If you spend any time watching YouTube or reading the forums, you’re certainly aware the highest performance diesel builds are usually based on the common rail Cummins. For the last four years in a row, the overall winner of the Ultimate Callout Challenge has driven one, and in 2019’s competition, the top seven trucks on the dyno all had a Cummins under the hood, and they ALL made over 2,000 horsepower. There’s no disputing the fact the legendary inline six can make some steam, but what does it take to build one?

Start at the Bottom

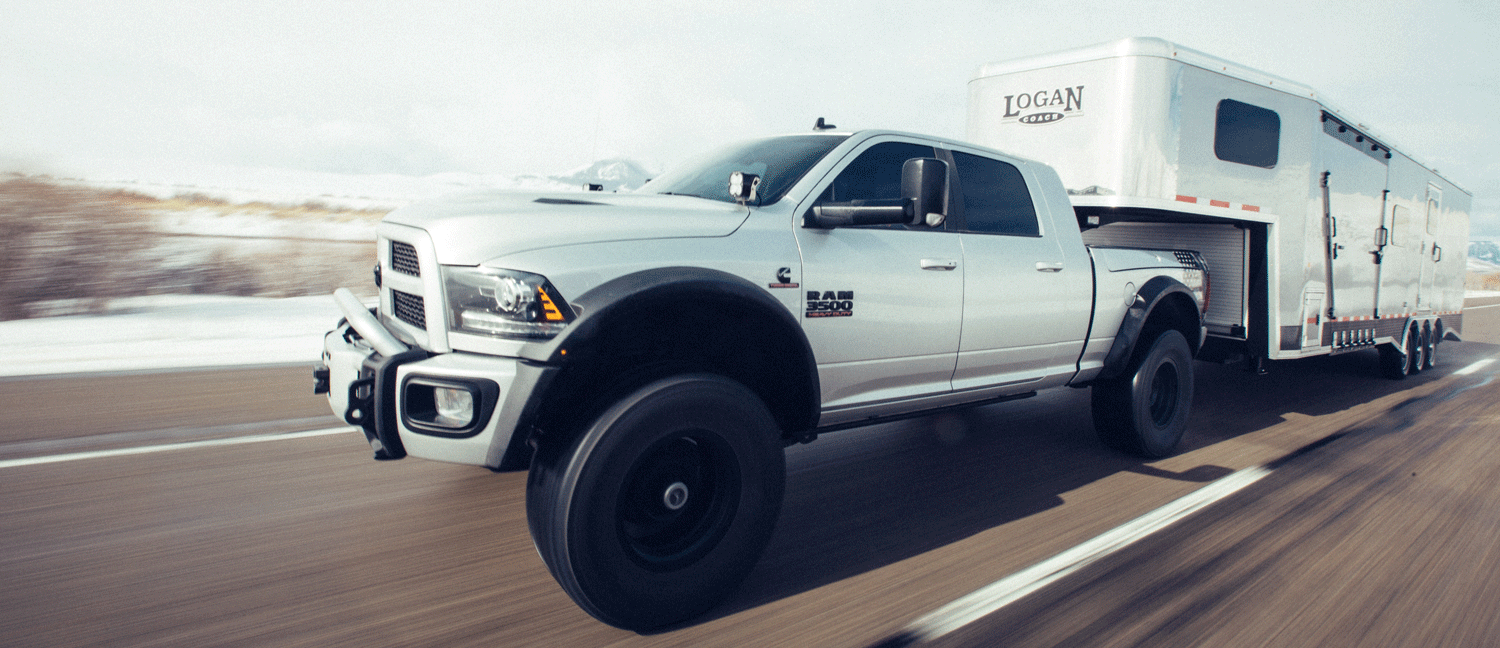

Starting in 2003, the standard output 5.9 liter common-rail Cummins produced 235hp and 460lb.ft. of torque, and the high-output version of the same year made 305hp and 555lb.ft. Halfway through 2007, the larger 6.7 liter model was released which was rated at 350hp, and brand new 2019 models are available with 400 horsepower and 1,000 pounds of torque, which makes Ram the first automaker to release a pickup truck with a four digit torque rating. If you want to move Mt. Rushmore on the back of your gooseneck, the Ram will get the job done. But if you want to go fast, you need to bump those numbers a bit further.

There are tons of speed parts out there for the Cummins, and it can be difficult to determine which ones you need, and in what order to install them. Depending on who you ask, you’ll get different opinions on what order is best, but one thing is for sure: if you put the cart before the horse, you can certainly do damage to your engine. The horsepower figures we’ll be referring to are all at the rear wheels, and we’ll mostly be dealing with round numbers since every year of truck is different. We’ll go through the steps required to build a stock truck into a monster, talk about the parts needed to make it happen, and why those parts are important.

Stage One: 430HP

Even before the warranty is up, most owners will perform what I consider a “stage one” set of upgrades. There is minimal work required, and its all about getting a little more air into and out of the engine. The additional airflow will prepare the engine for a performance tune which is where the majority of the power will come from. You’ve no doubt heard it before, but cooler air is denser, and denser air can make more power; that’s the whole name of the game. A cold air intake system from S&B starts with the largest and freest flowing filter possible and isolates it from engine bay heat in a sealed airbox, which is fed by cool outside air. When combined with a larger and freer flowing intake tube, the turbo will have all the cold air it can ask for, and the engine can operate to its full potential, giving a touch more power and fuel mileage. Plus, you can select a reusable oiled filter, or a dry filter if you prefer.

On the opposite side of the turbocharger, we need to deal with the spent gasses. The stock exhaust system does a great job of restricting flow and keeping noise down, but it’s time to let that Cummins breathe. It’s a very easy job to replace the whole system from the turbocharger to the tail pipe, and it’s smart to install the system which supports the final amount of horsepower the truck will make. There are really two options for tube diameter, 4 or 5 inches. The internet will tell you a 4” exhaust will make more low-end torque since a turbo “needs more back pressure” to operate at low engine speed. I’m here to tell you that’s FALSE. A turbo does not need any restriction, in fact, the less restriction the better. The main tradeoff between the two sizes is sound, and the total amount of power it can support. If you plan on making anything less than 600 horsepower, a 4-inch exhaust will be adequate. However, if you want to run a 5-incher on your near stock truck, there’s no reason you can’t. Just be prepared for a little more up-front cost, a little more weight, and some more noise. Either size you choose will result in an increase in power, lower EGT, and an increase in fuel mileage. A great high flow system which will last throughout all stages of the build would be a 5” MACH Force XP turbo back kit from AFE. It’s made from stainless steel, so you know it wont rust out, has a high flow muffler to keep the noise at a respectable level, and it even includes a polished tip for good looks.

Finally, we get to programming, and this is where the real power gains will come from. The ECM for the Cummins engine has gone through many changes throughout its production run, and each generation requires different “tools” or software to reflash the computer. If you are happy with a “stage one” type of build, a box programmer like an Edge or Bullydog will be all you need, however, if you want to push further, it’s a smart financial move to choose custom tuning which can grow with your build. For 2003 to 2007 5.9 trucks, one of the best custom tuning platforms is HP Tuners, and Ryan Milliken from Hardaway Performance can reprogram your ECM to meet whatever horsepower goals you have, even when starting with a bone stock truck. The best part about custom tuning is as you add more hard parts, it’s very a simple process to update the tune file to keep everything working in balance.

For later model trucks, its advantageous to use the EFI Live tuning platform, since it has the capability to switch between power levels on the fly with an optional switch. Calibrated Power provides their tunes on an Autocal device which you simply plug into the OBDII port and re-flash the computer. Once the CSP switch is installed, you can enjoy towing, daily driving, or racing, all with a clean running truck that gets better fuel mileage than stock.

Stage Two: 550HP

One accessory I consider to be necessary after stage one is a good set of gauges, with the two most important being a pyrometer and a boost gauge, as they are the best indicator of the health of your engine, and they give you a warning to take your foot off the accelerator if things get too hot. For a high-tech look you can install an Edge Insight CTS3 using an external sensor for the pyrometer, plus it will allow you to keep an eye on other parameters like injection timing, rail pressure, fluid temperatures, and a whole lot more.

Parts that Support Power

The parts for stage two are broken up into two separate categories: parts that support power and keep the engine together, and parts that add power through increased airflow. As a precautionary measure, I always recommend the “safety” parts first, which means its time to pull the valve cover off and take advantage of how easy it is to work on a Cummins. At a stock or mildly tuned power level the factory head bolts work great, but since it’s so easy for a Cummins to make a ton of horsepower and boost, the stock bolts will run out of strength, which is why it’s very common to see a tuned Cummins with a blown head gasket. To prevent that from happening, its necessary to swap out the head bolts with a stronger fastener, and the industry standard is a set of ARP Head studs. For most street trucks making under 800hp, the ARP2000 (rated at 220,000 psi tensile strength) studs will work great. For higher power levels, you should step up to the CA625 material. This does represent a pretty steep price jump, but the fasteners are rated at a much higher at 260,000 to 280,000 psi. After all, if your combustion pressure isn’t sealed inside the engine, you’re not going anywhere.

The valve spring is responsible for closing the valve, but it also has to push a rocker bridge, rocker arm, pushrod, and a tappet back down to the base circle of cam. There is a lot of mass to move, plus you have boost and exhaust drive pressure pushing against the backsides of the valves trying to work against the spring. When you combine that with higher RPM, the stock valve springs have a hard time keeping up, and if they cant close the valve in time, the piston will step in and do the job instead, which is not what you want to have happen. To keep the valves where they belong, stronger springs are in order, and it’s an inexpensive and worthwhile upgrade on any tuned Cummins. Hamilton 103 Pound Valve Springs will work much better than the stock 80-pounders and will keep the valves in place without putting too much pressure onto the cam lobes. Since you already have the valve cover removed to install the head studs, valvesprings will only add another hour or two to the job. The final upgrade I’d do while under the valve cover, is stronger pushrods. Since they are so long and made from thin wall tubing, the stock pushrods can bend due to the stronger valvesprings and elevated cylinder pressure, so an inexpensive upgrade to Hamilton Extreme Pushrods will keep you out of trouble. It will cost $630 for both valvesprings and a set of pushrods, but its honestly cheap insurance.

Parts that Add Power

Now that the valvetrain is stabilized and the head is clamped to the block, its time to add a bit more air into the mix. On the driver’s side of the engine, the stock intake horn is very restrictive and only flows 432 CFM of air which becomes a bottleneck, so an easy and inexpensive solution is the Banks Monster Ram Intake and larger boost tube. You can get 3.5- or 4-inch version for your Cummins which will flow up to 1,008 CFM, feed more air into the cylinders, lowers air temp, and actually raise boost pressure without creating any additional exhaust back pressure.

It’s always smart money to upgrade the intercooler during stage two to pull more heat away from the air headed to the engine. The stock intercooler will flow a bit more than it was designed to, but once the boost is turned way up, the stock core becomes a restriction, creates a pressure drop, and is less efficient at removing heat. An AFE Bladerunner can flow 30% more air than stock and has 3/16” TIG welded end tanks, and since its rated at 200 psi it can handle any amount of boost you can pump into it.

Turbo Time

The turbocharger is very important when it comes to making power, and of course for stage two and beyond you’ll need a larger one, but the big choice is what type. When it comes to picking turbos for the Cummins, there are two separate schools of thought: those who recommend a 2nd gen swap, and those who prefer a stock 3rd/4th gen style. Each has its pros and cons, but first let’s explain what it all means. Common rail trucks from 2003 onward (3rd and 4th generation body style) mount the turbine housing between the 4th and 5th cylinder with the manifold discharge pointed straight down. This puts the turbo much lower in the engine bay and closer to the block. Though the manifolds from the 5.9 and 6.7 look nearly identical, they are slightly different. The 5.9s used a standard T3 flange, and the 6.7s used a slightly larger (but not T4) flange with the VGT charger. In both instances, the runners inside the manifold are restrictive, and the placement limits what turbochargers you can physically bolt up. A second gen swap will ditch the stock design, and instead uses an exhaust manifold designed to fit a 2nd generation 24-valve Ram from 1998.5 to 2002, where the turbine is centered between cylinders 3 and 4, and the manifold has more symmetrical look with even airflow between all the cylinders. The turbo is mounted higher and further away from the engine, which means you can install a larger and more durable S400 style of turbo, with plenty of size options for a range of power levels.

For simplicity sake, you can stick with the stock turbo placement since you’ll be able to re-use the exhaust system and cold air intake you already have, but the manifold itself should be swapped out for a higher flowing replacement like the BD-Power 2-piece exhaust manifold. It’s a direct replacement, will work with your emissions equipment, flows much better, and is made from a much thicker and more durable material so it won’t crack like the stock versions do. For the needed airflow, it can be paired with a BD-Power Screamer turbo, which is a modified VGT with a 64.5mm compressor wheel which will support nearly 700hp and still have excellent street manners and spool up, along with turbine braking ability which is a must if you still use your Ram to tow. If you want even more power potential without losing spool up or drivability, you can also add an Industrial Injection Add-A-Turbo Kit on top of your BD Manifold and Screamer turbo. It works in conjunction with a stock or modified VGT, still allows for all emissions components to operate, and you can install it in an afternoon with basic hand tools. If you have compounds on stock fuel with the supporting mods like studs and valvesprings, you’ll have almost no chance of hurting your engine, but you will max out around 550hp, since you’re fuel limited. But whenever you add more fuel later on, the compounds will really come into their element.

2nd Gen Baby

So, what about that 2nd gen swap? It too has its place, but you have to be willing to give up a few things, most notably, the stock variable geometry turbocharger and its wide power band, but if you’re chasing a quadruple digit power number, it’s a sacrifice you’ll have to make. One major factor for deciding between the two styles is driver preference. Some love the feel of a larger single charger, because instead of a smooth linear spool up, it’s a violent rush of power that hits all at once, and admittedly it’s a blast to drive. To get that S400 installed, you’ll have to ditch your stock manifold and turbo and start with a BD Iron Horn Series Turbo Kit. It can be configured in a variety of ways with your choice of manifold and turbo, but for a mild street build you could start with an S363 and cast manifold, or if you want to go nuts you can swap to an S369 SX-E . This means a single S475 is possible, but you wouldn’t want to run that on stock fuel since the spool up time would be pretty long. But whatever option you choose, stage two is all about getting more air into and out of the engine with less restriction, which paves the way for stage three.

Stage Three: 750HP

By now the head is clamped down tight, the valvetrain is stable, and there is plenty of cool air making its way into the engine, so the only thing missing is fuel. With the groundwork laid, it’s time to test the limits of your engine. The common-rail inline six has by far the stronge

st stock internals of the big three, but it’s far from indestructible. The earlier 5.9 sits at the top of the heap, and if a larger single turbocharger is used and low RPM torque is kept to a reasonable level, the connecting rods can survive in excess of 1,000hp. The later 6.7’s used a slightly weaker and more brittle connecting rod, and when combined with a VGT and aggressive tuning, massive low RPM torque can cause the rods to split and window the block, which is a very catastrophic (and expensive) failure. If you insist on low RPM boost and torque, a budget friendly upgrade is to install some shot-peened 12-vave connecting rods in your 6.7. Either way, a conservative number to shoot for would be between 750 horses and less than 1,400 pounds of torque at the wheels, and to get there we need a lot more fuel than the stock parts can supply. So, let’s start at the tank and work our way forward to the engine.

If you own a Ram, the easiest and simplest way to upgrade the lift pump is with a Fleece Powerflow in-tank lift pump assembly. It installs as a direct replacement to the stock pump and sending unit but has two electric fuel pumps mounted in the bucket. It will flow enough to support 800 horsepower, and will even work with a dual CP3 configuration, but the best part is since the fuel pump sits inside the tank, it requires no drilling to sump the tank, and its very quiet.

When it comes to high pressure fuel, the stock CP3 will throw in the towel somewhere around the 550hp mark. Although you may not need all 1,000hp worth of fuel, the most economical solution is a Deluxe Fleece Dual CP3 kit. It mounts a second belt driven CP3 pump to the engine and comes with a stock displacement CP3K pump which has been modified to supply fuel above 3,000 RPM. And because the fueling duties are now split between two pumps, each has much less work to do, so they will last for a very long time. And if one ever fails, you can simply replace it with an affordable stock displacement pump, rather than a pricey stroker CP3.

Finally, the valve covers need to come off one more time so we can throw some larger injectors into the engine. When choosing injector or nozzle size, you’ll want to keep your overall power goal in mind, and for that 800whp target, you’ll need about 80 percent more fuel than stock, and a BD-Power 180hp injector set will be just the ticket, since they flow 93% more fuel than stock, which wraps up stage three. This is what I would consider to be the upper limit of a “practical” hot street build. At this point you’ll still be able to drive the truck daily, tow a mild load, and have a ton of fun all at the same time. You can push things further however….

Stage 4: No Limits

Remember the trucks we talked about from the UCC? With seven rigs proving you can make over 2,000hp you can guess where this is headed, and that’s a blank check. Yes, you can take your regular 250k mile Cummins engine to the extreme, but all the parts we had for stage one, two, and three will be thrown out, and we need to start over. The engine has to come out to install stronger pistons and rods, custom machine work will need to be done on the head for more airflow, you want to throw in a larger cam, massive turbos, fire hose injectors, and a couple 14mm CP3 pumps fed by a pair of 200gph+ lift pumps. Is this all practical? Not exactly, but the better question is how fast do you really want to go?

The reality is most owners will stop somewhere between stages two and three. Maybe they have a modified single VGT and slightly larger nozzles, along with a few airflow and valvetrain upgrades, and are perfectly happy with 600 horsepower. When budgeting your build, don’t forget we totally skipped over the supporting mods, and even at 600hp, you’ll have a lot more work to make sure the rest of the truck survives at higher power levels, especially with an automatic transmission. Also, the brands and specific parts you choose may vary, as will your specific power output, but be smart about the order you install parts, avoid doing a job twice, and most importantly, keep an eye on that EGT gauge to keep your pistons happy and the rods inside your block. If you do all that, you’ll have a high power inline six which will put a smile on your face every day.

On a stage 2 upgrade would it be necessary to upgrade injectors or add a external fuel pump like air dog or fass? 2008 6.7 automatic mega cab.

Especially on a common rail Cummins, its never a bad idea to upgrade the lift pump with a FASS or AirDog for something simply more reliable and with increased filtration capability compared to the stock system. That said, you can “push” the upper boundaries of the stage 2 build as described in this article with the stock lift pump, but you’ll definitely be pushing it to its limit. I would recommend upgrading for anyone even running a chip or programmer on the upper power levels frequently to avoid failure of the stock pump, which will end up starving the CP3. For the injectors, you won’t really want to upgrade those until you’re getting more airflow via a larger turbo. The stock charger on the 6.7’s is already undersized to increase low end airflow, but the mid and top end is really limited, and adding more fueling will only cause higher EGT’s (exhaust gas temperatures) if running your programmer on higher levels, especially if the injector is larger than roughly a 50-60HP over stock.

Hey i wanna add size bigger turbo for my 5.9L Cummins what should i go with

Depending on your other modifications, and presuming you’ve got a 2003-2007 Cummins 5.9, the BD Super B is an excellent choice with great stock like spool up (quick), but with a big increase in mid and top end. This turbo works great for those that are running a chip or programmer, but stock size injectors. If you are running larger injectors, let us know what size, and we can recommend other options. Here’s a link to the Super B for the 2004.5-2007 model years, but if yours is another model year, let us know and we can shoot you the details for your exact truck.

https://www.dieselpowerproducts.com/p-3774-bd-super-b-single-turbo-045-07-59l-dodge-cummins-1045235.aspx

Info is great! I have a 2018 3500 Cummings with the Asian transmission. I like to have 500 to 600 hp and 1100 to 1400 of tq and better fuel mileage. What do I need to do it? Thank you!

Hi, I see Bobby Lincoln’s question there and I too have a 2018 Ram 3500 6.7 and I too would like as much horse power as we can get without any lower engine work if not nessary. 800hp 1400lbs of torque sound good. Can Bobby and I do it? And please we trust you. What exactly do we need to buy and in what order. Thank you!

For a 2018 Ram, we have found that the largest issue for trying to get to the 800hp mark is the bottom end. If you are not wanting to do any bottom end work, 550-600hp would be the max you would want to push it. We have seen the rods either bend, or break above the 600hp mark. With that being said a 550-600 hp truck is nothing to be ashamed of. Also you can make this horsepower level with all emission intact. Here are the parts that I would suggest for that horsepower in the order I would purchase in.

Intake:

https://www.dieselpowerproducts.com/sb-cold-air-intake-13-18-cummins

Lift Pump:

https://www.dieselpowerproducts.com/fleece-powerflo-lift-pump-67l-cummins

Tuner:

https://www.dieselpowerproducts.com/p-ez-lynk-auto-agent-2-by-calibrated-power-13-19-67l-ram-cummins

Fuel Plug:

https://www.dieselpowerproducts.com/p-11416-bd-common-rail-fuel-plug-075-18-67l-cummins-045-10-duramax.aspx

Exhaust:

https://www.dieselpowerproducts.com/p-11414-mbrp-5-dpf-back-single-outlet-exhaust-system-13-18-67l-cummins.aspx

Head Studs:

https://www.dieselpowerproducts.com/p-3705-arp-diesel-head-stud-kit-985-18-59l67l-dodge-cummins-247-4202.aspx

Turbo/Manifold (I would do these at the same time for ease of installation):

https://www.dieselpowerproducts.com/bd-screamer-he351ve-turbo-13-18cummins

https://www.dieselpowerproducts.com/bd-67l-exhaust-manifold-075-18-cummins

Injectors:

https://www.dieselpowerproducts.com/p-17759-dynomite-diesel-brand-new-no-core-50-horsepower-15-over-injector-set-13-18-67l-ram-cummins.aspx

CP3 Pump:

https://www.dieselpowerproducts.com/fleece-cp3-injection-pump-67l-cummins

Intercooler:

https://www.dieselpowerproducts.com/banks-25987-techni-cooler-intercooler

Tuning would have to be updated for the new injectors and turbo. All of these parts will allow your factory emissions to function as normal all while making that 550-600hp mark.

Now, of course, the transmission will have to be upgraded to handle this level of power. If you have the 68RFE we have complete transmissions, and or upgraded parts. If you have the G56 manual trans, clutch will have to be upgraded. Last but not least if you have the Aisin automatic, there is really nothing available for those other than a thermal bypass. We have had Aisin trans equip trucks here running at the 600hp level and they seem to hold pretty well.

68RFE Options:

Full Transmission:

https://www.dieselpowerproducts.com/bd-trans-converter-075-18-cummins

Upgrade your current trans:

https://www.dieselpowerproducts.com/p-bd-1061528-68rfe-thermostat-bypass-13-18-67l-ram-cummins

https://www.dieselpowerproducts.com/bd-power-deepsump-transpan-67l-cummins

https://www.dieselpowerproducts.com/p-ats-68rfe-complete-billet-channel-plate-075-18-ram-67l-cummins

https://www.dieselpowerproducts.com/p-7796-bd-triple-torqueforce-converter-075-18-67l-cummins-68rfe.aspx

https://www.dieselpowerproducts.com/p-17532-bd-1062036-68rfe-big-stack-shaft-and-drum-kit-075-18-67l-dodge-ram-cummins.aspx

Aisin:

https://www.dieselpowerproducts.com/p-bd-1061528-68rfe-thermostat-bypass-13-18-67l-ram-cummins

G56 Manual:

https://www.dieselpowerproducts.com/p-7959-south-bend-clutch-street-dual-disc-055-18-59l-67l-cummins-g56-6-speed.aspx

For further info, I would suggest giving one of our knowledgeable sales techs a call. They can certainly answer further questions and or get an order started for you!

What would you recomend for a 2002 Dodge Ram in terms of getting to Stage 2?

Thanks for reading our blog and for the inquiry. On a 2002, many of the same principles will apply, but obviously a slightly different parts list for the VP trucks. I’ve personally had two 2001’s that were at that rough power level, and found a great combination especially on the second one. I’ll touch base mostly in regards to the engine, but you’ll need to ensure you’ve got the transmission (or clutch) to support that power level. Here’s a good list to shoot for based upon my experience:

Smarty S03 Programmer: https://www.dieselpowerproducts.com/smarty-s03-programmer-985-02-cummins

Stacked with an Edge Comp Box: https://www.dieselpowerproducts.com/edge-comp-box-cummins-30300-30301

Dynomite Diesel 125 Horsepower Injectors (I ran 125’s, which net a little over 500 horsepower. If you’re wanting 550, then I’d go with their 150 horsepower injectors): https://www.dieselpowerproducts.com/dynomite-diesel-125hp-injector-cummins

FASS Titanium Lift Pump: https://www.dieselpowerproducts.com/fass-ts-d07-100g-fuel-liftpump-cummins

S&B Cold Air Intake: https://www.dieselpowerproducts.com/sb-coldairintake-system-94-02-cummins

Banks Intake Manifold: https://www.dieselpowerproducts.com/banks-power-intake-manifold-59-cummins

Mishimoto Intercooler: https://www.dieselpowerproducts.com/p-mishimoto-intercooler-kit-94-02-dodge-59l-cummins

BD Super B Special Turbo: https://www.dieselpowerproducts.com/bd-sx-e-s363-turbo-kit-94-02-cummins

BD Exhaust Manifold: https://www.dieselpowerproducts.com/bd-exhaust-manifold-985-02-cummins-24v

Diamond Eye 4″ Turbo Back Exhaust: https://www.dieselpowerproducts.com/diamond-eye-k4212a-turbo-back-exhaust

You can also check out our various “Recipes for Horsepower” that we’ve put together for various power goals: https://www.dieselpowerproducts.com/c-2321-94-02-59l-24v-recipes-for-horsepower.aspx

I would recommend starting with the exhaust, intake, Smarty, FASS, and get your transmission in shape. From there, add the Edge Comp Box and turbo, followed shortly by the injectors and then get your airflow in order with the intercooler and intake manifold. Good luck, and let us know if you’ve got any other questions!

Trying to get a close guess on HP. 2006 ram 2500 5.9. ARP studs,90 over inj.nozzles, air dog fuel system,upgraded cp3 (bag of parts),K&N air intake system,B&D super B single, 4 inch straight to rear bumper. EdgeCS, ATS Stage4 transmission. Truck is super fast and fuel efficient. I live in the middle of nowhere so looking for approximate HP rating without shipping the truck somewhere. Any additional upgrades you suggest? Thanks for your time and advice

Hi there and thanks for the question. I’m going to presume that when you say you’ve got an Edge CS that its a Juice with Attitude (not an Evolution or just the Insight monitor), and that you have not done the optional Level 6 Unlock. That said, without knowing tire size or gear ratio, I would guess that your truck is putting to the ground about 500-520 horsepower. If you did have the Level 6 Unlock from Edge, then I’d put you closer to about 550 at the ground. Hope this helps and let us know if you have any other questions.

Hey Josh, I have a ‘12 dually 6 sp. I have a torque tech T1 that I’ve never taken off of stock, 5”tbe, s&b cai, sinister egr/cooler delete, and a south bend dual disc clutch. I believe my head gasket is going out, so I’m going to get ARP 625+ studs and probably a Mahle gasket. Basically, I was to know if springs and push rods are a necessity. I don’t know where I will stop with my builds, but definitely won’t be pulling professionally. I want to turn my tuner up, but I’m afraid to. If I run it on the hot setting will I be digging myself into a hole? Thanks.

So…what can I do with my 2004 Dodge w/ 5.9 to add power and still stay California legal?

I have a 06 5.9 and fixin to have the motor rebuilt [198k). I’ve only done the upgrade to the cold intake. I plan on replacing the oil pump, add head studs. Is there anything else I should replace while I have it apart? I can’t spend crazy money on. I tow a 30ft travel trailer mostly. I’m looking for power but want my mpg to go up.

This is a great article, and contains a LOT of good information.

I have a 3 gen CR truck, and the biggest and most valued mod to support all that you’ve said in the article is a COLT stage 3 or 4 camshaft.

The factory cam in these engines has a bad exhaust valve overlap to support emissions and it chokes your engine.

Any 5.9 CR and 6.7 use this I-EGR cam, and it will hold back all of your other mods.

So I’m looking to get more top end speed. Currently im at about 2000 Rpms at 70mph. I have a 2015 6.7l 4wd with a g56 manual and 3.73 gears in the rear and 33in tires. The truck is deleted and tuned and 4 in exhaust all the way from turbo, afe cold air intake, and edge insight. I was looking at suncoast transmission but they push the 68rfe and ATS that run Allison’s. I would like to keep it a manual or slap shifter if possible. Any advice or part lists would be greatly appreciated.