When the 7.3 and 6.0 Powerstroke were introduced, there was one significant design flaw they both shared that could have easily been fixed but was instead ignored for years. While it might sound insignificant to some, the path that diesel fuel takes through the engine abruptly comes to a stop at the end of each cylinder head. This can lead to a myriad of problems, but thankfully the aftermarket has stepped up and offered some great solutions to the shortcomings on the Powerstroke. To fully understand the fuel routing problem with the 7.3 and 6.0 Powerstroke, we need to take a closer look at its most unique feature, the HEUI injection system.

Your Grandfathers Diesel

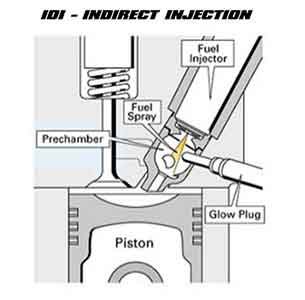

Fords earliest diesel engines installed in pickup trucks featured a mechanical injection pump. The 6.9 IDI and 7.3 IDI were relatively efficient and made OK power, but they used a slightly outdated design that injected fuel into a small “precombustion” chamber where it mixed with air and was ignited by a glow plug. Once the air/fuel mixture ignited, it traveled from the precombustion chamber and into the main cylinder where it moved the piston to create power.

This indirect injection design was used with slight variations from 1983 until 1994, but as the mid 90s got closer, Ford needed a more powerful, smoother, and cleaner running engine to compete with the 5.9 Cummins used by Dodge. The solution was released midway through the 1994 model year, and it was known as the 7.3-liter Powerstroke. Even though it shared the same displacement, it was a completely different engine from the 7.3 IDI that preceded it, and one feature that set it apart from all other diesel engines since was the use of HEUI injection.

The mechanical injection pumps used on the 6.9 and 7.3 IDI create around 2,000 PSI of injection pressure, but a number closer to 10x that was required for the first Powerstroke to meet its power and efficiency goals. To produce that much fuel pressure, the engineers at Navistar (the company who actually built the 7.3, 6.0, and 6.4 Powerstroke) had to get creative. They (along with help from Caterpillar) devised an injection system known as HEUI (Hydraulic Electronic Unit Injector) which utilized high-pressure engine oil and an intensifier piston to force fuel directly into the combustion chamber, and because the injectors were electronically controlled, injection timing and duration could be varied to maximize usable power throughout the RPM range. While the later 2003.5 to 2007 6.0 is a completely revamped engine, it still utilizes the same style HEUI system, and had the same problems with fuel routing. The 7.3 and 6.0 both have two oil pumps inside the engine, one for lubricating the moving parts like the crankshaft, camshaft, and rocker arms, and a second high-pressure oil pump (HPOP) that sends oil through a separate passageway into each cylinder head, and into the body of each injector. An electronic solenoid fires when commanded by the ECM, which lets the high-pressure oil flow into a plunger chamber, which in turn forces the intensifier piston downward. On the other end of the piston is fuel, which gets forced through a series of tiny openings in the nozzle as the piston descends, and it goes directly into the cylinder.

HEUI Fuel Path Problems

The fuel starts its journey as a dinosaur roaming earth well before time was measured, but more recently, when Littlefoot and Ducky get pumped into your tank at the filling station. From there, a low-pressure fuel pump moves it from the tank towards the engine. Once it’s at the engine, it goes through a fuel filter and regulator assembly (fuel bowl) where the fuel is cleaned, and the pressure is set. Depending on how much power is demanded, most of the fuel goes from the bowl into the cylinder heads where the only way out is through the injector. Any excess fuel volume not needed by the engine takes the other path after the bowl and simply heads back to the tank to begin its journey all over again.

The biggest problem with this “dead head” design is it can cause air pockets to develop inside the fuel pathway after the bowl, and it also gives unequal flow between all the injectors. The hardest hit is injector number eight, as it’s the very last one in line, and the deadhead design can cause fuel starvation, excessive injector noise, and even premature injector wear, along with rough running, poor throttle response, low power, and overheated fuel that can turn into a sticky sludge. These symptoms can be present on a stock vehicle, but they become much more obvious and problematic when the power level is increased with a performance tune or larger than stock injectors.

Fixing the Flow

I can’t quite say why Ford or Navistar chose the deadhead fuel path, but I’d bet they didn’t think the resulting issues were a big enough deal, and it also likely came down to a cost savings argument. It would’ve only taken a few more simple parts to correct the issue, but instead, they chose to hit the ignore button. Thankfully however, during the manufacturing process, when the cylinder heads on a 6.0 and 7.3 Powerstroke were machined for the fuel pathway, the hole was drilled all the way through from end to end. They simply plugged off the end they didn’t need, but this plug is what allows us to correct the problem. All you need to do is remove the plug and allow the fuel to make a continuous loop instead of dead end, and you will see a major improvement in how the truck runs, but to correctly pull this off, you need a few parts to get the fuel where it needs to go.

Driven Diesel has been supporting the Ford Powerstroke for many years, and their Regulated Return fuel system is the perfect solution to get your 6.0 or 7.3 Powerstroke running smoother than ever. It’s a must-do modification if you plan on keeping your Ford on the road for the long haul, and it has all the lines and fittings you need to let fuel flow through the cylinder head and back into the tank. By allowing the fuel to recirculate, any small air pockets that form will be evacuated out, you get more even fuel distribution across all eight injectors, you fuel will run cooler since its constantly flowing through the head instead of sitting stagnant inside it, and because you have a steady supply of fuel, throttle response and power will both be improved. The final cherry on top is your injectors will last much longer as well.

The kits come in two flavors to suit your needs. The first choice is a simple regulated return kit that comes with the basic fuel lines, fittings, fuel pressure regulator, brackets, and everything else you need to get the job done. The fuel still flows from the tank, through the stock lift pump, and into the filter on top of the engine, but from there the stock pressure regulator inside the fuel bowl is deleted, and fuel flows straight into the engine, through each cylinder head, and out the back into a bypass style fuel pressure regulator, and from there excess fuel is routed back to the tank. If you have a stock truck you just want to increase the reliability of, the basic regulated return kit should work great for you, but if you have a modified engine or larger injectors, then you will want to choose option two.

Driven Diesel also offers their regulated return kit with a factory fuel bowl delete option, which is perfect for high performance applications because the stock fuel bowl is a bit restrictive, and by eliminating it, you improve flow further but also free up a little room in the valley of the engine, which makes maintenance and service a little easier. The only requirement to running this kit is you need to add additional filtration back into the system to protect your injectors. Usually, customers will already have a FASS or Airdog lift pump with excellent filtration built in, but Driven Diesel also offers options of their own like a filter kit that will work with your stock lift pump, a tank sump kit, and more.

Installation Overview

While a regulated return system is a simple idea, the installation can be a little involved, mainly because of the tight access to the areas you are trying to reach. Of course, the fuel bowl sits on top of the valley of the engine front and center, and a lot of the connections you will make there will be very accessible, but it’s the lines going to the front and rear of the cylinder head that can be a bit of a pain to get to, especially if you have a six-liter.

6.0 Powerstroke Install

On a six-liter Powerstroke, you’ll need to remove the air box, air filter, and intake tube, as well as both the driver and passenger side intercooler tubes. The stock feed and return line going between the tank and the bowl can stay in place, but the lines going from the filter housing to each cylinder head need to be removed and discarded. You’ll remove the regulator cover from the bowl and replace it with the provided billet aluminum adapter, but before it goes on, make sure to remove the lower poppet valve. Next, it’s time to get the fuel lines attached to the cylinder head, and this is the most painstaking part of the whole install. Driven Diesel routes the fuel into each cylinder head from the front which means it stays nice and cool before entering the engine, since its furthest away from the turbo and up pipes. The front fittings are relatively easy to access, though there are a few parts you’ll have to move out of the way. On the passenger side rear, you can access the stock fuel rail plug with the provided Allen key. It will be a pain to get to since the up pipe runs very close to it, but once its cracked loose, you should be able to easily thread out the plug and thread in the new fitting without moving any other components.

On the driver side rear cylinder head, you’ve got your work cut out for you. First, you’ll need to disconnect the exhaust manifold from the up pipe, and then wiggle the up pipe out of the way so you can gain access to the stock plug. Then, you can install the new fittings and lines, and of course, reconnect the up pipe. Once you have connections made at each end of the cylinder head, you can install the regulator and bracket, route the lines where they belong, make the final connections at the regulator, test for leaks, and then reinstall all the parts you removed at the beginning of the install. Finally, if you are installing any extras like the Driven Diesel fuel filter kit or complete engine-to-tank return line, now is the time to take care of those items.

7.3 Powerstroke Install

The installation on a 7.3 Powerstroke shares many of the steps as the install on a 6.0, but there are a few key differences. The fuel bowl is still mounted in a similar position, the feed and returns are still on the ends of the cylinder heads but accessing them is a bit different. To get to the driver side front feed, you’ll need to loosen the serpentine belt, remove the alternator, and slide the power steering pump/alternator bracket out of the way. The 7.3 also uses a check valve in the end of each cylinder head, so you need to first remove the fuel line going to the check valve, and then pull the check valve from the head. On the passenger side front, you will have to remove the AC compressor and set it aside to reach the port. One more distinct difference between the 6.0 and earlier 7.3, is the 7.3 Powerstroke uses NPT tapered threads in the ends of the cylinder heads rather than a straight thread banjo bolt, so care must be taken to not twist off or break the threads when removing the check valves, and you must use some form of thread sealer when installing the new adapter fittings to ensure nothing leaks. Oh, and don’t over tighten the NPT threads or you could crack the cylinder head. One last optional step you’ll need to do on a 7.3 is trim the stock hard lines for the feed and return to the fuel bowl or remove them entirely if you want to run new lines to and from the lift pump. Depending on which add-on kit you purchase, it may come with replacement fuel hose or JIC style fittings.

Don’t Run Away Just Yet

You may notice the fuel pressure regulator included in the driven diesel kit has a barb for a “boost reference” port which you would normally hook up to the intake manifold on a gasoline engine to increase fuel pressure as boost pressure goes up. On a Powerstroke, there is no need to raise fuel pressure with boost since that’s handled by the FICM and HPOP, but it can be dangerous to hook the boost reference port to the intake of the engine. If the diaphragm inside the fuel pressure regulator were ever to fail (however unlikely), fuel could make its way through the hose and into the intake stream, causing a runaway engine condition which may lead to a catastrophic meltdown. To prevent this from happening, simply route the included poly tube over the side of the engine away from any sources of heat and let it vent to atmosphere. This way if the diaphragm ever does fail and leak, the fuel will simply drain onto the ground instead of causing a runaway engine.

What Are You Waiting For?

Normally, I like to include a list of other modifications and upgrades to install “while you’re in there” but with a regulated return install, you don’t get deep enough into the engine to tackle any internal mods like bigger injectors or a larger turbo, and about the only upgrade that came to mind that’s related directly to fuel flow would be a upgrading to a set of High Flow Banjo Bolts on a 7.3L (6.0 Powerstroke kits already include them), tank sump, FASS or Airdog lift pump and filtration upgrade, or maybe swapping out to a set of high flow up-pipes and manifolds on a 6.0 Powerstroke since you have to loosen up one during the install. With your regulated return fuel system installed, you’ll experience a smoother running engine, extended life from your injectors, an increase in power and throttle response, and of course a happier overall engine.

How interesting that you mention what to do on a six-liter Powerstroke for installation. I want to buy a diesel truck this month and I want Powerstroke. I will find a reputable place for a 6.0 Powerstroke in my area for this.

Totally glanced over the fact that the 1994.5-1997 7.3 powerstrokes have a factory regulated return system. Only the 1999-2003 have the dead head system. Way to go.