carpet, you will even see a gain in fuel mileage. On top of that, most “add-a-turbo” systems using the stock VGT charger are very easy to install, require very few supporting mods, and offer huge bang for the buck. Depending on the kit, an add-a-turbo system will run out of steam in the neighborhood of 750 horsepower, with the bottleneck being the exhaust side of the stock turbo.

If you have more ambitious power goals but still like the benefits of a VGT, the next logical step would be to swap the stock turbo with a larger Fleece Cheetah or Duramax Tuner Stealth series turbo. A 67mm VGT compounded with an 80mm fixed geometry turbo together can reach power numbers approaching the 4-digit realm at the rear wheels (with supporting mods of course) all while keeping great street manners, quick spool, and low smoke output. And while you might not be able to tow at max GVWR, lighter duty hauling is not out of the question.

Competition

If you have ambitions of breaking power records with your truck, you’ll realize most commonly available sizes of VGT turbo will be a hinderance over the 900hp mark, even when compounded. The turbine and compressor housing of the smaller turbo physically can’t flow enough CFM, and acts as a bottle neck. For drag racing or dyno competition, a 72mm turbo may be combined with an 88mm or larger for the ultimate in high RPM horsepower. In other types of racing, a two-stage triple-turbo setup can be used, where two medium size turbos act as the low-pressure atmospheric charger, and a single larger turbo is the high-pressure stage. On the ragged edge of tractor pulling, some triple-stage quad-turbo setups are known to produce in excess of 300 psi of boost.

Other Components

Once you have your turbo arrangement picked out, there are a few additional upgrades you’ll want to consider which are just as important as the size of the turbo itself. According to the laws of physics, any time you compress air, its temperature will rise, and since warmer air is less dense, it can contain less fuel. Simple math says that warmer air and less fuel will reduce an engines potential to make horsepower. To beat the heat, an intercooler goes between the turbocharger and the engines intake and increases the density of the compressed air making its way to the engine. Just like a stock turbo has its limit of airflow, a stock intercooler can reach its limit as well, and become a flow restriction, and in the case of certain Duramax trucks, the plastic end tanks can even burst under higher pressure. A more efficient intercooler like the Banks Techni-Cooler can flow more CFM, has less pressure drop across the core, and the all-aluminum construction can withstand higher boost pressures, all while removing more heat from the air charge, and ultimately giving your engine more power.

A wastegate is a valve that installs between the engine and turbo, and its main function is to control how much exhaust spins the turbo and allows the excess to bypass the turbine. A wastegate is most commonly used on trucks with a fixed-geometry turbo, but can be used in VGT applications as well. The drive pressure between the engine and turbine can become too great, even with the vanes all the way open. So, by installing a wastegate, excess drive pressure is vented around the turbo, clearing a back log of sorts. This makes room for more fresh air to enter the engine and make more power. In a compound kit, the wastegate can allow the exhaust to bypass the first turbine if the back pressure is too high and divert it into the second turbo so the exhaust energy is not wasted.

We’ve mentioned how the vanes of a VGT turbo can act as an exhaust brake, but those benefits can be applied to a fixed geometry turbo as well, which is especially useful if you’ve done a second-gen swap. A BD Universal inline exhaust brake fits either 4- or 5-inch exhaust depending on your application and supplements your service brakes with an additional 150 retarding horsepower to slow the heaviest of loads with ease, just like the stock turbo did.

Thanks for the turbo discussion. Really helps to understand exactly how they work and what they do for increased performance.

Are questions regarding specific problems and personal experience in diesel engine performance appropriate on this website? If so, I have some questions regarding performance at higher altitude as well as combating high EGT on a second gen 5.9 12 valve.

Hey there, thanks for reading and the question. Yes, you’re absolutely more than welcome to ask questions here and we’ll respond. You’re also welcome to send us an e-mail at [email protected] or give us a ring at 888-99-DIESEL, the choice is yours! We’ve got plenty of experience with 12 valves, turbos, and higher altitudes with some of the issues that come along with the denser air. We’ll ask a lot of questions such as what you’re using the truck for, how much power you’re making now, how much you want to make, what other upgrades you’ve done, what gear ratio you have, and what size tires you’re running. Looking forward to help!

Just bought my first diesel truck-a 2008 Ram 2500 for daily use and towing my RV. I want to increase the hp, torque, and fuel economy without deleting, lifting, nor big wheels. I want to keep the extra money for fuel and fun.

First, congratulations on the new-to-you truck! Fortunately, there are numerous, simple bolt-on upgrades for your truck that can deliver additional power and fuel economy, without “going overboard.” Really, as long as upgrades are done tastefully and the right combination, you can have everything you’re looking to achieve a great balance. For instance, starting with a good cold air intake, then adding a chip/programmer, and rounding it off with a bolt-in turbo upgrade can make an absolute world of difference. And guess what, that extra power will also give you some of the “fun” you mention.

Here’s a couple examples I’d recommend looking at. Also, when time permits, I’d recommend calling in and you can discuss the overall goals you have, or shortcomings you’re trying to overcome, and we can put together some recommendations based upon that.

S&B Cold Air Intake:

https://www.dieselpowerproducts.com/sb-cold-air-intake-075-09-cummins

Edge Juice with Attitude:

https://www.dieselpowerproducts.com/edge-juice-w-attitude-cts2-67l-cummins

Smarty Touch:

https://www.dieselpowerproducts.com/smarty-touch-programmer-985-18-cummins

BD Screamer Turbo:

https://www.dieselpowerproducts.com/smarty-touch-programmer-985-18-cummins

Fleece Cheetah Turbo:

https://www.dieselpowerproducts.com/fleece-holset-vgt-cheetah-67l-cummins