We get a lot of calls on a daily basis with customers trying to diagnose some type of issue with their truck. Fortunately, we’re typically able to help diagnose and give recommendations for products or procedures to remedy the issue. We must have developed quite a name for ourselves over the years, as frequently we even get calls from shops that are scratching their heads, hoping we have the golden ticket, and fortunately, we usually do! One of the most common calls we get are from customers with a 2003-2007 Cummins that have developed either a hard start or no start condition. In order to help out, we had our very own Tyler Lucas, put together this step by step tutorial that you will hopefully find insightful. Tyler has been elbow deep in diesel engines for years, especially Cummins, so he is a wealth of information when trying to cure a plagued engine.

The very first thing that needs to be checked is battery voltage. When I say battery voltage, I am not talking about just getting a voltmeter and putting it on the positive and negative posts, as you will only get what’s called a surface charge, which won’t tell you what’s actually going on when the battery is under load (i.e. cranking). It is very common to have a battery read around twelve volts on a surface charge, but then drop well below nine (the minimum voltage to allow for cranking on 2003 to current Cummins) when under load. Overall, make sure that when you test the battery, you are doing so under load by cranking the engine and watching the voltmeter.

Let’s now say your batteries are good. You then ask yourself, “Tyler, what now?” Don’t worry sad no start truck, we’ve got your back! Let’s now dive into the fuel system. First off, let’s get this out of the way, Ram trucks NEVER had the best luck with lift pumps. A lack of lift pump flow will not only cause a no start issue, but depending on how it failed, can cause other issues that we will discuss further into this post. The factory lift pumps on the 2003-2007 Cummins produce a dismal 10-11.5 PSI at idle. But unfortunately, due to these pumps’ inability to actually produce volume, the pressure drops off considerably as load increases. And remember, while pressure is definitely an important factor as this is the rate at which fuel is dispensed, volume is equally, if not more important, as it’s the amount of fuel. This drop in pressure is even greater when fueling modifications and upgrades are added, such as programmers, upgraded larger displacement injectors, and higher volume injection pumps, because guess what, they are all demanding additional fueling for increased performance. When you start going below 5 PSI, you are not supplying the injection pump with enough fuel to properly drive the injectors, and at the very least, you will experience a loss of power and fuel economy. Some customers will notice the truck “falling on its face” or flat lining with power as the pump simply cannot supply any more fuel. After time, the pump will just stop working due to being over stressed and constantly running at maximum output. And this is exactly what we will be testing for next, the health of the lift pump. The best way to check your fuel pressure is to install an inline pressure gauge before the injection pump. But we understand that in many instances when your truck won’t start, you simply don’t have the time or resources to collect the parts and tools to accomplish this. So we have an alternative method for you by checking the general volume output of the pump. In order to do this, remove the fuel supply line before it connects to the injection pump and place the open end into a bucket under the truck. Next, hop in your truck, and “bump” the key. When I say bump the key, just turn the key to crank the engine for a second in order to engage the pump. At this point, you should hear the pump run the duration of its cycle. For reference, the 2003-2004.5 trucks came equipped with a block mounted lift pump and the 2005-2007 trucks came from the factory with an in-tank lift pump, yet many of the 2003-2004.5 trucks were later retrofitted with this same in-tank design. This will give you a gauge on where to listen for the “hum” of the electric motor on the pump. Once you’ve bumped the key, presuming the pump is operating normally, you should see fuel dumping into the bucket. However, if no fuel comes out, then it’s safe to assume that this is the culprit of your no start issue. In order to correct, you’ll need to replace the lift pump, and no better time to upgrade than now. Our preferred brands of aftermarket lift pumps are FASS and AirDog, simply because they have options for stock to fully modified engines, offer filtration that is far superior to stock for increased protection, and come standard with a lifetime warranty. Out of those manufacturers, our most popular models are without a doubt the FASS Titanium and AirDog II-4G. For most trucks, even slightly modified, a volume of 95 or 100GPH is ample to properly supply the injection pump for a lifetime of trouble free service. And just remember, bigger isn’t always better in terms of lift pump choice.

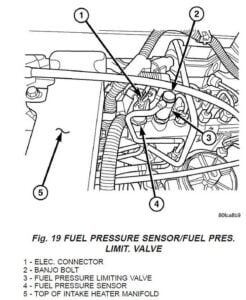

But Tyler, I checked that and everyone knows that Dodge lift pumps are sub-par at best. Stay with me here, we are graduating to the high pressure side of the fuel system now. One of the most common problems I see on common rail Cummins, is the pressure relief valve, or PRV for short. For those unsure of exactly what I am talking about, this is the large fitting on top of the fuel rail that has a fuel line attached to the top of it via a banjo bolt that then returns fuel back to the factory fuel filter. The pressure relief valve is designed to do just as the name implies, relieve pressure. Specifically, it begins to open at 26,000-27,000 PSI and return any excess fuel to be recycled back into the system. Commonly, these valves will get stuck in the open position and stay that way when the truck is turned off. If the valve is stuck in the open position, the truck is unable to build the necessary fuel rail pressure (5,000-7,000 PSI) for startup. Remember, this is a common rail system and that pressure is absolutely necessary for the fuel to be atomized properly to create combustion. To visualize this, imagine trying to blow up a balloon with a gaping hole in the side of it, not happening, right? In most cases, we sell either a new replacement pressure relief valve to return the system to stock, or a PRV Block Off to eliminate the relief valve all together.; Some would argue that installing a block off is unwise when combined with a factory fuel system because it cannot protect itself against pressure spikes. Now, I have been around these engines quite a bit, and have installed countless block offs in completely stock trucks without a single issue. This fuel system is designed to handle exceptionally high pressure, so a small spike in pressure for .00001 of a second should not cause any damage. The benefit of installing a block off as opposed to a new PRV? Well, that’s simple; number one you’ll never have to worry about a blown PRV again, and secondly, a block off is substantially less money. With that said, I don’t recommend running a stock fuel system with a rail pressure box, such as the TS-MP8 on its max setting, combined with a block off, as it will over stress the fuel system. Which one is right for you? That’s up to you and your truck, but as always, if you need guidance, feel free to contact us and we will help steer you in the right direction.

Before we go to another portion of the fuel system, another quick check is the transfer or connector tubes. This is the part that transfers fuel from the high pressure common rail to the injectors. The fuel line from the rail connects to the inlet and is seated against the injector via a jam nut. There was actually a TSB (Technical Service Bulletin) from Dodge years ago regarding the tubes losing torque, causing them to leak between the injector and the tube. This can easily be checked by removing each individual fuel line and checking the jam nut to ensure it has the proper torque. I torque tubes to around 55 ft. lbs., factory spec is 35 ft. lbs.

Now you may say, “guess what Tyler, I’ve already checked that, what’s next on the docket?” Well fellow Cummins connoisseur, I have your back yet again. This next test gets a little more involved. Each of the six injectors in your engine will return fuel. The maximum amount of leakage on a warm engine is 160 mL per minute at about 1200 RPM’s. During cranking, you want to see 90mL, or about the amount of fuel that would fit in a double shot glass, essentially not a lot of fuel. In order to perform this test, you will need that trusty bucket yet again to capture the return fuel, as well as a small section of hose that will be used to extend the return line somewhere where you can watch and hold the bucket. If you look in the driver’s side front fender well, there are two hard plastic fuel lines with a clip attaching them about halfway up the engine. One is a return from the CP3 injection pump coming out of the fuel filter canister, and the other is for the injectors coming from the back of the head. Make sure you are only dealing with the line coming from the back of the head. You will take that line and detach it by releasing the clip. Now that the return line is free, attach your hose to extend into your trusty bucket. Finally, have a helper hop in the truck and start cranking. Unfortunately, this particular test requires you to crank the engine for an entire minute, which will seem like an eternity to you, your starter, and your batteries. Being the spec is only 90mL, if you have gone past that in the first 15 seconds, just stop, as we know there is a problem at that point. Usually a good working set of injectors that are returning the proper amount of fuel will just lightly trickle out of the return line. Any result over 90mL means the injectors are returning excessive fuel, and they either need to be repaired or replaced. This is also a great test if you have lost fuel economy, but the truck seems to be running properly. A slight drop in injection pressure caused by excessive return will cause improper atomization, therefore decreasing efficiency. That’s another topic I’m sure I could elaborate on for a few pages about, but that’s for another day!

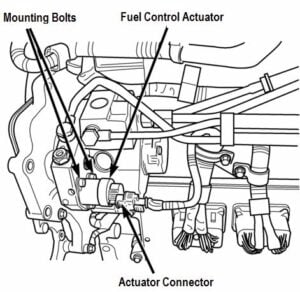

If you have checked everything and we still have a no start condition, I would look at the CP3 injection pump. The only way to really test the output of the CP3 is to send it to a fuel shop and get it on a test stand. There is one test you can do at home, but it is definitely a backyard mechanic test, and not a true determinant for the health of the pump. We will be looking at the Fuel Control Actuator, also known as the FCA, M PROM, and I have even had people call it a pressure regulator. This is the two wire actuator coming off the back of the CP3, and is the only electronic connection on the pump. This sensor basically tells the CP3 what pressure it needs to be at. In some instances, this actuator will either get stuck in a certain position or stop operating altogether. When this sensor is unplugged, the pump loses its ability to restrict flow, thus will run at maximum pressure, which is exactly how we will run this test! We are going to unplug the FCA and attempt to start the truck. Keep in mind you Cummins techs out there that say this is not a valid test, as this test is not for you. This test is for the hard working Average Joe that doesn’t want to take his truck to you and pay your $120 per hour labor rate. Alright, now back to the test, if the sensor is unplugged and the truck starts, we can assume the sensor is not functioning properly, which again, is a very commonly failed component. Now very important, if the truck starts, make sure you quickly turn it off, as with the FCA unplugged, there is no metering of the CP3, which means it will run at maximum capacity, causing elevated RPM’s and a rough idle.

All of the above tests are intended for the do-it-yourselfer, and will typically lead to the underlying cause of the issue in most instances we have encountered. However, if after performing these tests the diagnosis is still uncertain, the problem is probably more in-depth. As always, if you have any questions about the above information or any of the products mentioned, do not hesitate to give us a call or send an e-mail to [email protected] and we would be happy to assist.

Tyler Lucas

Assistant Sales Manager

(888) 99-DIESEL Ext. 103

Great information. I am going to share with my students.

What do I do when I still have no fuel out the high side of the CP3 Ive taken the line off and there is no fuel while cranking. I am getting slight pressure out the return fitting when I crack it open. With the lift pump running.

Any advice would be great.

Thanks Sam

With all the lines connected, if you unplug the FCA, will the truck fire? Unplugging the FCA should make that pump go to max pressure. You may have an issue with the pump itself.

Sam, I am having the exact same problem and was wondering if you ever got it figured out. Any info would be good.

Nice write up Diesel Josh. The one thing that I would add as I have been faced with this is when you have a condition where the cranking RPM falls below the threshold of what I believe to be 150 RPM, (measured with a scanner) assuming CP3 Pump works fine and injectors do not leak over the threshold (either via the connector tubes which is measurable via the return or the injector tips). If one is not able to start the truck due to lower than 150 RPM which I believe to be the minimum cranking RPM, however when plugged in the engine is easier to turn and the RPM goes over 150 and the engine starts then one can rule out the fuel delivery, including injectors, CP3, lift pump etc. This is where one wants to suspect the electrical delivery such as the week batteries or starter and wires. It does not meant that fuel delivery is optimal as the additional cranking speed may be required to bump up the rail pressure to the minimum requirement however this would only be seen in borderline situations. All I know is if a truck starter can’t produce 150 RPM then that’s the first thing to fix before looking at fuel delivery.

Thank you for taking the time to do such a great write up.

Thanks so much for the response on the write up. And yes, you are exactly correct that you at least need to have adequate charging and cranking speed in order to initially fire the engine. Great response and additional information, thanks again.

Hi, thanks for the very informative article.????

But just to be sure, if my truck starts fine after being plugged in for three or four hours than that rules out fuel delivery as a possible cause?

I’ve replaced one of my grid heater solonoids and checked the other one and it works. I’ve also cleaned all of my connections and the grid heater seems to test fine and heats up to some extent (not sure how hot it’s supposed to get) but my truck is still hard to start at temps under 70f unless I plug it in.

Any suggestions would be appreciated. ????

So I cap the #3 injector at the rail and it will start. I reconnect the injector line and it will start. If I do not cap it off and leave the injector line alone it will not start no matter how long you crank. I put on new injector line. Same issue. Makes no sense to me..

Well if you cap # 3 and it starts, and when fuel is allowed to flow to that #3 Injector it doesn’t, its more than likely returning to much fuel to where it is dropping rail pressure enough to not fire the engine. I would move #3 injector to another hole and see if the problem moves to that hole. If it does then you know you have a bad injector.

nice write up, have done everything in your article still no start, have a 09 6.7 with low km truck just quit on the hwy. new lift pump new injector pump new crank sensor. will crank all day lots of amps. no codes on the dash ( engine light will flash, have a lift pump gauge not working no other codes) I have a delete kit that was installed yrs ago no issues. After trying everything no luck now I know what your going to say but I tried a sm squirt of either engine fired right up but would only run when throttle was 1/2 or greater will stall when i let it try to idle. Is there a sensor somewhere that controls the fuel on start up? Any help would be appreciated .

I have a 2007 dodge Cummins 6.7 6speed..terminals went bad but would still push start easily..changing out terminals a wrench arched the grid heaters solenoid and has not fired up sense..any ideas would be greatly appreciateed

the truck will run until it gets a half tank of fuel . the truck will start back up but want go far before shutting down again. put fuel in truck will run ,until half tank again and runs good

had the same exact issues, my lift pump in the tank was restricted with debriss, changed pump, runs great.

have changed pump in tank and on the fuel filter housing

My 04 will only start on either or roll start. New crank sensor. I checked for fuel getting to the fuel filter and I can hear the pump. Does the grid heater have to heat up for the cummins to start?

Negative. Only in cold climates will it make it noticeable easier to start with the grid heater, but it will typically not prevent it from starting unless its VERY cold, which is not typical for this time of year, of course. Further, I’m not following, are you saying that it only starts on a roll start, as in bump starting like you’ve got a manual transmission, get the truck rolling and pop the clutch?

Great article a lot helpful information. Found that the truck I was working on had four loose injector nuts. Tighten them all and the truck starts and runs great.

Thanks for the help I will definitely be going to diesel power products for any future parts or advice. Thanks

My 04 has an intermittent stalling problem. I can drive it for a few hours and it’ll run great then will sometimes stall. Engine will crank but won’t start. If i let it sit a few minutes it will start but then die. This will happen 3 – 4 times then will stay running and could be fine for hours. I replaced the lift pump thinking it was the culprit. I do not hear the lift pump run when the no start condition occurs. My question is what controls the lift pump and supplies power?

It definitely sounds as though its a fuel pump related issue. Your ECM controls the lift pump operation depending on key position, which goes through a fuel pump relay. Presuming the lift pump is good, since you just replaced it (again, making a presumption) look through all of your wiring and fuel pump relay to ensure there is no break or corrosion. Beyond that, I would recommend checking the power to the pump when you have these issues. If there is power going to the pump when it will not start, its of course a bad pump again. If there is not power, you’ll need to work your way back to see where its losing power. In some cases, it can be a faulty ECM not triggering / turning on the power to the pump. Further, as a side note, 2004 models originally had the lift pump located in the engine bay. Later, it was determined this was a bad location, causing them to be susceptible to failure. Dodge released a retrofit kit that would move the pump into the fuel tank’s pickup basket assembly. Not sure where yours is located.

Where is the fuel pump relay located on an 04 5.9? I only see a fuel heater relay in the distribution box.

You are correct, I misspoke. After some research again, I was thinking of when the in-tank conversion is done, then a relay is added. From what I can recall and after confirming with some quick research, there is no relay for the stock filter mounted lift pump. When the in-tank conversion is done, an in-line relay is added, but in your case, its completely controlled by the ECM. In the instances when your truck will not start, confirm if you can hear the lift pump cycling by turning the key to the on position and listening in the engine bay. If nothing, then its confirmed you’re either not getting power to the pump or the pump is bad. The stock pumps are known to work intermittently when they are failing, so unfortunately it may be that its going out again. I would recommend giving us a call and we can help steer you in a direction to get the truck back up and running reliably again. 888-99-DIESEL.

I will definitely call. Now I can get it to act up. I can drive it for about 2-3 miles then shut it off. Let it sit for about 5-10 minutes then it will continuously start and die. If it sits for about 15 minutes i can usually get it to start and drive. I’ll call soon. Thanks for the help!!!

That does sound like the lift pump is overheating and not allowing it to start if you try and start it when the pump is still “hot.” I had to read your symptoms several times, as it almost sounded like a different issue. In instances when it will start back up again immediately, but not as likely the longer it sits, that, in many cases, is actually the pressure relief valve on the fuel rail that is failing. But again, you are the opposite situation. We look forward to hearing from you.

My lift pump is located on the side of the filter housing. Thanks for the input and I will post my findings! I wish it would quit for good so I could track it down.

So does the fuel pump retrofit eliminate the hoising mounted lift pump?

Yes, the dealer retrofit kit will eliminate the filter housing mounted lift pump with a new unit that mounts into the fuel tank’s “basket” assembly. This will include a new wiring harness, as well. While this is a good upgrade over the stock filter canister mounted unit, I would recommend upgrading to a FASS or AirDog unit for better reliability and filtration over the stock units. Otherwise, you could always go with FASS’ DRP that is merely a substantially better lift pump than stock, but keeps it in the engine bay. This is better than the retrofit kit, but not as good as a traditional FASS that mounts to the frame rail. Overall, its a good way to get a much better pump with an easier installation and less expensive than a frame mounted unit.

Tighten the jam nuts at the end of the injector lines may have solved my issue. I have a very short crank time now(comparatively) after completing this. Thank you!

Hi. Found your write up to be very helpful but am still needing expert advice.

Here goes. Filled up the truck with diesel 5.9, drove 20 miles and truck died conveniently in front of son in laws work. Got out of truck to notice fuel spilling all over the road. Son popped hood and said it looks like it’s coming from fuel rail. Replaced the lines but now it won’t start. Cranks but won’t turn over. Lift pump works, got fuel in filter but only about 1500 ps. Neighbor put it on a computer and said it’s either cp3 or fuel injectors. Now before I start spending big dollars on injectors and or pump is there a way to test the pressure relief valve short of ordering a replacement?

Tia

Hi there, thank you for reaching out. With the truck not running, remove the fuel line on the top of the pressure relief valve and physically move it out of the way. That line routes relieved fuel from the valve back to the fuel filter canister. Fuel will take the path of least resistance and without physically moving the line off of the top of the valve, fuel coming out of the line will make it look as if it is coming out of the valve. Once the line is removed, crank the truck. There should be no fuel coming out of the top of the valve during cranking. If there is fuel coming out of the valve, it is bad and needs to be replaced. I would do the injector return test that is outlined in the 3rd to the last paragraph in that write up. If you have any other questions, feel free to give us a call at 888-99-DIESEL, as well.

Awesome, thanks for getting back

So, checked pressure valve. No problem there. Did the injector test and had lots of fuel with in a second. So that tells me it’s an injector. My question now is, suppose it’s only one injector gone bad can I get away with purchasing just one or do you recommend the whole set?

We get this question a lot. Yes, if you only have one injector that is returning higher than normal, you can definitely replace only that one injector. BUT, in our experience, when doing this, its typically not long before other / all other injectors begin to fail, meaning you’re in there again replacing more injectors. Obviously, its best to replace all of the injectors at once, and if the truck has in excess of 150,000 miles with the original injectors, the rest are probably on their way out, as well.

2005, stock, 5.9, 100,085 miles, auto. 90 degrees, humid and sunny. After a 70 mile interstate trip and 4 hours shutdown, with less than 1/2 tank of fuel remaining (fuel at least a month + old) at the first stop sign 1 mile away on the return trip, truck hesitated upon applying throttle to proceed but moved on without issue. Ran fine to next stop sign 2-3 miles away. Next 5 stop signs, 2 miles apart, engine stopped in mid-intersection of each upon throttle application. 15 seconds of cranking each time, restarted, idled smoothly, and ran to next intersection where it died again. On to highway speed at 55 mph, 3 miles and truck died completely. Coasted into parking lot, and gave up trying to proceed further for night. Returned with a used FCA temporarily removed from a twin good running truck of same vintage as above. Started after long cranking, stalled a couple of times but began running smoothly. Tried to proceed, but 8 miles up the highway, truck died again while at speed as if out of fuel. Towed to a diesel shop, and waiting diagnosis next week. Ideas from here for now?

EDIT by Dougie: Truck threw a P 0088 code. High fuel rail pressure.

Thanks for reaching out to us and sorry to hear about the issues with your truck. In regards to the P0088 code you’re getting for higher than desired rail pressure, you were correct in replacing the FCA as that is many times the cause, however, since it did not alleviate your issue, the next step would be to check the rail pressure sensor. Otherwise, we’ve seen that code thrown when its not necessarily the excessive rail pressure causing the issue, just the fact that the truck had higher than desired rail pressure during the “issue” because your RPM’s were lower because of the misfire resulting from the rough running condition, as an example. So again, its not that the high rail pressure caused the problem, its that the rail pressure was higher while the engine was running rough and even dying, than under normal circumstances. Its almost sounding like a fuel quality issue or even lift pump related. I’m sure the shop’s first order of business will be to check your fuel filter which will tell the tale of fuel quality after initial inspection. From there, presuming they will check the health of the lift pump and move on from there. Good luck in getting the truck back up and running.

I have performed all these test but truck would not start without starting fluid. It would not start without the fca unplugged but once it started I unplugged it and idle did get rough. Is that normal? I have replaced both pumps. Once running it has all power it needs and get a speeding ticket if not careful. Any help would be nice.

Yes, it is definitely normal for the truck to run rough once you unplug the FCA as the rail pressure will run higher than desired at the lower RPM’s at idle. If you haven’t already, another thing to check would be the rail pressure sensor as its sounding like possibly the ECM is not properly registering the amount of rail pressure until the truck is running. The simplest method would be to swap the sensor from another truck if possible.

Ok thanks. I did notice today when I tried to start after sitting for 24 hours the rpms only got to 100 and once ether kicked in it fired when it reached 200. It seems I may have 2-3 issues that may be going on. I will post what I find out. It may take a few days but I will post an update. Thanks again.

Have 2006 5.9 that is very hard starting when warm,starts fine when cold . Have changed both pumps ,and filter . My question is which sensor should I start with ? It was checked for codes at the dealer and nothing came up ..Help please ..

Hi there, and thanks for the question. The first thing we would recommend checking is your pressure relief valve located on top of the fuel rail, which there is a tutorial on how to do in this blog post. If the PRV checks out fine, then the next step would be to test the fuel return rate of the injectors. Good luck, and let us know if you’ve got any other questions.

I have an 07 5.9 that developed a long crank problem. it started cranking for 2 times as long as normal a few weeks back. Since then it has gotten long up to 15 seconds and sometimes an initial of 15 followed by 10. It is assumed that it’s taking this time to build up rail pressure. Once it starts it runs like a champ and has no issues running, pulling for hours or hundreds of miles, unless i kill it. This issue doesn’t change if it’s cold or hot, warmed up for first start in 3 days. As soon as the key is turned off and you quickly try to re crank it or let it sit for days its the same. I have put a plug in the place of the rail pressure relief valve and just finished ordering a rail pressure sensor. What are your thoughts on this one? Thanks in advance.

This sounds exactly like injectors that are returning too much fuel. I would check the fuel injector return rates while the truck is cranking. This can be done by removing the return line at the rear of the head and plumbing it into a bucket that can collect the return flow. During cranking, there should be a very minimal amount of fuel coming out of the line, as in drops of fuel, and definitely should not be a steady stream. If it is a steady stream or anything other than drips, we have injectors returning too much fuel and it is just taking excessive cranking to overcome the return and build up enough rail pressure to start the truck. Presuming so, the trucks fuel mileage is probably down, as well. Hope this help alleviate your issue. If in fact you are experiencing excessive return, the fix would be to replace the injectors and injector connector tubes. We have numerous options available and if you have any other questions, please do not hesitate to give us a call at (888) 99-DIESEL, send an e-mail to [email protected], or reply to this message, as well.

I have a 2005 just installed new injectors, wouldn’t fire. Deleted the relief and fired right up. Went for a little rip and it ran ok had code MAF that was unplugged. Went over the truck and got it buttoned up, had it idling for about 15 min. Went around the block and down the street it died and won’t fire at all now.

Did you completely clear the MAF code? You can leave the battery cables completely unhooked for about half an hour if you don’t have a scan tool to accomplish this. If you’ve done this, its possible you have a bad injector harness. Short of completely replacing, you can test it by disconnecting each wire from each injector and ohm testing the harness. You should get 0.05 ohms or less. If you have a pinched wire, it could easily be causing a hard or no start issue. Another thing to try, unplug the Fuel Control Actuator (FCA) on the CP3 injection pump and try to fire the truck. The FCA is a metering device, so if it fires up, immediately turn off the truck as it will overpressurize the system. But if it does start, chances are you need a new FCA.

Yes I cleared the code with my smarty. I tried unplugging the FCA and no change. I redid my injectors and injector tubes just to be sure, tried again and I got inlet air temp p0073, cp3 pump p0251, cooling fan p0480. Still no start. Thanks for the help so far.

Okay, first off the fan clutch code p0480. That could be a blown fuse or a bad fan clutch itself. While not something that “notoriously” fails, they can and do fail. The P0251 code, that seems associated with unplugging the FCA (fuel control actuator) and should clear and we would expect that not to return once cleared. The air inlet temp code could be related, but that is not stopping the truck from starting. I would suggest at this point, starting somewhat from the beginning and verify lift pump pressure first. Something is being missed here, you have to be losing pressure somewhere. For it to die randomly, the truck is either not getting fuel to the injectors or its electrical like the injector wiring harness. If you’re able to test what the fuel return volume of the injectors are for 10 seconds of cranking and what is the actual lift pump pressure, that would help in diagnosing the issue. Also what is the resistance reading on each injector solenoid and harness.

Ok so the injectors test out between 0.4 and 0.7 ohms and the harness tests at 0.1 ohms with a fluke meter. I think the fan code comes from a broken pin in the connector. I did a quick fuel return test and it looked a bit more then it should so I redid the injector install and double checked the torque specs. I cleaned out and dielectric greased connectors. I have not tried to fire since I did this. I have a 150 fass with new filters and the cp3 has a bag of parts kit. I don’t have an actual pressure reading yet but I am working on that. I will do a better return test and get back to you.

Once again thank you very much.

So it sounds as though the harness is good. Let us know once you get a new return test done as the preliminary test sounds as though it may be causing excessive return. But even at that, it would have to be very excessive to cause a no start issue. Possibly, you had an issue with how the connector tubes were seating into the injectors, as this is a common issue, and hopefully your re-installation cures this issue, if it was the culprit. Long story short, most people install the injector completely, then screw the connector tube in, when in fact, you need to slightly tighten the injector, then the tube, then the injector a little more, etc. so the tube can properly seat into the dimple on the side of the injector. Otherwise, fuel will bypass the injector, or even partially block it. Good luck!

Ok so just did a return test and I’m only getting about 10 – 15ml of fuel. I hand tightened the injectors and backed them off and installed the tubes and torqued to 50 ft lbs I know that more then suggested but I want to make sure they are seated. Could my cp3 be acting up? This is my hot street project and everything but injectors sat on my bench for over a year.

The return sounds good and your reinstall with the injectors and tubes is spot on. Honestly, they can use more torque than the recommended to really seat them well. Yes, starting to lean towards CP3. Did you just install the bag of parts, or had it been on the truck for a while? Have you tried swapping out the FCA with the stock one? Also, when you change out the fittings on the CP3 with the BOP, did you absolutely make sure that the little tiny ball was reinstalled? Its easy to miss.

I did the bag of parts a couple years ago. Was one of my first mods. I actually did drop the check ball in the driveway and had to order a new one. I just swapped the stock FCA in and no change at all. I’m honestly at a loss. I just need to move the dang thing so the fiancé can park in the garage now that the snow is flying. I defiantly need to get a rail pressure gauge. Any real way to see if the cp3 is done?

I have a 2006 2500 and it wont even crank over it just clicks so i pulled the starter put a new one in and it still just clicks i used a test light cheched the wire comming from the ignition and thats good the clicking is comming from a relay by the drivers side battery where do i go from here?

From the information you’ve given, this honestly sounds like you simply don’t have enough battery voltage at cranking. Your ECM requires a minimum of nine volts to do absolutely anything. What we would recommend doing first is to check the battery as you’re attempting to crank over the engine, so have one person holding a voltmeter on the battery post watching the voltage drop and another turning the key. Even though you may be showing 11+ volts at static level, you could very easily be dropping below nine when trying to crank, which would cause the relay to merely click.

I have an 07 Dodge 2500 with the 6.7 cummins and as above I am unable to start it after getting water in the fuel. So far I’ve dropped the tank, cleaned it and installed a new pump and installed a new filter. It was still showing low fuel rail pressure and gave me the error that the rail pressure relief had gone off so changed that and still wouldn’t start so changed the injector pump and had the injectors cleaned. It still won’t start but will try with a shot of either can jou give me any suggestions as to what else it could be?

I would be looking at injector return flow. Just simply cleaning injectors will not fix them. Water contamination creates cavitation under the high pressure that the fuel system is under. It will do just as much damage as sediment would. I would test the injector return rate for sure. The maximum allowable return while cranking is 90 ml per minute. So not much that’s only just over 3 ounces.

Great write up and thanks for giving out the information. It seems everywhere else you look for some help, someone wants to make money for helping others. I’m about to start the tests. Before I do, the not start problem I’m having is when we drive our 2007 dodge ram and park it and try to re-start it again in about 2-5 minutes later. Just cranks. I’ve noticed if you wait longer it takes a bit longer to crank and finally fires. If you at least wait somewhere after about 15-25 minutes later it starts fine. So if you take it out for a long trip and get back in it to start right away not a chance. let it sit for a while and it starts. We already have a new pump in the tank from the summer. If it were the pressure relief valve? Wouldn’t the pressure sensor set an engine code and light up telling not enough rail pressure? If so I’m going to the next step. if not then start with the valve and next in order. Thanks.

The pressure relief valve is a great place to start since you have already addressed the lift pump. When it is in its no start condition I would remove the Banjo bolt on the top of the relief valve and push the line out of the way. See if it is relieving fuel when you are cranking the truck. If it is perking fuel when cranking, the relief valve is bad. Sometimes they will throw a code and sometimes they won’t. I see this issue a lot with trucks that have high return rates on the injectors, so the injector return flow test would be the next test if the relief valve checks out good. Good luck and let us know if you have any other questions.

If I have to much return fuel from back of head should I try injector tubes first or am I wasting my time and just putting off the inevitable.

Unfortunately, its not common to have the connector tubes be the culprit for a high return rate unless you’ve had them out for any reason and they aren’t properly seated into the injector. In that particular case, unless they were just loose, you would have an issue where the tip of the tube has a seating ring around it from where it should be seating into the injector body, but not properly seating. But again, that only happens typically after you’ve had the injectors and tubes out. Further, its POSSIBLE for it to be the Fuel Control Actuator (FCA) of the CP3 injection pump, but in most cases, these don’t supply enough pressure, but your symptom would be caused by too much pressure. So yeah, you’re most likely needing new injectors. Let us know if you have any other questions.

With a longer start cranking and driving at 55 above no pedal repsonse (power nothing) and p0148, but drives, idles fine indicate or isolate problem better? If try describe better, engine taking extra time cranking to fire off, then when driving acceleration fine for few miles, when want power to go faster or load on engine past 55 there no power response, push pedal floor with nothing. Left off can continue driving no problems. Like dang governor on engine. Would these sequence of failed items be similar? Much thanks any insight/help.

These symptoms and the code you’re getting could be a handful of things because essentially that code is saying that the commanded (or desired) fuel pressure it not meeting the actual. Our recommendation would be to start at the beginning of the fuel system and work your way forwards. The big tickets items to check would be number one, lift pump pressure, both at idle, as well as at cruise. Next, check the pressure relief valve as it could be bleeding off prematurely. Third, have the return rate of the injectors tested. These three would be the most likely culprits, but it could also be the fuel control actuator (FCA) on the CP3 injection pump, fuel rail pressure sensor, or even an issue with the injection pump itself. Good luck and let us know if you have any other questions or what you come up with.

Hello,

2006 ram 3500 5.9 cummins, truck was working fine, set up for two weeks, drove on third week for about seventy miles round trip. probably ten miles from house sitting in traffic check engine light comes on. truck never ran rough or anything. probably had about a 1/4 tank of diesel. pull code and it is P0148. I changed pressure relief valve first. truck just cranks and no start. a week later changed the fuel control actuator, and same thing truck cranks but wont start. If it helps on cool mornings when i start truck it will rough idle and blue smoke for about 30 seconds then clear up.

Thanks in Advance

Thank you for the inquiry. We’re sure you are aware at this point, but just in case, P0148 specifically means High Pressure Common Rail Checksum. In other words, it means that the desired pressure as commanded by the ECM is not the actual pressure, which of course, could be a multitude of things. You’re on the right path by having replaced the pressure relief valve and the fuel control actuator. Because of the blue smoke, that leads us to believe its an issue with one or more injectors causing a high return rate, essentially creating a pool of fuel on top of the cylinder(s). However, it would still be a good idea to start with the simplest of things and check the fuel pressure (low side) as described in the original post. If that returns normal, we would suggest having a fuel return rate test performed to confirm the integrity of the injectors.

03 5.9 driving at 50mph truck acts as if it jumps out of gear I pull over turn it off checked it out saw nothing came lose tried starting it and it took forever to start for a sec with pedal to floor ran for couplease sec died now want crank and hole truck shakes when trying to crank turns over really fast pulled codes p0700 p0336 p1652 p1687 p0205 any ideas where to start contact me at 2258108018 I can explain better thanks

Unfortunately, this sounds like a lot more than a fuel related issue. Based upon your description and the codes, it sounds like a broken crankshaft.

2005, will not start, but if you let it sit it will. Had it in a garage for fan bearing, mechanic cut wires in front of fan

While we would recommend reconnecting the wires at the fan, it should not be preventing the truck to start, worst case is you’d typically get a P0483 or P0480 code from the wires being cut. Depending on how the truck had been running before the no start symptoms started up, its sounding like injector failure. In many instances, the longer the truck sits, it will become easier to start due to a high return rate of the injectors. With a cold cylinder, the air is more dense and will light off a little easier than a hot engine. We would recommend an injector return rate test first and foremost.

my husband has a 03 5.9 cummins automatic

the truck will start with and with out the fca plugged in at MAX fuel pressure

I have new cp3

injectors

connector tube

cam shaft position sensor

fca rail sensor

it throws 4 codes

1. cam shaft position sensor range performance

2. cam shaft position sensor A circuit

3. sensor reference b voltage low .

4. fuel rail pressure circuit high.

my husband has a 03 5.9 cummins automatic

the truck will start with and with out the fca plugged in at MAX fuel pressure

I have new cp3

injectors

connector tube

cam shaft position sensor

fca rail sensor

it throws 4 codes

1. cam shaft position sensor range performance

2. cam shaft position sensor A circuit

3. sensor reference b voltage low .

4. fuel rail pressure circuit high.

thanks in advance !!

Thank you for the inquiry and sorry to hear about the issues with your husband’s truck. Curious, did it have these codes before pump, injectors, etc. were replaced, or is this merely what its throwing now? What was the reasoning for changing the parts in the first place as you say it “will start with and without the FCA…..” or would it not start in the first place? As far as the rail pressure circuit high code, that’s caused from starting the truck with the FCA unplugged. If the cam shaft related codes were present before swapping out the cam sensor, its very possible you need a crankshaft position sensor, as these two work off of one another. Basically, you could throw a cam code, when its actually the crankshaft position sensor. Overall, if you can give us a little more information or you’re welcome to give us a call and we can see if we’re able to help diagnose a little further with you.

2003 dodge 2500 Cummins. Won’t start. Replaced fuel filter. Can’t get fuel into filter canister. Replaced fuel lift pump in tank (factory upgrade previously done). Still can’t get fuel into filter canister. Seems like pump comes on but won’t prime and truck still won’t start. Ideas greatly appreciated!

Would the truck not start only after replacing the fuel filter? If this is the case, then you typically only need to bleed the air out of the system. However, if it wouldn’t start before the fuel filter, then the health of the previously installed lift pump would be the first place to check, as we’ve seen these also fail numerous times. They don’t fail as much as the block mounted pumps, but still definitely fail. You should be able to bump the key and listen for the hum of the pump at the fuel tank. If you can’t hear anything when bumping the key, then its likely the pump is bad or just the power supply to the pump (like a bad fuse). Also, if your pump is running, then check for any air leaks before the filter. Let us know where you’re at and good luck.

my engine revved hi for a couple of seconds b4 i shut it off and now wont start. had everything checked and they said there is no power going to the injectors. does that mean my pcm/ecm is bad?

While its definitely possible your ECM is bad, its not very common. Does the truck crank over, just not start? How many miles are on the truck? One scenario that is more common and is inline with your symptoms is a failed Fuel Control Actuator (FCA) on your CP3 injection pump. When the FCA fails, or loses power from the ECM, it loses its metering capability, meaning the CP3 now runs at full bore, thus your RPM’s quickly increase to high levels. Then, what can happen is because of the excessive pressure, it actually blows out the Pressure Relief Valve (PRV) on the rail. When the PRV fails, your fuel rail cannot maintain adequate pressure, thus the truck won’t start, but will still crank over. You can also give us a call and we can discuss more about the symptoms and other possible fixes. Good luck getting the truck running again.

Hi!! Thanks for all the advise you have given to everyone now I guess it’s my turn to try and stump you…. I have a 2006 ram 3500. My initial issue was a rough idle, replaced the fca and did a general service oil filters etc. No change. During winter started having trouble starting and while out of town ended up replacing 1 battery ( I know I know need to do both) but at the time I could just do 1…. anyways truck still had a rough idle and then would not start. Tested injectors they were bad and replaced all 6. Everything went fine during replace all torqued to specs etc. Went to start afterwards and for some reason it shorted out my grid heater literally melted the metal connector between the 2 bolts then fired right up. Idle sounded great everything sounded perfect ran great everything… now to my current issue. The next day after it sat all night wouldn’t fire at all just cranked and still having this issue. If the truck is cold ( hasn’t ran for 6 plus hours) it has to have either to start I’m fully aware of either being bad…. once it’s started with either I can drive to work shut it off and 4 hours later it will start right up. So the start issue is only when the motor hasn’t ran for 6 plus hours if the motor is warm I have no issues. I have just left my grid heater how it is it’s been 60 plus degrees right now and mid 30s at night. I have gone back through and re torqued all the tubes from the injector install just in case it was bleeding fuel back and no change. Today had my other battery tested and they said it’s bad ( won’t even register on the meter at napa) so long story short my question is would my grid heater shorting out cause my issue or would 1 bad battery cause this issue or something else you can think of? I’m definitely planning on replacing my other battery soon I know that has to be done just not sure if I’m looking at another issue. Thanks for your time you guys are great!!

While a bad battery can definitely limit the truck’s ability to start, it doesn’t really sounds like that’s the root issue. As long as the truck is turning over relatively easily, then that’s not it. It sounds more like a pressure relief valve issue based upon your description. Sure, if you’ve recently driven the truck and the alternator has been able to charge the batteries, being able to crank it immediately following will be easier. In order to prove this theory, you could let the truck sit for the 6+ hours as you’ve described, but then have another vehicle running next to yours and connect the batteries with a pair of jumper cables (go to your known bad battery) and see if the hard start issue is still there. Presuming it is, your next thing to do would be to take the return line off of your pressure relief valve and see if there’s fuel sitting in top of the relief. If there is, its possible that’s the issue. Next, try and crank the truck with someone watching the top of the relief valve (note, do not stare right at it as fuel may spit out). No fuel should come out of this relief valve when cranking. If fuel comes out, you should either get a new pressure relief valve, or replace it with a pressure relief valve block off. Anyways, that’s where we’d go next in diagnosing this based upon your description….GOOD LUCK!

I replaced the PRV with a block off and still no start… any other suggestions??

Thank you for the feedback, and sorry to hear the PRV Block Off didn’t solve the issue. Presuming the truck is turning over relatively well with the one suspect battery, the next place would be to check is the fuel pressure off of the lift pump. In order to gauge this, you’ll probably need to hit it with ether again to see where its at. One important thing as mentioned in the original post, is to watch it not only as soon as the truck is started, but while its running and during start up. Many times, the stock lift pump will show adequate pressure as soon as you get the truck fired, but then fall off completely after 30 or so seconds. When this happens, you can get drain back of the fuel, giving another reason as to why the truck won’t start the longer it sits. I wouldn’t say these fuel systems are necessarily finicky, but there can sometimes be several reasons for a similar symptom.

I have a 03 dodge cummins with no start cold or hot .I can take the fuel filter out and wipe the bole clean then more than likely I have to start it with wd 40 but then it starts fine for several times after that 2 to 3 sec. every morning I even let it sit for a week and it started right up .Then I run it to town 10 mi. .Then slowly slowly, longer starts till [ no start] until I mess with the filter again .ps new filter .cleen fuel. new in tank pump.

This seems like somewhat of an odd situation, but lets see if we can figure it out. It doesn’t sound like its necessarily the action of wiping out the fuel filter base that’s allowing it to start, but rather the WD-40. Overall, it feels like a pressure relief valve or injector issue. In one situation, if the truck is sitting for longer periods of time, the fuel is essentially draining back from the rail, and creating an air pocket in the rail. Once you hit it with WD-40, its enough flammable gas in the chamber, it fires the truck off of WD-40, bringing fuel into the rail since the CP3 is moving now. Then, the longer it sits, it drains back again. The next theory would be high return rate on the injectors. Basically, the same theory, but instead its draining fuel into the piston bowl. But with this one, usually the truck will pour white smoke when you’re trying to start it as the bowl has a considerable amount of fuel in there. To test the PRV, remove the return line on top of the PRV and crank the truck with someone watching the valve (don’t stare at it as fuel may squirt out). At crank or idle, no fuel should be coming out. If there is, you need to either replace with another pressure relief valve or with a PRV block off. In order to get to this point, you may need to use something like ether again to fire the truck to even see the fuel coming out.

Darrell needs HELP

2003 Cummins 5.9, 167,000 miles. Long start when cold (less than 50 degF), and no start (unless you use starting fluid) when it’s really cold (less than 25 degF). If you keep it plugged in, it always starts, though still can require a long crank. I’ve performed every single test you suggested, and everything is in spec, I also installed a PRV block-off. I ran the return flow test several times and it’s returning 160mL in one minute. I will say though that I’ve only been running it at idle (so a little less than 1000 RPM). Should I re-run at 1200 RPM? Also, I’ve seen other sites that say to remove the FCA harness when running this test. I tried that once and had 350mL of return in 30 seconds. I also purchased a blocking tool to block each fuel rail feed tube connection one at a time to see if there’s a leaky injector. I’ve only been able to check 3 so far (2 are tough to get to, and one fitting is seized up). Two of the injectors accounted for 22mL each, and the 3rd account for 37mL.

Based upon the numbers you’re giving us, you’re at the absolute maximum acceptable range of return flow and that’s at below the recommended RPM range. If you were to bring it up to 1200 RPM, you’ll be getting over that 160 mL threshold, meaning that most likely your injectors are the culprit for the hard/no start.

Hi, I have a 3500 5.9 2003 Ram p/u.

The other day it seemed like it was running out of fuel (full tank) it stalled and after several minutes of cranking it started and I was able to get home.

I have no power at relay (other than hot from battery) and FUEL GAUGE is dead…..?

In tank pump. Working . Sounds electrical

Hi there and thanks for the inquiry. Yes, it definitely sounds electrical. The fact that the fuel gauge is not working should not be the culprit for the hard / no start. However, it could be an indicator of what is causing the issue. Because there is a joint wiring harness from the fuel tank’s basket which stores both the fuel level sending unit and fuel pump wiring, that would be the first place to inspect for any corrosion or breakage of the hot lead and/or ground. It will probably require a visual inspection of the entire harness and you could also run a continuity check of each wire.

So, hot wired fuel pump, works,

checked relay, working.

Ran jumper ground to pump, works but still no gauge. Sounds like a ground problem, ( I get a slight movement on fuel needle JUST a tiny bit).

There’s a bundle of ground wires bolted to front fender, dose this bundle run to rear of truck among other places?

Not sure what to think about gauge as it is a separate circuit I believe, but must end up going to ground somewhere.

I,ve checked grounds and plugs/connections. Cleaned battery posts.

Today, no left headlight and no parking lights. …update, headlight came on then went off again. Maybe ready to burn out, hum

Was thinking of a local ground to frame at the rear. Can black wires with a color tracer be grounded to frame.?

Long winded I know but may help. Thanks for your response and cheers

Glen

This definitely sounds like a grounding issue. There’s several physical grounds on the truck, and one that goes forgotten sometimes is under the bed on the under side of one of the box supports. I’ve personally seen a truck go completely haywire when this strap was not hooked up, also check the ground strap to the front inner fender from the battery. These need to be clean, even take the one at the fender and scratch up the surface of the paint. Please also make sure your battery terminals are free of corrosion. To answer your question about the bundle of wires, if its the one I’m thinking about, yes, it goes to the rear of the truck, ending at the taillights and trailer wiring. So again, start tracking down all physical grounds and cleaning them up, making sure the wires aren’t broken anywhere. Good luck.

Okay, so I have a 2012 6.7 Cummins. Put an Arson 3 kit on cp3. Truck wouldn’t start. Put stock actuator valve back on and started right up. Decided a week later to put a plug in my rail because truck just seemed to want more fuel. It would go into limp mode at higher speed. It would just over rev. And I would lose power. Anyway, couldn’t get the relief valve out to save my life no matter what I tried. Ended up having to take the whole rail out and use a vise. Re installed averything along with a big line kit from glacier. Now I’m getting fuel through the added mk2 filter and nothing out of the supply line to the rail. Truck won’t start. Just cranks.

Also, when I was fighting the reief valve I was using a cheater and slipped grounded my wr much and cheater and hitting the positive post in my battery…. (what more could go wrong right?). So onvioulsy big arc on that one… not sure if I shorted something or what the hell is goin on.

Anyway. I’m out of ideas. Any help would be awesome.

Sounds like you’ve got your hands full! Regarding the initial issue, we have seen failed FCA’s right out of the box with several manufacturers of aftermarket kits such as this. We’d recommend getting with the manufacturer and getting a new FCA based upon the information you’ve provided. As far as the slipped wrench, that most likely didn’t cause the issue, it happens to the best of us and rarely causes a real issue. You don’t mention that you’ve bled the system to remove any air, and it sounds like what the cause of your most recent issues at least. If you haven’t already, remove the return line for the injectors at the back of the head and bump the key to engage the lift pump to push fuel without air blocking it. Let us know if you’ve already done this and we can take it from there. Good luck!

I have an ‘06 5.9 that won’t start. Iniatially it would die when slowing down to stop or turn. After draining the fuel filter it would eventually start and run fine at highway speeds. Then after 10-15 mins die again when slowing down. Eventually it would not start at all. I’ve replaced the fuel filter and it still won’t start. The fuel filter refills when I let the pump run to prime it. It has fuel in it every time I drain it. Your help would be greatly appreciated

Thanks for the question, lets see if we can help figure out your issue. Based upon what you’re saying, the entire system is having difficulty maintaining pressure since its dying after you’re essentially reducing the throttle input / desired amount of fuel volume. The first thing to check if you can is actual lift pump pressure. What we’ve seen time and again, is that even though its pumping fuel, its not enough, and it will “give out” just driving down the road. Then, you give it some time crank and repressurize the system, and it will keep up for a little longer. Because of the high failure rate of the lift pumps on these trucks, that would be the first guess. Secondly, you could have a pressure relief valve that’s allowing excessive fuel return. This one isn’t quite as likely, though because of how its dying as you’re slowing down. Typically, this valve will return more fuel as more throttle is input, but yours sounds like the reverse. However, this can be a finicky system, so it would be a good thing to check, and its easy enough to do so. Just remove the return line off the top of it and crank the truck. See if any fuel is spitting out of it while cranking, if there is, it needs to be replaced or blocked off. These would be the first two things to check over that are the biggest culprits. Let us know what you find and we can take it from there.

As far as I can tell it seems to be the lift pump. I’m getting fuel to the filter, but when I take the cap off the fuel tank and bump the starter I can’t hear the lift pump running. I guess the injection pump is drawing fuel to the filter.

Yes, if you’re able to get the top off of the fuel tank and you’re not able to hear any “hum” from the lift pump, most likely its dead. Your best bet would be to replace with a FASS or AirDog system so you don’t have to worry about the issue again. And yes, the CP3 injection pump does have the ability to suck fuel, just not very efficiently, so that’s probably how you’re getting fuel to the filter. Let us know if you’ve got any other questions and you’re also welcome to call in and discuss.

Update. Replaced the lift pump and the truck runs great again. Thanks for your help.

Excellent news! Great to hear the truck is up and running again.

Have an 07 5.9 today it just wouldnt start after shutting off for 2 minutes and the rest of the day on a trip if shut off has also had longer cranking lately during start up, cranked like crazy but no start, lost prime. Can hear lift pump coming on and if crack drain valve i get a good stream coming out with pump on. No visible fuel leaks, injectors are farely new, we got it running instantly with small shot of starting fluid (had no choice 300 miles from home im Michigan’s U.P.) ran fine driving and idling never skipped a beat.

This is showing all of the signs of a failing or failed pressure relief valve. You can either replace the valve with a direct replacement, or some will take the route of installing a pressure relief valve block off. This part has a high failure rate, so is most likely causing the issue. The factory valve has a light weight spring that relieves pressure at a predetermined level, but as that spring fatigues, it will bleed off prematurely, causing it to lose prime. Especially since you have newer injectors, its highly likely this is the cause. The blog post explains how to test this and confirm so you can be more guaranteed. For reference, below are links to both the replacement relief valve, as well as a block off. Please let us know if you have any other questions and we’d be glad to help.

https://www.dieselpowerproducts.com/p-15051-bosch-f00r000632-pressure-relief-valve-03-07-59l-ram-cummins.aspx

https://www.dieselpowerproducts.com/p-7759-industrial-injection-pressure-relief-valve-block-off-03-07-cummins.aspx

2010 Ford F-350 with 2003 5.9L 24v Cummins swap. Fass Titanium Fuel Pump w/ New Filter & Seperator

My Fummins cranks, but will only start with ether. Once started, it idles and runs fine, but will not restart unless I spray it again. I’ve cracked open the PRV, cranked several times and no diesel leaks from the top banjo bolt. I’ve capped each injector separately with the miller injector block tool and cranked, but still no luck. The FCA was unplugged and no luck. I’m getting good pressure from the FASS to the CP3 pump, but yesterday I noticed if I remove the CP3 output line that goes to the fuel filter block off plate and crank the engine, the fuel just drips out. Fuel system has been primed and there’s no air. Is the CP3 known for getting clogged? If in fact it is clogged, how does it start and run with the use of ether? I feel the clogged pump would starve the rail/injectors and cause the truck to run like crap.

Any input would be greatly appreciated.

First of all, sounds like a very cool conversion. Most opt for the simpler 12 valve conversion, always good to see a common rail conversion. In regards to your issue, it sounds like you may have too much injector return flow on 3 or more injectors. Blocking off single injectors will isolate the issue if only one or maybe 2 injectors were returning to much. If all of them are returning excessively, it typically won’t matter if you block one off at a time, and you’ll need to measure the return flow for all 6 injectors.

1.) Maximum allowable leakage for all injectors combined is 160 ml per minute: check when coolant temperature is above 180 degrees, 1200 rpm and fuel rail pressure is equal to 20,305 PSI.

2.) If you have a no start condition, maximum allowable return is 90 ml per minute at 200 rpm cranking speed, be careful not to over heat the starter during testing.

Good luck, and please let us know if you have any other questions.

Hey yall,

Got an 06 5.9. Had a bad lift pump, replaced it and immediately started having a long crank issue. Truck always starts but turns over longer than it should and runs rough for 3-5 seconds with a puff of whitish smoke. Only when sitting for several hours though. No issue when warm, fires right up. Also, I have noticed a lack of power. No codes, truck is mostly stock with the exception of an Edge, 250k miles, only ever replaced one injector and had the issue before that.

First things first, we’d recommend pulling out the Edge and returning to stock, just to make sure there isn’t some type of failure in the circuit board there not allowing the rail pressure or MAP sensor (and injector harness if its a Juice with Attitude and not an EZ) to read properly. Once that’s returned to stock and if its still doing the same thing you’re going to need to run an injector return rate test. At 250k miles, its likely you need to replace the rest of the injectors. The original injectors in the 2004.5-2007, sometimes called the “505” injectors had an exceptionally high failure rate, enough so that Bosch, the original manufacturer, revised them.

Hey yall,

I have an 06 5.9 that had a bad lift pump, replaced that and immediately started having a long crank issue. Truck always starts but turns over longer than it should and runs rough for 3-5 seconds with a puff of whitish smoke. Only when sitting for several hours though. No issue when warm. Truck has 250k miles with only ever replacing one injector and had the issue before that. All stock except for Edge and exhaust. I’ve noticed a lack of power too. Not much but enough for me to feel.

Thank you for the inquiry. Your symptoms definitely sound injector related, especially with the model year of the truck and having 250k miles. What’s interesting is that it only started after replacing the lift pump. Depending on how long this has been going on, its possible you introduced some air into the system which ended up putting the final nail in the coffin for your other injectors. The real way to confirm this is to have a return rate test performed on the injectors, but again, they are delivering all of the typical symptoms. That is the first place we’d recommend checking and go from there. If you need any recommendations on quality injectors or any other questions, feel free to reach out to us.

Have 2006 dodge 3500 5.9 The coil light is staying on constantly ,the grid heater is not working. I have change out soliniod /rely with a new one with same result. bench tested grid heater to power supply and it glows red quickly and appears to be working fine. Also there is a constant clicking sound ( like a relay ) at a fairly fast rate coming from drivers side back or lower back of the motor when key is in the on position (not running )have never noticed this before and is hard to locate exactly where it’s coming from. Having hard starting issues and stalling at low rpm. If you get out on the highway it seems to perform okay. Coil light will still be unlimited ,not sure if this causing some kind of limp mode ?

Any advice would be great . Thanks for all formentioned information on fuel system troubleshooting , it has been really helpful .

HI there, thanks for checking in with us and the accolades. In terms of the coil light staying on, the first thing to check or replace would be the IAT (Incoming Air Temperature) sensor. If I remember correctly, the IAT must sense 55+ degrees Fahrenheit to trigger the grid heater. If its malfunctioning, then it could be causing the light. Also, check the continuity on the grid heater wire as we’ve seen those get corroded out for various reasons. In regards to the clicking, if you’re not able to follow the clicking sound, you could start pulling fuses one at a time to see what essentially causes the clicking to stop and then locate it that way. Hope this helps, if you have any other questions, please feel free to contact us or reply to this post.

Thanks very much I’ll try your suggestions .and get back to you

with the results.

Hi, I have a 2003 with a 5.9 Cummins. It starts and idles fine but after about 5-7 mins. it kills just as if you turned the key off. The truck will crank right back up and do the same thing repeatedly. If I do try to drive the truck while it’s running it bucks and barely wants to run. I have dropped the tank to make sure that the pick up screen is not clogged, there is no lift pump in the tank, I have changed the filter housing mounted lift pump, a new ful filter and FCA. No check engine light on but did hooked a scanner up to the truck and got codes P0462/P0463 fuel sensor voltage high/low, which I think is why the fuel gauge doesn’t work but truck does have fuel in the tank, and P0700 transmission solenoid not sure what that means. Maybe because of the bucking when I try and drive but don’t know if that would cause the killing issue when idling. Been trying to figure this out for a good while now any help on what to look for or check would be greatly helpful and appreciated.

The P0700 is a general code that is just telling you that there is an issue with the transmission. Unfortunately, you could have a few things going on here. I would be looking at the high pressure side of the fuel first and foremost. Checking the PRV and also doing the injector return flow test as described in the original post would be the first items to check. You could also have the torque converter stuck in lock up or something causing the bucking and killing of the engine, but being its so random and its fine when you first drive the truck, its more likely on the fueling side. Good luck and let us know what you find, please.

Still troll shooting the 06′ but have different issue with my 07.5′ 6.7 3500 . Have no power to the lft pump ,tried to scan DTS codes with my smarty ,but comes up (wrong com error) this smarty has been vin coded to this truck for years. I’m hoping my ECU didn’t give up th ghost . All fuses good checked all wiring for breaks and could not find any visible .died on flat paved road.bench tested lift pump and it work fine and tried a new one in the truck to no avail. Any suggestions to check or try would be greatly appreciated.

Love my cumminsis ,but not having good luck lately .thanks again, Shawn B

Definitely sounds like you’re having some bad luck lately! Since you’ve got a Smarty, the first thing we’d recommend is to just try and tune the truck with the Smarty to confirms its responsive and hopefully load a program to “wake it back up” so to speak. However, if the ECM is non-responsive, it will not let you load it in. Otherwise, if you have, or can get your hands on a scan tool, try to connect to the ECM. If you’re not able to, check over your power and ground for the ECM and all connections to both batteries to ensure nothing is corroded or shorting out. Good luck, let us know what happens, please.

06 5.9 link to a YouTube video .my truck is making this exact sound (ticking or clicking) ,but sounds more like it’s coming from the back of the engine rather than the grid heater .going unhook temp sensor from Tranny and look for code#712 also the TTVA where the shift cable attaches has a constant buzzing at the same time (key on not running).

Link :long cold / no start below.

http://youtu.be/PIPP_sPtofw

Will do with 07.5

Thanks again ,this is the best diesel blog on the web!!

Hi there, 06 3500 5.9 cummins update.cleared trouble codes and coil light stays off changed grid heater relay and is working .pulled top 30 amp fuse number 42 ( diesel PCM ) and the clicking noise from back of motor stopped but then sound like the lift pump surging on and off when pulled ,clicking sound returned as soon as the fuse was reinserted. Getting code #713 ,clear code and comes back soon as key is turned on.

Engine stalls at low RPM or shifting into reverse or drive .clean fuel ,new lift pump ,new filter and changed out AFC.

Okay, so it sounds like the grid heater is handled. The P0713 code is a trans temp sensor too high, which can be kicked when the wiring is shorted to ground, or the sensor itself is grounded. We’ve seen this wire get pinched when reinstalling the transmission pan after a service, and this code will cause a ton of issues. If you determine that the issue is constant, unplug the temperature sensor at the transmission. After you’ve done this, you should ordinarily return a code P0712 (low temperature error). If you receive that code back, then the issue is inside the transmission (either the wiring inside or the temperature sensor itself). If you still receive a P0713 after clearing with the connector unplugged, your short circuit is external to the transmission. The stalling you’re experiencing could very likely be caused from the transmission being stuck in lockup or other issues with the torque converter.

06 dodge 5.9 disconnected trans temp sensor .cleared DTC codes .put key to on position ,the horn and the flashers went of once .code #713 returned. may you be able to elaborate more about lockup or torque conveter issue.

Thanks, Shawn B

If the torque converter is in lockup, its kind of like when you start a rig in a high gear without using the clutch, or coming to a stop, again, without the clutch. The engine is getting all of its power through the transmission, making it buck and lurch when it should be slipping. The P0713 code, as mentioned, is excessive transmission temperature, which extended periods of high trans temp are the number one killer of transmissions, but your no start issue coupled with the sounds its making definitely does not sound anything transmission related. Right now, it sounds like there are a multitude of things going on, honestly, which is starting to make me wonder if there simply isn’t an issue with either the ECM or a general grounding issue. On one hand, you’ve got the trans issue, on the other, a fuel related issue, then the grid heater you mentioned. All of those are relatively unrelated, but electronic at the same time, so again, possibly the root cause of all of this is really in the computer. Diagnosing an ECM does require a professional grade scanner, but what you can do is visually check over the grounds, the alternator, and power to ensure there’s no corrosion, wire breaks, the usual. I apologize this one isn’t a straight answer, but again, seems there are several things going on here.

I have a 2004 Ram. No start. Fuel psi on scanner always reads 340 psi all the time. I followed your excellent instructions all the way up to the injector fuel return volume. I was getting over 300 ml fuel in 1 minute cranking. This is where I am stumped. I removed all the fuel injector lines and capped off the fuel rail. Even with all injectors lines disconnected, I am still getting 90 ml fuel return in 15 seconds. I know I have the correct line from the back of the head. Any idea where the fuel could be coming from? A small amount of fuel will trickle out of the return line even without cranking, when the lift pump is running.

Erik, thank you for the inquiry, lets see if we can get to the bottom of this. First of all, we need to get some clarity on one thing you mentioned. If you had removed all of your injector lines and capped off the fuel rail, you shouldn’t be getting any return as there would be no fuel going to the injectors whatsoever. So, when you say you’re getting 90ml of fuel return in 15 seconds, where are you measuring that fuel from? If you really are measuring return fuel with the injectors disconnected, you’ve got an awful lot of fuel sitting in your cylinders. In terms of capping off the injectors, that’s really only for determining an issue with a single injector in which you cap off one at a time and run the test six different times (one for each injector). Maximum leakage for a no start condition is 90ml per minute at 200RPM cranking speed, so if you are somehow getting 90ml in 15 seconds, you’ve got highly excessive return, possibly caused by the fuel control actuator overspeeding the CP3 literally just dumping fuel coupled with bad injectors that are letting it overflow. Otherwise, it could easily be that your injectors are completely shot.