Ford has in my opinion some of the best looking and sounding diesel pickups, with my personal favorite being the 2003 to 2007 Superduty with the 6.0 under the hood. On any given day, I can drive through town and spot dozens of classic Fords, but not just the 6.0. There are tons of 7.3 and 6.4 powered versions still working on jobsites and roaming the streets as well, and of course you can’t forget about the 2011+ 6.7 either. GM and Ram owners love to come up with acronyms to describe Ford trucks as unreliable or needing repairs daily, but the truth is, any older truck will need upkeep to stay on the road, but that doesn’t mean you need to spend a fortune every month on repair bills. Yes, the 6.0 Powerstroke is the red-headed stepchild that requires extra attention, but today we’re focusing on some simple and cost-effective upgrades you can make to your older Powerstroke to improve its function, performance, and reliability.

7.3 Powerstroke

To keep things simple, we’ll break it down by engine generation, and that means starting with the 7.3-liter Powerstroke, since hardly anyone drives an IDI anymore. The 7.3-liter Powerstroke was first found midway through 1994 and saw use until 2003, and boasts a massive 444 cubic inches of displacement, making it the largest modern diesel engine ever put into a pickup. Its power output was rather modest given its size, as its maximum rating was 275hp and 525lb.ft. of torque. The 7.3 is one of Fords most reliable powerplants as well, and it can routinely be driven to 500,000 miles or more with only basic maintenance needed. But as always, there is room for improvement.

Fuel Bowl Delete & Regulated Return

On top of the 7.3 sits a large fuel bowl assembly, and it contains a fuel filter, a pressure regulator, and it distributes fuel into each cylinder head, but the fuel bowl is also a very common source of fuel leaks. There are several O-rings that can shrink or crack as they get older, and the pressure regulator spring can become weak and give a drop in fuel pressure over time. While Ford does offer some updated parts that will fix the leaks and low pressure, there will still be a design flaw which causes fuel to deadhead in the back of each cylinder head. This causes unequal fuel distribution to the rearmost cylinders on the engine, which can cause rough and noisy operation. The fix for all these problems is a regulated return fuel system from Driven Diesel. This will eliminate the leaky fuel bowl and regulator assembly, but also contains fittings and lines to re-route fuel and allow it to flow through the cylinder head and exit from the rear rather than deadheading. Circulation means cooler fuel, more equal distribution to the rear cylinders, and even better throttle response and more horsepower. Because it does away with the stock fuel filter, you will need to upgrade your filtration as well, but a FASS lift pump and filter combo is the perfect companion upgrade to the regulated return system. This will remove any dirt, water, or air that’s trapped in the fuel, further improving fuel mileage and power at the same time.

Traction Bars

Any leaf sprung truck can exhibit symptoms of axle wrap and wheel hop, but the OBS era of Powerstroke (1994-1997) are particularly susceptible, and when wheel hop does occur, sometimes its followed by a broken u-joint, pinion yoke, or even a driveshaft failure. While letting off the throttle is a wise move to avoid breakage, what you really need is a way to harness all your torque and horsepower without breaking parts, and that’s where a set of traction bars come in handy. Longhorn Fab Shop traction bars are made from heavy duty 2” steel and create a solid link between the bottom of the axle and the frame which converts the axle’s twisting motion into a straight pushing force which prevents wheel hop and keeps the tires planted firmly on the ground. Because the traction bars use a heim joint at each end, the axle is still able to cycle up and down and articulate freely so your ride quality will remain intact. It’s also worth noting that traction bars are especially useful if your truck is lifted with a block between the axle and spring pack.

Boost Fooler

In an effort to increase performance of your 7.3 Powerstroke, many owners will install a larger turbocharger, modify the wastegate, or even install larger injectors, and these modifications together you send more air and fuel into the engine, which of course means more horsepower. One thing you may not be aware of, is the computer has a built-in boost limit, and once you exceed that limit with your new parts, the computer will defuel and pull back as much as 60 to 80 horsepower to try to keep boost under the predetermined limit. That directly counteracts your new modifications, so in order to prevent the defuel condition, you have a few options. If you are running a stock computer and you don’t want to mess around with tuning just yet, an inexpensive fix is a Boost Fooler from BD Diesel. This will allow the turbo to produce more pressure by limiting the signal being sent into the ECM to keep it under the limit, so the de-fuel doesn’t occur, and for less than $20, it’s an easy way to get the most out of your modifications.

6.0 Powerstroke

Call me crazy, but my favorite Powerstroke of all time is the six-liter. They were produced between 2003.5 and 2007 and feature a few technical upgrades over the 7.3 including four valves per cylinder and a variable geometry turbocharger. Yes, they have a bad rap, and yes, they can be expensive to maintain, but when you hear a tuned up 6.0 at wide open throttle, all the problems in the world seem to fade away. Stock, they make 325hp and 560-570lb.ft. of torque which isn’t a ton by today’s standards, but because they were built before DPF systems were implemented, you have a little more latitude when it comes to selecting your performance upgrades. Instead of common rail, the six-liter still used the same HEUI injection system as the 7.3 where high-pressure engine oil forces fuel into the engine via a plunger inside the injector. Because of this, the 6.0 can benefit from the same fuel bowl delete and regulated return fuel system as the 7.3 did, but there are ton of other budget upgrades you can do as well.

Cleaner Coolant

One of the more common failures on a 6.0 (the EGR Cooler) can be traced back to a failed engine oil cooler, but the root of the problem lies in the engine block. The oil cooler is a liquid-to-liquid heat exchanger, and because of the way the 6.0 blocks were cast at the foundry, a small amount of dirt is present in the coolant passages, and it slowly works its way out over time and winds up in your coolant. This dirt will eventually plug the small passageways in the oil cooler, and when that happens, coolant flow is blocked from reaching the EGR cooler, causing the failure. But, if you can prevent the dirt from plugging up the oil cooler, you will save both parts.

Sinister Diesel makes many products for the 6.0 Powerstroke, and their Coolant Filtration System is the perfect way to clean up your antifreeze and prevent damage of your existing parts, or if you just replaced the EGR and oil coolers, a coolant filter kit is the best way to protect your investment. It installs very easily by routing coolant from a heater line, and the filter is mounted up front in the engine bay making for easy replacement. The Sinister filter head has two valves mounted inline, allowing you to shut off coolant flow so you won’t lose any extra during a filter change, and once you’ve gone through the initial system clean out, (swap filters at 500 and then 3,000 miles) you only need to replace the filter once a year.

Airflow Restrictions

On a diesel engine, eliminating restrictions in airflow will always free up horsepower, add efficiency, and lower EGT, and the Powerstroke is no different. One overlooked area on a six liter is the intake elbow. The stock tube running from the intercooler to the intake elbow is made from 3” diameter tube, and the elbow itself has a sharp 90° bend right before it enters the intake manifold. The Banks High-Ram intake and tube combo has 64% less pressure loss than the stock elbow, and it achieves this by using a larger 3.5” diameter intercooler tube and a redesigned intake elbow to allow air to enter unobstructed. This is the perfect companion to a cold air intake, and a larger intercooler as well.

Exhaust Upgrades

With all diesels made after 2008, you’re pretty much stuck with the stock exhaust and its aftertreatment systems which take nearly ALL the volume away from your exhaust note. For many gearheads, this is a huge bummer, but the great thing about driving a pre-DPF 6.0 is the catalytic converter can stay in place without killing a ton of sound. There are many aftermarket exhausts you can install with the stock cat under the truck, so if you want bed stacks, dual exhaust, a single 4” system or even a muffler delete, it’s all fair game on a 6.0 or 7.3. For the best combination of sound and performance, a system with a 4” straight through muffler is hard to beat, and MBRP offers many different combinations that will meet nearly any budget and style. Their 4” turbo back system comes with a new down pipe, flanges to attach your catalytic converter, a muffler, and of course all the hangers you’ll need to easily install the system in an afternoon. When it’s on, you’ll enjoy the newfound sound, looks, and performance of your six-liter, and it won’t annoy your neighbors either.

6.4 Powerstroke

In 2008, Ford turned the world upside down with their first common rail diesel. Sure, it took them five years longer than Ram to finally use common rail injection, but when they finally showed up, they kicked the proverbial door down. Performance enthusiasts loved the new hot-rod powerplant since it was the first (and only) diesel in a pickup truck to come equipped with compound turbos, it had the largest capacity injection pump of its time, and with a few simple upgrades it could easily produce 500 horsepower at the wheels. Admittedly, that did require removing a few parts which is frowned upon, and over time, we learned that the 6.4 platform had a few shortcomings in the piston department which caused headaches for many owners. That’s a conversation for another time as a failed piston is certainly not an inexpensive or simple repair to make, but there are some upgrades you can do to your 6.4 Powerstroke that will solve problems and not cost an arm and a leg.

Radiator Time

One of the more common failures of the 2008-2010 6.4 Powerstroke is the radiator, and as you can imagine, its fairly important to keep your engine operating full of coolant and at the right temperature. The stock radiator is known to develop a leak where the plastic end tanks are crimped onto the aluminum core, but even the revised factory radiator is still problematic. A lifetime solution will cost a little more than stock, but a Mishimoto Heavy Duty Protection Bundle is well worth the investment. It replaces the radiator with an all-aluminum version that has welded end tanks that are guaranteed not to leak, and along with the radiator, the bundle includes silicone coolant hoses, a reinforced steel upper radiator support, new low and high temperature thermostats, and a new reservoir cap.

Transmission Reinforcements

Ford used the 5r110 transmission behind the 6.0 and 6.4 Powerstroke, and its remarkably strong when compared to the Allison and 48RE/68RFE used by GM and Ram during the same timeframe. Sure, it only had 5 forward gears, but in terms of overall strength it was unmatched. Although it was very rugged and reliable, there is one area that needs a little help when additional horsepower is thrown into the mix, and that is the direct clutch solenoid. Hydraulic fluid passes through the direct clutch solenoid when reverse and 5th gear are commended, and under heavy load, the stock solenoid doesn’t have adequate fluid volume to execute the 4-5 shift quick enough, which eventually leads to a smoked 5th gear clutch. The fix is greater fluid volume in that circuit, and an XDP Modified Direct Clutch Solenoid will provide just that. For $130 this simple solenoid easily installs into your valve body and will give your 5r110 a lot more holding power in 5th gear and can even save you from having to rebuild your transmission.

6.7 Powerstroke

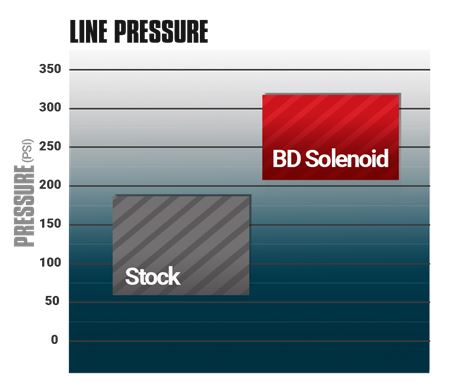

Until 2010, all Powerstroke engines were manufactured by Navistar International, but in 2011, Ford introduced their first in-house designed and manufactured diesel engine. Nicknamed the Scorpion due to its unique exhaust manifold and up-pipe combo, the 6.7 Powerstroke made more power than ever, and was a lot more reliable and efficient than its predecessors. It was backed up with a new six-speed automatic, the 6r140, and much like the 5r110 before, it was strong, but needed just a little help in the solenoid department. Main line pressure in the 6r140 is controlled by a solenoid inside the transmission, and the stock Ford version has an operating range between 60-180 psi. This is a little on the low side for performance and towing applications, and the lower pressure can cause clutch slippage and RPM flares between gear changes, which once again, can cause premature failure of the transmission. By installing a BD Diesel Pressure Solenoid in the 6r140, the operating range of the line pressure is bumped to a max of 320 psi which will give you firm and quick shifts in every gear, which means no more slip, and a longer life from your transmission, and it will operate without requiring special tuning or setting any trouble codes.

Keep Your Ford on the Road

Ford is America’s number one selling truck, and there’s no denying they make a good looking and solid performing pickup. No matter which one you own, there are always a few problems that will come up from time to time, and rather than replace a faulty part with another one that will be equally likely to fail in the future, I always try to upgrade with fixes and improvements that will enhance the driving experience, eliminate future problems, and increase the performance of the truck overall. These simple and cost-effective parts will make your truck more enjoyable to own, and even save you money in the long run, which you’ll need as fuel prices continue to rise.

Screw all the haters, their just mad their trucks don’t sound like a big turbo straight piped 6.0

I have all those upgrades but you forgot the lees power steering steers like Cadillac