It seems like every 20 years or so, there is a revolution in the transmission world. The Powerglide was one of the first automatics used in GM passenger cars starting in the 1950’s, and it was used through the late 1960’s in regular production models. As far as transmissions are concerned, it was about as simple as it gets. It had two forward speeds with a low gear ratio of 1.76:1 and a high gear of 1:1. If you compare that to the newest 10-speed automatics, a Powerglide’s 1st gear ratio is much closer to 4th, so you can see how some of the first automatic transmission wouldn’t do you any favors for quick acceleration. However, the super simple design and lightweight rotating assembly made the Powerglide a very popular transmission for use in drag racing applications where it is still used to this day.

As automatic transmissions increased in popularity, in the late 1960’s manufacturers began offering three speed automatics which had a much lower 1st gear ratio to improve acceleration and their strength also was raised to cope with the higher power output produced by cars of the era. About 20 years later in the 1980’s, tightening emissions standards combined with increased speed limits on the highways demanded engines be able to run at a lower RPM yet travel at a faster vehicle speed, so the overdrive automatic was born. Basically, overdrive means the output shaft of the transmission is spinning faster than the engine, and for quite some time, the four-speed automatic was the gold standard. It had a wide enough gear spread which would help with acceleration from a dead stop while still allowing a comfortable engine RPM at highway speed, but one of its drawbacks was the large drop in RPM between gear shifts.

In most American vehicles, the four speed auto was used heavily up until the early 2000’s, but manufacturers saw the need to develop a transmission with more gears spaced closer together, but this time it took a while to perfect the design and operation because the number of moving parts increased dramatically with each gear added. Between roughly 2005 and today things have taken off, as there have been a few 5-speeds, a bunch of 6’s, a handful of 8-speed autos, and today, the magic number of gears seems to be 10, and in another couple years, who knows where we’ll be. I’m sure the designers of the first automatics back in the 1950’s had no idea their transmissions would ever grow to the point of having six or ten speeds, but they could surely appreciate the machinery required to manufacture these modern marvels, and the benefits they give. With so many gears spaced so close together, the engine is allowed to stay near its peak torque which means greater acceleration with less RPM loss between each gear, and this benefit can be applied directly to a diesel pickup truck.

A Match Made in Heaven

When GM introduced the LB7 Duramax back in 2001, they had a few choices for the automatic trans which would be attached to it, and their strongest in-house design at the time was the 4L80e. It was a four-speed normally found in ¾ and 1-ton applications, and it came behind everything from the 4.3 V6 to the 8.1L gas V8 and was even used with the GM 6.5L Diesel. Because of its shared heritage and strength, hot-rodder’s refer to it as a Turbo 400 with overdrive, but it wasn’t quite up to the task of working with a full powered Duramax, although they did use the 4l80 behind a de-tuned version of the Duramax in the Express Van for a few years. Instead, GM turned to their partner Allison for a transmission to use in their HD pickups, and the option they settled on was the A1000 which was normally found in busses and garbage trucks. The A1000 was much stronger than any competitor’s transmission at the time, and when you combined that with the first (in a pickup) common-rail V8, GM was sitting on top of the mountain while Dodge and Ford were still sitting down at the base camp. With a first gear ratio of 3.094:1 and an overdriven 5th gear of 0.711:1, the Duramax will pull with the best of ‘em and cruise down the highways with relative ease, but when GM introduced the six-speed Allison in 2006, owners of 2001-05 trucks certainly felt the cold shoulder of progress.

There were many reasons why GM chose to switch to a six-speed, chief of which includes a lower RPM at highway speeds, which helps reduce fuel consumption, but that also leads to less wear and tear on the engine due to the lower RPM. There’s no doubt the extra forward gear gave the LBZ and newer trucks a huge advantage over the LB7 and LLY, and you wouldn’t be faulted for thinking the 6-speed Allison was an all-new transmission. With a little research, the first thing you might notice is the fact that first through fifth gears have the same exact ratios between the five and six-speed, but surely there are many other differences, right? If you get a little more in-depth, you’d notice other parts like the pan, filters, and torque converter all will interchange as well, and the cases look visibly identical. As it turns out, aside from a few minor tweaks to fluid routing, clutch return springs, and pistons, the two transmissions are basically identical inside.

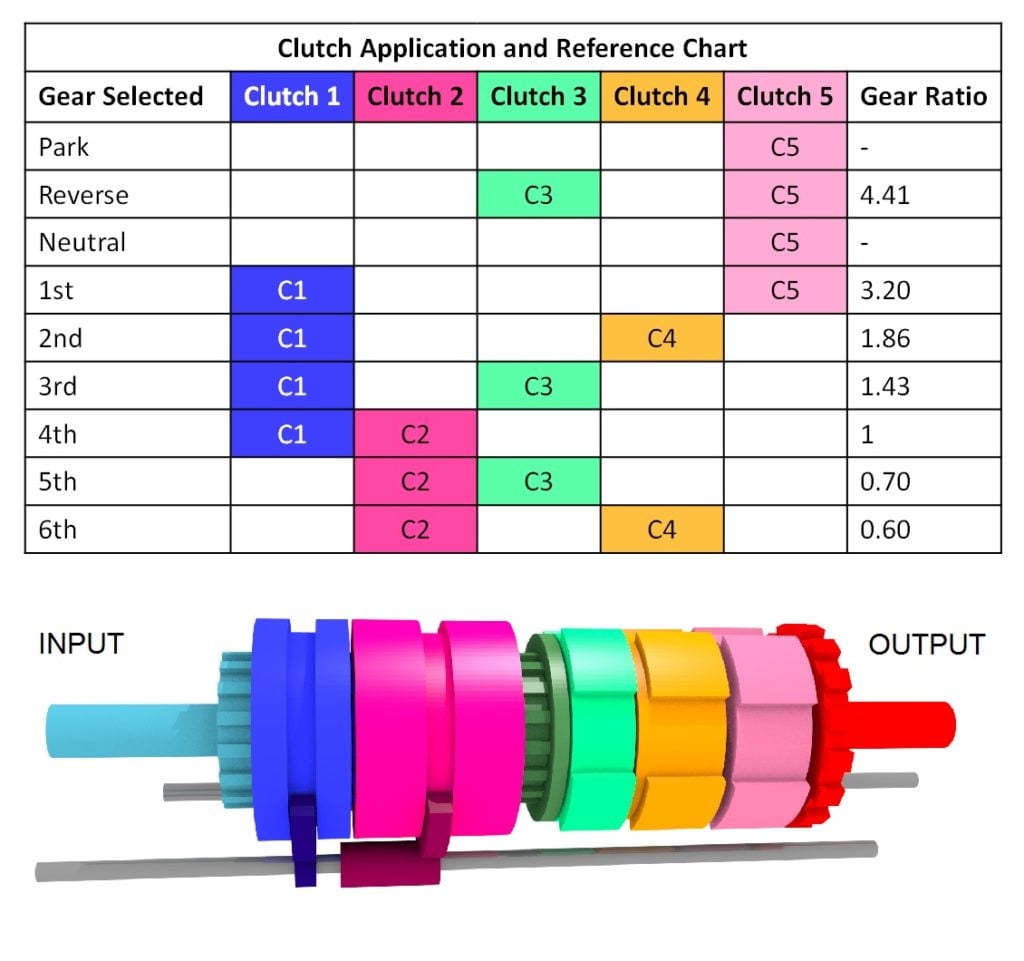

Every five and six-speed Allison 1000 has a rotating assembly which is made up of five individual clutch packs designated C1 through C5. Whenever the TCM engages or disengages different clutches at the same time, certain planetaries are allowed to spin or remain stationary which is what creates the different forward gear ratios. If you’ve seen an Allison torn apart on a bench, you’d likely be scratching your head trying to figure out how it all fits inside the case, but all you really need to know is how it works. In first gear, C1 and C5 are engaged, second gear uses C1 and C4, and each forward gear and reverse has its own clutch combination. Even though the rotating parts are essentially identical, the one major difference between the five and six-speed Allison is the valve body. The 5-speed version didn’t have the appropriate solenoids and fluid passageways required to engage C2 and C4 at the same time, which is how you get the 6th forward ratio 0.614:1. At first you might think you could just grab a valve body from a junkyard and throw it into your transmission and go, but it’s a bit more complicated than that. First of all, the TCM hasn’t been told you want to shift into 6th gear, and there are a few other small changes required which make a DIY swap difficult.

Highway Tunes

You surely have heard of Duramax Tuner by now, as they are a leader in the Performance Calibration industry and specialize in emissions intact diesel tuning. Duramax Tuner also offers some of the hard parts required to get the most out of your diesel, and if you are rocking an LB7 or LLY with a 5-speed Allison, they can help you unlock the hidden potential inside your original transmission. Their Six Speed Conversion Kit comes with everything you need for a plug and play installation, and will enable 6th gear just like the 2006 and later trucks. The kit is made up of two parts, first of which is a valve body with all new solenoids and the internal wiring harness attached, but the most important part of the conversion is the Transmission Control Module (TCM) which allows the five speed to function as a six. The Duramax Tuner TCM comes tuned for your specific truck, and will account for changes to tire size, gear ratio, and engine modifications, to provide a smoother shifting transmission with optimized shift points which greatly improves the driving experience. They can command the torque converter to lock up sooner, allow a downshift with less throttle input, and a whole myriad of other adjustments which help get your engines power down to the ground.

Simply by shifting from 5th into 6th, your engine RPM will drop by 14%, and while that may not seem like a lot, at a speed of 80mph it will bring the engine speed down from 2,260 to 1,941 RPM, and the faster you go, the greater the RPM drop will be. We already talked about the bump in fuel mileage and decrease in engine wear, but perhaps the most welcome feature of a 6-speed conversion is the reduction in noise inside the cabin, which is a huge deal if you use your truck for longer distances.

Bolting it Together

It’s true that automatic transmission work scares a lot of people away, but a valve body swap in an Allison is really child’s play, and all you need are some basic hand tools and a bucket. Once all the fluid is drained out and the pan is removed, the filter simply pulls out of the pump, and then 15 bolts are removed which hold the valve body into the case of the transmission. Thankfully, you don’t even have to worry about the tiny steel check balls falling out or springs flying through the air because all the small parts are captured inside. Once the old valve body is removed from the transmission, the new one installs in the same exact place using the original hardware. Under the hood, all you need to do is disconnect the stock transmission control module which sits on the fan shroud, and plug the new one in its place, and once the truck is on the ground with the fluid topped off, you can operate the truck how you normally would, except now you have another gear available.

The best part of the DuramaxTuner conversion kit, is it will allow your Edge Insight CTS2 to display the current gear including 6th, which is a feature missing on some other kits, but to truly operate like a factory 6-speed truck, you’ll need to be able to manually select the gear you want: happily, their kit is also compatible with the same TapShift Conversion which worked on your 5-speed Allison without any hiccups.

While You’re in There

The installation of a 5 to 6-speed conversion is a perfect opportunity for a few more upgrades at the same time, since you already have the trans apart. I would strongly recommend you throw on a new set of filters to make sure the small passageways and solenoids inside your new valve body are protected from any contaminants in your fluid. Luckily, the Allison uses a pair of filters: one inside the pan, and an external spin-on filter. While it may be overkill, I always recommend replacing the spin on Allison filter every other engine oil change to keep the fluid and internal filter much cleaner, and a great insurance policy is the PPE Double Deep Transmission Filter. It will trap particles down to 15 microns in size which is incredible for a transmission filter, and it has almost three times the surface as a stock sized filter, which improves oil flow and will result in a cleaner, smoother shifting Allison.

Because you had to remove the trans pan for the swap, this is also a great chance to lower the temperature of your fluid and increase the capacity all at the same time by installing a Deep Transmission Pan from Mag Hytec when you put it all back together. It will hold an extra 4.5 quarts of trans fluid over stock, and the finned aluminum design will help the transmission shed heat from the fluid a lot quicker. Speaking of fluid, it’s also a perfect chance to pour in some fresh ATF, and swapping to a premium fluid like Schaeffer’s All-Trans Supreme will help the fluid run even cooler than before, but it will also withstand the harsher conditions often seen inside a diesel transmission when subjecting the truck to heavy towing or higher horsepower.

What Are You Waiting For?

Right now, the LB7 and LLY Duramax powered trucks are getting more popular than ever and they are becoming much more affordable as well. They were produced before major emissions control devices were installed which makes them more desirable, and they have a classic body style with good looks to boot, but as great as the Duramax is, it can be hard to live with the higher RPM of a 5-speed.

The good news is you already have all the parts needed to run the truck in 6th gear, it just requires getting your hands a little oily to swap a valve body and throw in a TCM which can control it all. The trial and error has already been done for you, and as soon as you take your Duramax out for the first test drive, you’ll immediately notice the RPM drop between 5th and 6th gear, and because it’s now so much quieter inside the truck, you’ll have plenty of time to think about the worlds bigger problems like why anyone would eat blue cheese on chicken wings or which Disney villain you look most alike.

If I get a reman 6 speed allison for my lly duramax (cause my a1000 5 speed needs to be either replaced or rebuilt) could I just get the TCM instead of the valve body? Cause in my situation it seems more cost effective to get the transmission that already has the valve body. Is there anything else different that would keep me from putting the six in instead of converting the 5?

That’s an excellent question, but we haven’t attempted the swap ourselves. That said, I’m inclined to say no. Everything would bolt up the same with the exception of the cooler lines, and the NSBU switch as LLY’s are mounted on the outside of the transmission and 2006+ 6 speed units are inside. After doing a little research, it would not work, plus the issue of returning your core and most would not accept the change between what you’re purchasing versus what you’re returning, or would typically at least not give a full refund.

I have an 01 2500HD with the 8.1/Allison. I am interested in this conversion if it is something that I can do. Do you offer this for my application?

Hi there, and thanks for the question. In THEORY, the DuramaxTuner 5 to 6 Speed Conversion Kit would work in your 8.1L. That said, they have yet to get their hands on a truck such as yours to be able to confirm fitment. So, we couldn’t confidently say “yes” this will work, only in theory. Maybe get a hold of DuramaxTuner direct and see if they’d be willing to work with you to see if it would work?

If I understand you, I can take an Allison transmission from my 2006 Duramax Chev 2500 and install it in my 2003 GMC Duramax Diesel providing I install the proper TCM?

Unfortunately, its not quite as easy as that as there are other differences than just the TCM. For this swap, you would need to change the valve body, internal harness, bellhousing with input sensor, and install an external NSBU (Neutral Safety Back Up) to make this particular conversion work.

So I have an 05 LLY and all I have to buy is the valve body and TCM for the conversion? Then if I wanted to just get the whole thing buy the upgraded stuff like shifter, deeper pan, filter, and fluid right?

Being a transmission builder, I have an 06 valvebody I can use. Can I purchase the internal wiring harness and tcm from you and it still work?

Hello, I have a 2003 Ford F650 with the 5.9 Cummins and a Allison 2400. Will this work for mine?

Does this 6 speed conversion work on the a 2005 Allison 2000 series 5 speed