Turbocharging is a common method used to increase the power output of all types of internal combustion engines, and they work by utilizing free energy from your engine’s exhaust. In the eyes of gearheads everywhere, turbos are the single greatest invention known to man. A turbocharger is an extremely precise piece of equipment that spins at very high speeds while operating at insanely warm temperatures, so it’s natural to wonder exactly how long they can last on your engine. The average turbo will see temperatures in excess of 1,500°F on a regular basis, will spin at close to 100,000 RPM, and can move several hundred cubic feet of air every single minute. Knowing the harsh conditions that a turbocharger lives in, it’s a miracle that turbochargers work at all, but surprisingly they last a lot longer than you might expect: however the million dollar question is how long will your turbo last, and what happens when it fails, and is there anything you can do to make it last a little longer?

How Long Do Turbos Last on a Diesel?

Turbochargers can be used on any internal combustion engine, whether it runs on gasoline, ethanol, methanol, natural gas, diesel, nitromethane, propane, or pretty much any fuel that can combust. Some people have even hooked up a turbocharger to a wood burning stove, but because each fuel burns at slightly different temperatures, each type of engine can place different amounts of stress on a turbocharger.

Probably the most common application for a turbocharger is the diesel engine, since they come in semi-trucks, pickups, heavy equipment, generators and more. Diesel engines operate at a relatively low engine speed compared to gasoline engines which can help to extend the life of the turbocharger, but on the flipside of the coin, the turbo on a diesel engine will produce much higher boost pressure than on a gasoline engine. Most stock turbocharged gas engines will produce somewhere around 10 PSI of boost pressure, where most stock diesel engines run somewhere around 30 PSI, and if you turn up the power with a programmer, the boost pressure only goes up from there. Thankfully, as long as proper care and maintenance is performed, a turbo can last for a very long time on a diesel truck.

How Does a Turbo Diesel Work?

To understand how a turbocharger works on a diesel engine, you first must understand how the internal combustion process works. All modern diesel engines use a 4-stroke or 4-cycle design, which means there are four basic steps to their operation, and the combustion process begins as the starter motor turns the engine over. Each piston will travel downward in its cylinder, and when the intake valve opens, a fresh charge of air is drawn into the engine. This is the first of the four cycles, and it’s called the intake stroke. As the crankshaft continues to turn over, the piston is pushed upward, but now all the valves will be closed and this will squish the volume of air that’s been drawn into the engine (compression stroke). According to the laws of physics, the act of compressing the air will result in a rapid rise in its temperature, and once the piston reaches the top of the stroke, fuel will be injected into the high temperature air which will cause it to immediately ignite. The rapid expansion of the burning fuel will push the piston downward (called the power stroke) which is what makes the engine run. Once the piston reaches the bottom of its stroke, the exhaust valve is then opened up, and as the piston travels back upward, all the spent air and fuel will be forced out of the engine and into the exhaust manifold, and ultimately out the tail pipe. When the engine is running at its normal speed, there are thousands of exhaust pulses leaving the cylinders every minute, and on a naturally aspirated engine, that exhaust energy simply goes to waste, but a turbo allows you to recapture that energy and put it to use to make more horsepower.

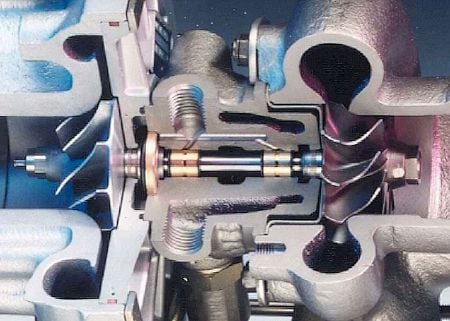

A turbocharger consists of two halves, and the first is called the turbine. After the exhaust gas exits the engine, it is directed into a cast iron turbine housing and through the blades of the turbine wheel, and because of the velocity of the gasses, the wheel will turn at a very high rate of speed. Attached to the turbine wheel is a shaft which is supported by either a ball bearing or a bronze bushing, and depending on the model of turbo, the shaft speed may range anywhere from 60,000 RPM all the way up to 120,000 RPM. The bearing or bushing receives lubrication from pressurized engine oil that’s pumped into the top of the turbocharger, and excess lubrication drains from the turbo back into the bottom of the engine. In addition to lubricating the shaft, the oil also helps regulate the temperature of the turbocharger, but many manufacturers also circulate engine coolant through the center section of the turbo to keep temperatures even cooler.

On the opposite end of the turbocharger shaft is another wheel that looks similar to the turbine, but this time it’s called the compressor and it has a very different job. The compressor section of the turbocharger draws in fresh air from the atmosphere, raises its pressure, and forces it through an intercooler, through some tubes, and ultimately into the engine. Because the turbo crams extra air into the engine, each cylinder is filled with much more air than it would naturally be able to draw in, which means more fuel is allowed to mix with the increased amount of air which results in a bigger explosion and ultimately more horsepower.

What’s the Average Turbo Lifespan?

So let’s talk real-world numbers: how long will the turbo on your diesel truck last? Of course, the answer depends on how the truck is used, how the engine is maintained, and whether or not the engine is operating correctly, but a turbocharger on a diesel engine will usually last for at least 150,000 miles, but more often than not, the average turbo will still be functioning correctly at 200,000 miles, and there have been numerous examples that continue to operate well beyond that. The next logical question though, is how do you make sure your turbo lasts as long as possible?

Turbo Maintenance to Extend Lifespan and Improve Performance

Just like with any mechanical system, in order to get the most life out of your turbocharger, proper care and maintenance is key. Because of how fast a turbocharger can spin and the toasty temperatures inside, proper lubrication is essential to a long-lasting turbo. The first step to ensuring you get an extended lifetime of service from your turbocharger is making sure your engine oil is changed at the proper intervals and that you use a high quality oil like Schaeffer’s 9000 Synshield OTR Plus. A premium oil will provide better lubrication, better resistance to heat, and will allow for extended drain intervals. Next, you’ll want to make sure you also use a premium oil filter on your engine, so if any dirt particles do make their way into your oil, they will be trapped before they can do any damage to the turbo, bearings, or any other moving parts inside your engine. For a great oil filter for your turbo diesel, you should check out PPE. They sell High Efficiency engine oil filters that can trap dirt as small as 5 microns in size, but they also won’t restrict the oil flow throughout the engine which means cleaner oil, and unrestricted lubrication flow throughout your engine.

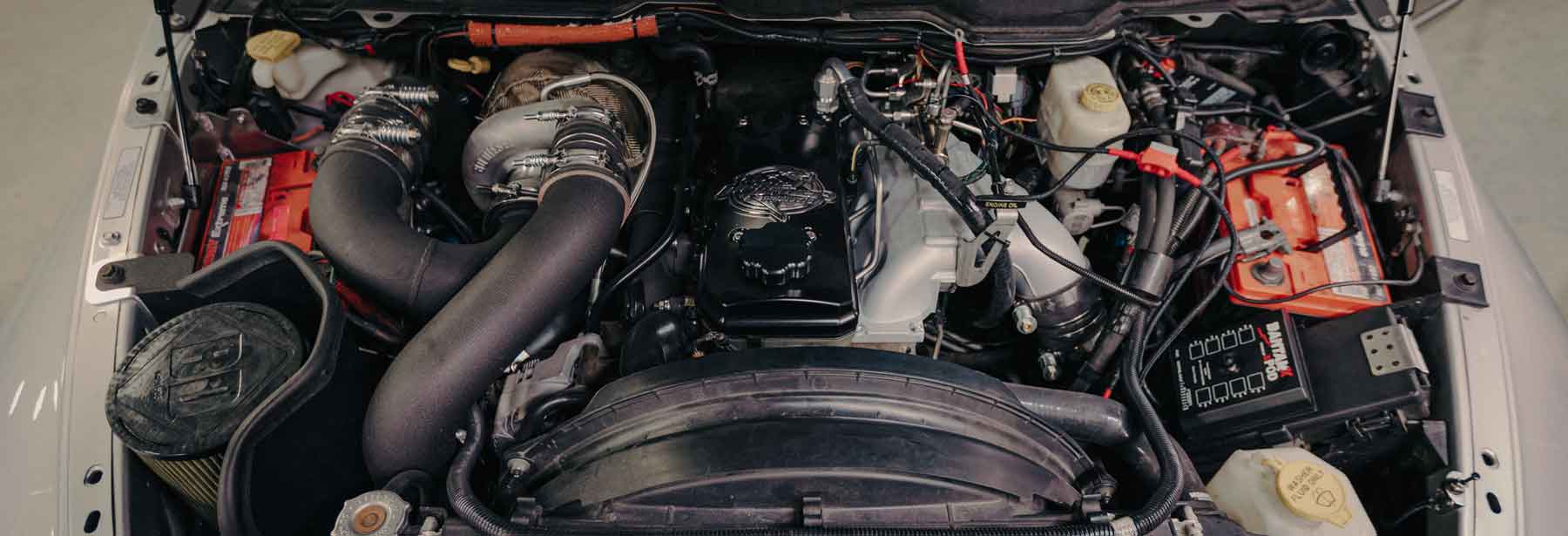

The next step to ensuring your turbocharger lasts a long time is cleaning the air properly before it’s allowed to enter the compressor section. This means making sure the air filter is clean and free of debris, but an extra benefit can be had by also allowing cooler air to enter the turbo. A quality Cold Air Intake from S&B will make sure cool ambient air will enter the turbo instead of hot air from the engine bay, and as everyone knows, cooler air is denser, which also means a slight bump in power as well.

Finally, there are some good driving habits you should keep in mind that can help extend the life of your turbo, and they mainly have to do with temperature control during the first and last minutes of your drive. When you start your truck up in the morning, let the engine (and the attached turbo) slowly come up to operating temperature before you use heavy throttle. This doesn’t necessarily mean you have to idle the engine for 20 minutes before driving at all, but rather you should drive gently until the engine is fully up to temp. Once the engine is warmed up, you can use as much throttle as you wish, but more important to turbo longevity is the last few minutes of your drive. The worst thing you can do to a turbo is shut the engine off immediately after a hard acceleration run. If for example you are climbing a steep grade with a trailer on the back of your diesel truck, and you want to stop at the scenic overlook at the top of the mountain, do not pull over and immediately shut down the engine. At full load, exhaust gas temperatures can be over 1,500°F, and because your turbocharger is directly connected to the exhaust system, the turbine wheel, shaft, exhaust housing, and the oil inside the turbo are all going be extremely hot. When you shut down your engine, oil and coolant are no longer flowing through the turbo, and the heat inside the turbo can “cook” the remaining oil on the bearings and shaft which will turn it into a sludge which can restrict oil flow, but also can act as an abrasive which will greatly reduce the lifespan of parts inside your turbo. Instead of a quick shutdown after a steep climb with your diesel engine, just let it idle for a few minutes to continue circulating oil and coolant through the turbo which will allow it to cool off properly. If you must exit the vehicle right away but still want to let the turbocharger cool down properly, Turbo Timers are a great accessory that can help extend the life of your turbo. Turbo Timers are available from BD Diesel and Edge Products, and once installed, they will allow you to remove the key from the ignition and lock the doors of the truck, but still let the engine continue to run for a predetermined amount of time until the turbo properly cooled down.

What are the Symptoms of a Bad Turbo?

Despite your best efforts to prolong their life, all parts will eventually fail, and turbochargers are no different. But how will you know when a turbo is on the way out? Some part like a timing belt will give zero warning before they fail, but a turbocharger will give you plenty of heads up that it’s on borrowed time, as long as you pay attention. Your truck can feel less powerful than before, you may see a check engine light come on with a code for low turbo boost, or you may hear some whining or grinding sounds.

When a turbo does fail, usually the problem starts inside the center section when the bearings or bushings start to wear out and will no longer keep the center shaft properly located. Because of the extremely tight tolerances inside the turbo, if excess shaft play does occur, the compressor or turbine wheel may come into contact with their respective housings, and if that does occur, immediate damage will result to the wheel. It may not be catastrophic damage, and usually just the tip of the blade will wear away or break off, but this will result in a further loss of performance and an imbalance which will cause additional wear on the bearings/bushings and some extra noises that will be difficult to ignore.

One easy way to tell for sure the turbo is unhappy, is to simply pop off the air intake tube and take a look at the compressor wheel. Carefully inspect the tip of each compressor blade for damage, and then grab the center nut and wiggle the shaft back and forth. Any excess play will be evident, and if the compressor wheel can contact the housing, chances are the turbo is past its prime.

Shop Turbos at DPP

If you find yourself with a turbo that needs to be replaced, there is only one place you should go to get a replacement. Diesel Power Products has every kind of turbo you could need for your diesel truck, so whether it’s an OEM replacement for a Duramax or an upgraded turbo for a Cummins, or anything in between, DPP has what you need. They have experts available to answer your questions recommend the correct turbo for your needs, and they can ship you out a turbo in no time to get your diesel back on the road.

I have a 2019 Ram 3500 DRW with Cummins HO Aisen 4.10 that I use for hotshot and pulling a 5th wheel RV. I have installed every possible banks component and now at 126K miles, I am getting CEL with code P226C. Turbo boost seems to intermittent, so I feel like I am needing to replace it. What do you suggest? Not looking to increase power necessarily- just wanting to make engine efficient and last.

Most things like cool down and oil, I knew. What I did not know was what to look for when the turbo may be getting bad.

I have a stock 2001 Dodge Ram 2500 cummings HP245 hp. I have 265,347 miles and the only change is my fuel system upgrade with a new pump and fuel and water filters, change them every 50,000 miles and really don’t drop much below 1/2 tank of fuel. Not sure about a upgrade turbo cause I drive with loads over the CA mountains and was told not to get a bigger turbo??? Thank You…William

The good news being your truck is the HO version so presumably with the 6 speed manual would mean you have the Holset HX35 turbo, as opposed to the smaller HY35 found on automatic transmissions. Now, you’ve got quite a few miles on the original turbo. I’d recommend at the least to remove the boot on the intake side of the turbo (coming from your airbox) and with the engine off, “wiggle” the shaft that the compressor wheel is bolted to and see if there’s excessive play and verify there’s no rub marks on the inside of the housing. On a stock truck, no, you don’t “need” an upgraded turbo, but towing in higher elevations and probably with some warmer ambient air temps, a small upgrade could prove beneficial in keeping temperatures down and add some power. No, you definitely never want to go too big of a turbo, it should always match up to your fueling. Now, if you do even have a performance chip or a programmer, at that point it would really be beneficial to upgrade the turbo.

If you do find that you have excessive shaft play but would prefer to rebuild your existing turbo, we have both rebuild kits as well as pre-built cartridge assemblies from Rotomaster you can check out here:

https://www.dieselpowerproducts.com/c-125-1994-02-59l-dodge-cummins-turbo-accessories.aspx#/filter:cfm_manufacturer:Rotomaster

And to check out any other turbo upgrades or accessories we have for your truck, you can see those here:

https://www.dieselpowerproducts.com/c-125-1994-02-59l-dodge-cummins-turbo-accessories.aspx

Finally, if you have any questions or want to shoot us some pictures or even a video of how much turbo shaft play you have, feel free to respond here so send an e-mail to [email protected]

Great article and info. Will respond more later. Thanks